Two-channel gear-shift transmission separating gearbox and control method thereof

A transmission separation and dual-channel technology, which is applied in the field of gearboxes, can solve the problems of large gear speed differences, increased volume and cost, and loss of driving force, and achieve the effects of reduced volume, stable power, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

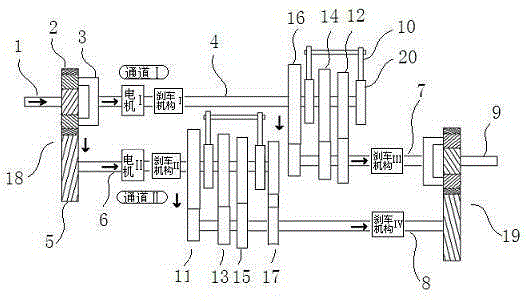

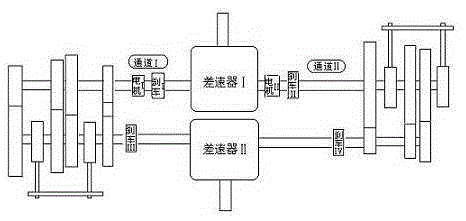

[0030] attached figure 1 It is a specific embodiment of the present invention, which includes an input shaft 1, an output shaft 9, and a transmission and speed change mechanism between the input shaft and the output shaft, and is characterized in that: the transmission and speed change mechanism is provided with a Two channels are used to realize the separation of transmission and shifting between the input shaft and the output shaft; the channel I includes the main shaft assembly I4, the auxiliary shaft assembly I7 and the shifting mechanism, and the channel II includes the main shaft assembly II6, auxiliary shaft assembly Shaft assembly II8 and shifting mechanism, wherein, the main shaft assembly I and the auxiliary shaft assembly I are respectively equipped with a brake mechanism I and a brake mechanism III, and the main shaft assembly II and the auxiliary shaft assembly II are respectively equipped with There are brake mechanism II and brake mechanism IV; the planetary gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com