Pipe system hanging device of coal economizer

A technology of economizer pipe and hanging device, which is applied in the direction of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the fatigue cracks of pipe clamps and header welds, and the inability of economizer pipes to pass through ventilation beams. Problems such as hanging, falling of pipe system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

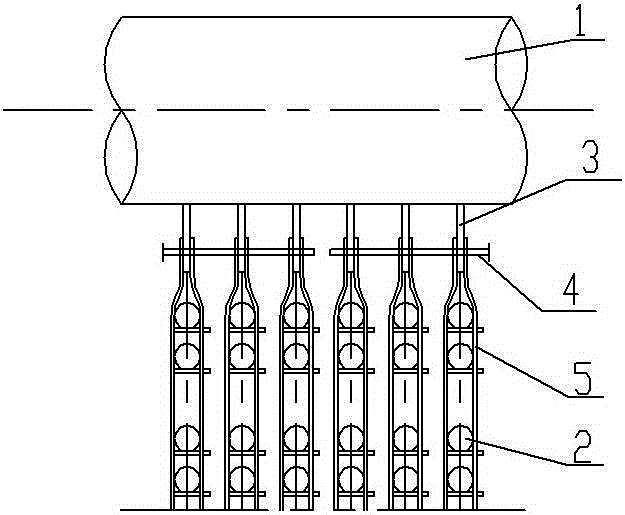

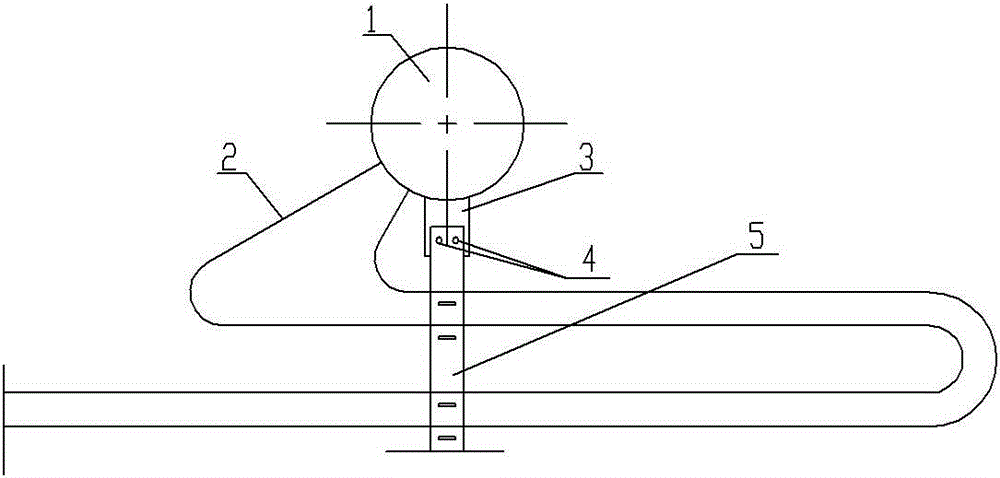

[0011] See figure 1 , figure 2 As shown, an economizer pipe system hanging device includes an upper header 1, a pipe clip 5 is arranged at the lower end of the upper header 1, an economizer pipe 2 is arranged inside the pipe clip 5, and the bottom of the upper header 1 is fixed A pre-embedded steel plate 3 is installed, and the pre-embedded steel plate 3 and the top of the pipe clamp 5 respectively have matching fixing holes, and the round steel 4 is welded through the fixing holes.

[0012] Six pre-embedded steel plates 3 are fixedly installed at the bottom of the upper header 1, and six corresponding pipe clamps 5 are installed at the lower end of the upper header 1, and each round steel 4 runs through three pre-embedded steel plates 3, and the round steel 4 and the pipe clamp 5 Solder connection on top.

[0013] Each pre-embedded steel plate 3 and the top of the pipe clamp 5 are respectively provided with two fixing holes, and each fixing hole runs through the round stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com