Vapor compression-jet coupled refrigeration cycle device and method

A refrigeration cycle and steam technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of increasing compressor power consumption, reducing evaporator heat exchange efficiency and cooling capacity, etc., to reduce gas transmission volume, The effect of reducing power consumption and improving cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

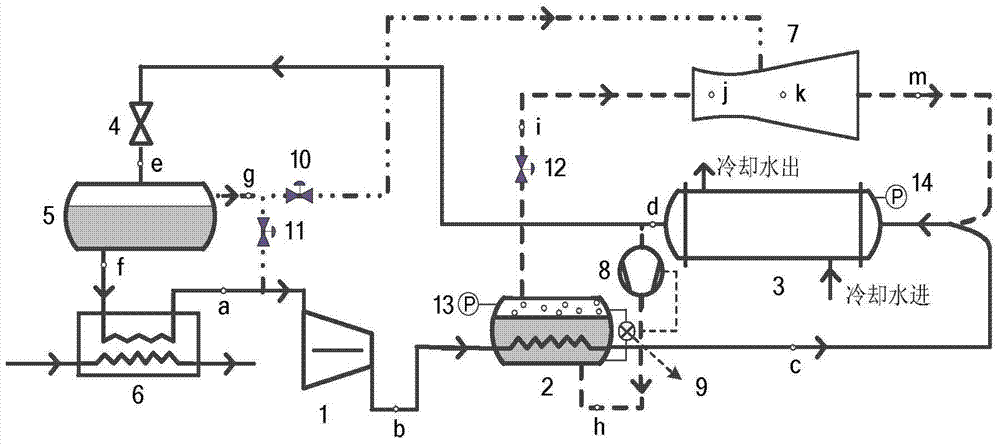

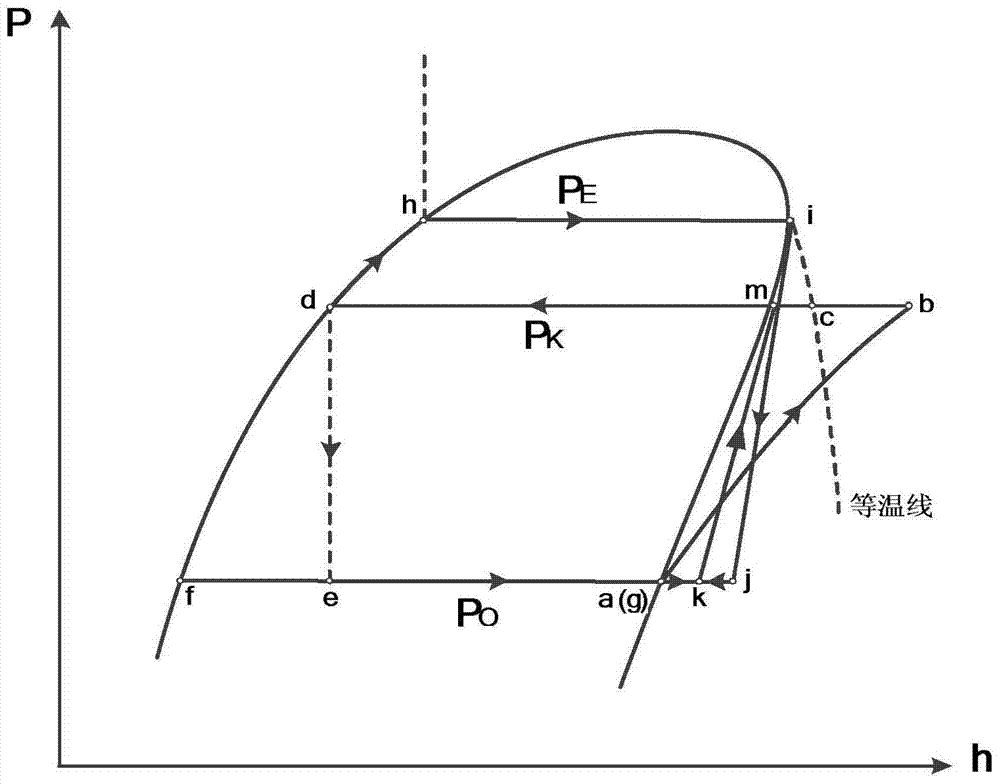

[0015] Compared with the ordinary refrigeration system, a vapor compression-jet coupled refrigeration cycle device utilizing the exhaust sensible heat of the refrigeration compressor of the present invention increases:

[0016] A gas-liquid separator for separating the flashed gaseous refrigerant after throttling;

[0017] A booster pump for boosting the pressure of the condensed liquid refrigerant;

[0018] A liquid level controller for sensing the liquid level of the generator and controlling the start and stop of the booster pump;

[0019] A steam generator set up to use the sensible heat of the exhaust of the compressor to generate higher pressure working steam for the operation of the ejector;

[0020] Ejectors for injecting throttling flashed gaseous refrigerant;

[0021] Several solenoid valves for switching processes and controlling flow;

[0022] Several pressure transducers are used to measure the pressure of the container.

[0023] This system can effectively im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com