LED lamp with water-proof and dust-proof function

A LED lamp, waterproof and dustproof technology, which is applied in the direction of air-proof/waterproof devices, components of lighting devices, cooling/heating devices of lighting devices, etc., can solve problems such as unstable quality, poor light quality, and insufficient performance. Achieve good heat dissipation stability, increase heat dissipation effect, and increase heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

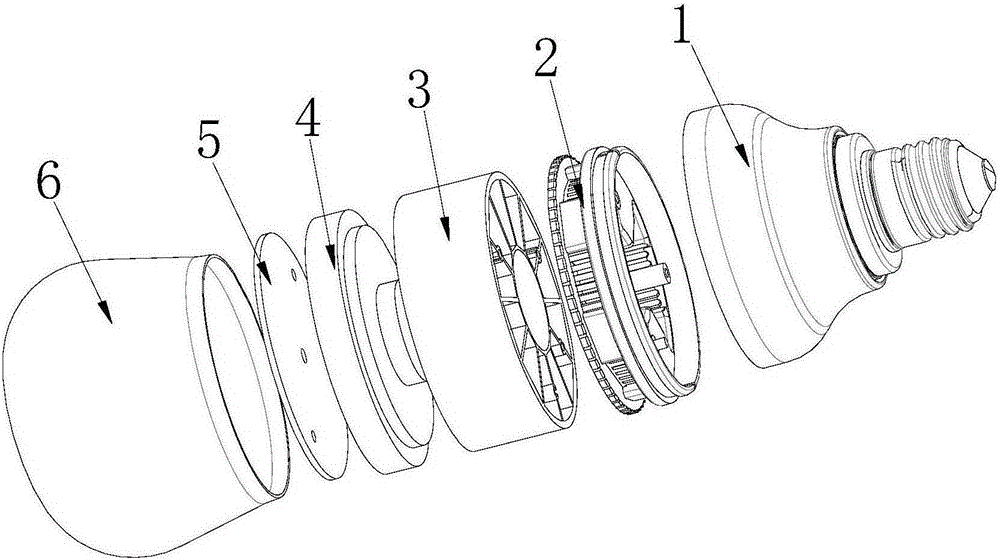

[0039] Such as figure 1 The LED lamp shown includes a lamp cap 1 , a connector 2 , a heat sink 3 , an isolation block 4 , a light source board 5 and a lampshade 6 . The connecting piece 2 is located between the lamp cap 1 and the heat sink 3 , and is used for connecting the lamp cap 1 and the heat sink 3 . The isolation block 4 is located between the heat sink 3 and the lampshade 6 for connecting the heat sink 3 and the lampshade 6 . The light source board 5 is installed on the isolation block 4 and is on the side facing the lampshade 6 .

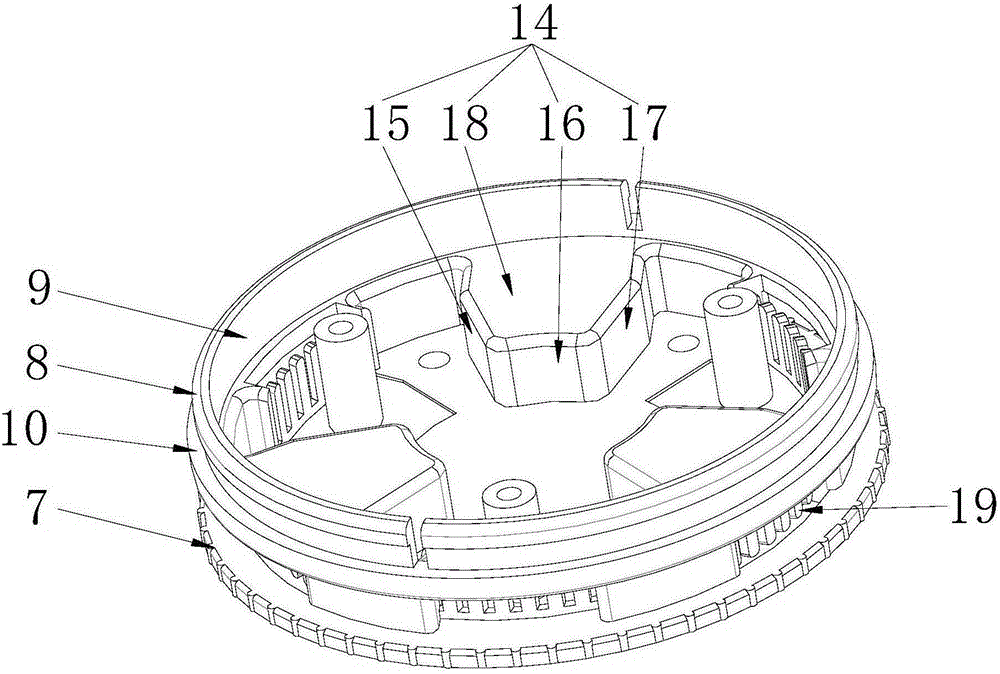

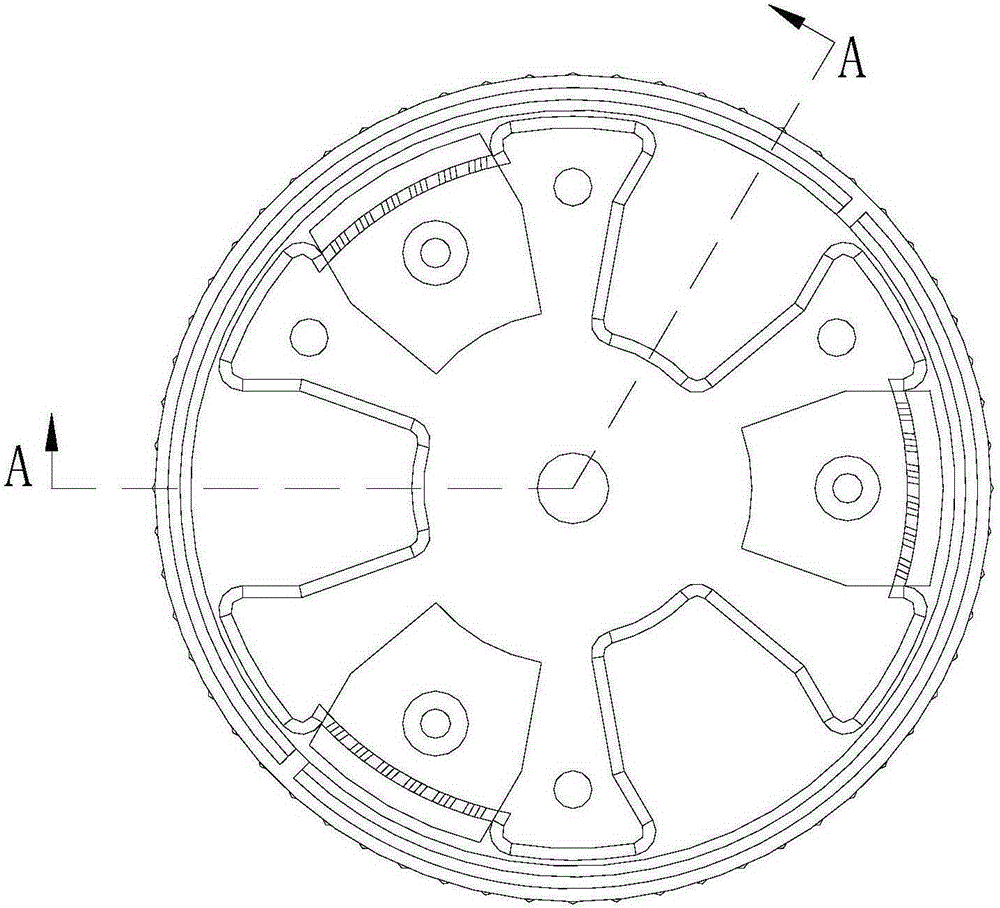

[0040] Such as Figure 2-5 , 11, in this embodiment 1, the outer contour of the connecting piece 2 is cylindrical, and the connecting piece 2 includes a bottom plate 7 and a connecting block 8 . In the first embodiment, the outer contour of the bottom plate 7 is cylindrical, and a connecting block 8 with a cylindrical outer contour is connected to the bottom plate 7 . An accommodating cavity 9 is formed in the connection block 8 . Alon...

Embodiment 2

[0047] The difference between this embodiment 2 and embodiment 1 is that, as Figure 12-15 As shown, in the second embodiment, three third exhaust holes 33 are provided on the connecting block 8 along the circumference of the connecting block 8 , and the third exhaust holes 33 communicate with the accommodating cavity 9 . The third exhaust hole 33 communicates with the accommodating chamber 9 to form a second air channel of the air convection element. A blocking block 19 is also arranged in each third exhaust hole 33 , and the blocking block 19 is located in the protective edge 10 , and the air vent 22 is also formed on the blocking block 19 . The protective edge 10 protects the blocking block 19 to prevent the blocking block 19 from being damaged due to external force collision. In order to prevent foreign objects from easily entering the accommodating cavity 9 , the height of the blocking block 19 can be greater than the height of the third exhaust hole 33 . Several air ho...

Embodiment 3

[0049] The difference between this embodiment 3 and embodiment 2 is that, as Figure 16-18 As shown, in the third embodiment, the base plate 7 is provided with a first ventilation hole 35 . The first ventilation hole 35 communicates with the accommodating chamber 9 and communicates with the inner tube 25 of the cooling seat 3 , constituting the third air channel of the air convection element. In addition, a second ventilation hole 36 is provided on the isolation block 4 , and the second ventilation hole 36 runs through the entire isolation block 4 and communicates with the inner tube 25 of the heat sink 3 . The light source board 5 is provided with a process hole, so that the second ventilation hole 36 can communicate with the inside of the lampshade 6 . When the LED lamp is working, after the air in the lampshade is heated, it can enter the inner tube of the heat sink along the second ventilation hole 36, and enter the third air flow channel through the first ventilation hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com