Cover structure for improving cooling efficiency of horizontal gas film on downstream of open slotted hole

A technology of air film cooling and slotted holes, which is applied in the direction of supporting components of blades, engine components, machines/engines, etc., and can solve the problems of insufficient collection of cooling air, raising cooling air, and hindering the flow of cooling air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

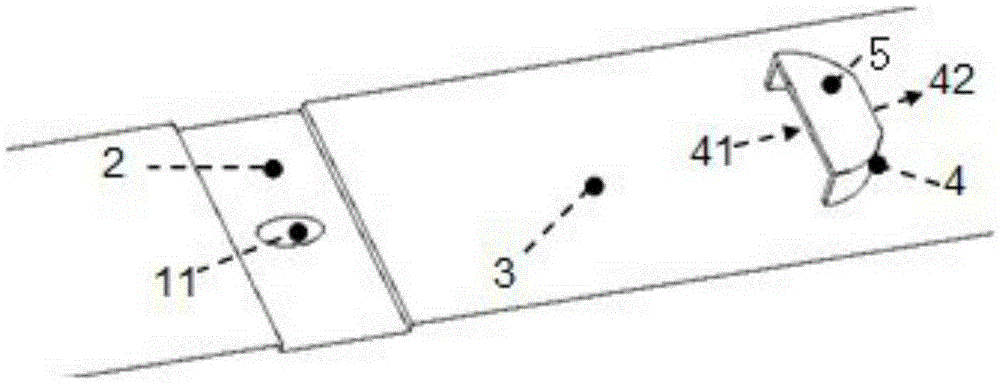

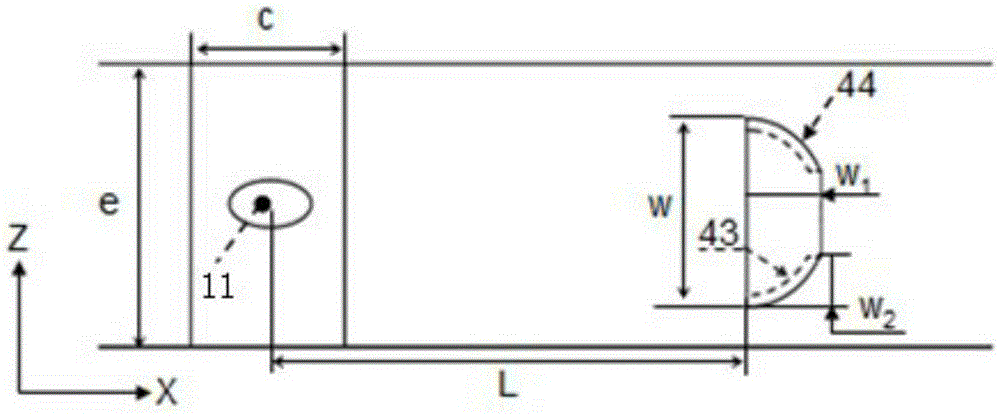

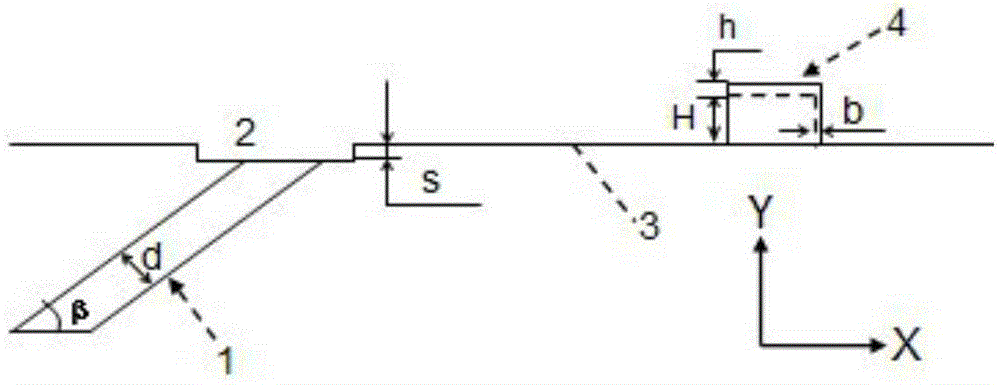

[0033] This embodiment improves the cover structure of the downstream transverse air film cooling efficiency of the slotted hole (see Figure 1-3 ) includes air film hole 1, transverse groove 2, wall 3, protrusion 4 and capping 5, the upstream area of wall surface 3 is provided with air film hole 1, transverse groove 2 is provided at air film hole outlet 11, and protrusion 4 In the downstream area of the wall surface 3, the protrusion is two brackets, and the two brackets are symmetrically arranged perpendicular to the wall surface 3 with the central line of the gas film hole as the axis, and the convex air inlet 41 is facing the direction of the gas film hole, and the back The direction of the air film hole is a raised air outlet 42, the profile line of the projection 4 facing the direction of the film hole is the windward profile 43, and the profile line facing away from the direction of the film hole is the back pressure profile 44 of the projection 4, The windward prof...

Embodiment 2

[0040] In this embodiment, the position and connection relationship of each part in the cover structure for improving the efficiency of lateral air film cooling downstream of the slotted hole are the same as in Embodiment 1, except that the protrusions 4 are two prism-shaped arcs (see Figure 8 ), the capping is a non-smooth curved surface shape, and the two sides of the capping are fixedly connected with the tops of two prism-type arcs respectively, and the thickness of the capping 5 is the aperture of the gas film hole 1 of 1 / 10.

Embodiment 3

[0042] In this embodiment, the position and connection relationship of each part in the cover structure to improve the efficiency of lateral air film cooling downstream of the slotted hole is the same as that of Embodiment 1, the protrusion 4 is two brackets, and the difference is that the capping is a smooth arc. surface (see Figure 9 ), the two sides of the capping are respectively fixedly connected with the tops of the two brackets, the thickness of the capping 5 is the aperture of the gas film hole 1 of 0.05, and the distance from the highest point of the capping 5 to the wall 3 is the height of the protrusion 4 2 times.

[0043] The unmentioned parts of the present invention are applicable to the prior art, especially the prior patent application of the applicant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com