An anti-surge compression cycle device and process that can adjust the cycle ratio of the synthesis loop

A technology of synthesis circuit and compression cycle, which is applied to components of pumping devices for elastic fluids, feeding devices, preparation of organic compounds, etc., can solve problems such as inability to change significantly, waste energy and gas volume, etc., to increase energy Consumption, reduce production, increase the effect of synthetic product content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

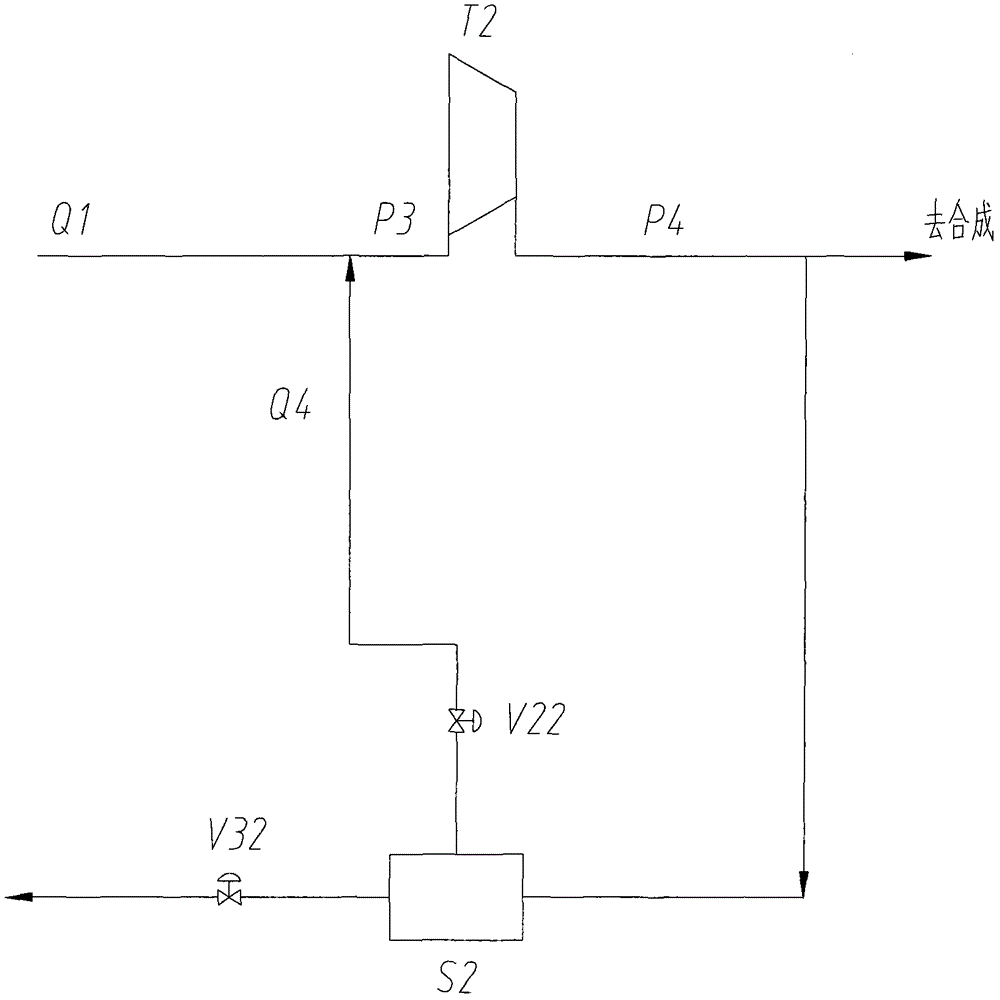

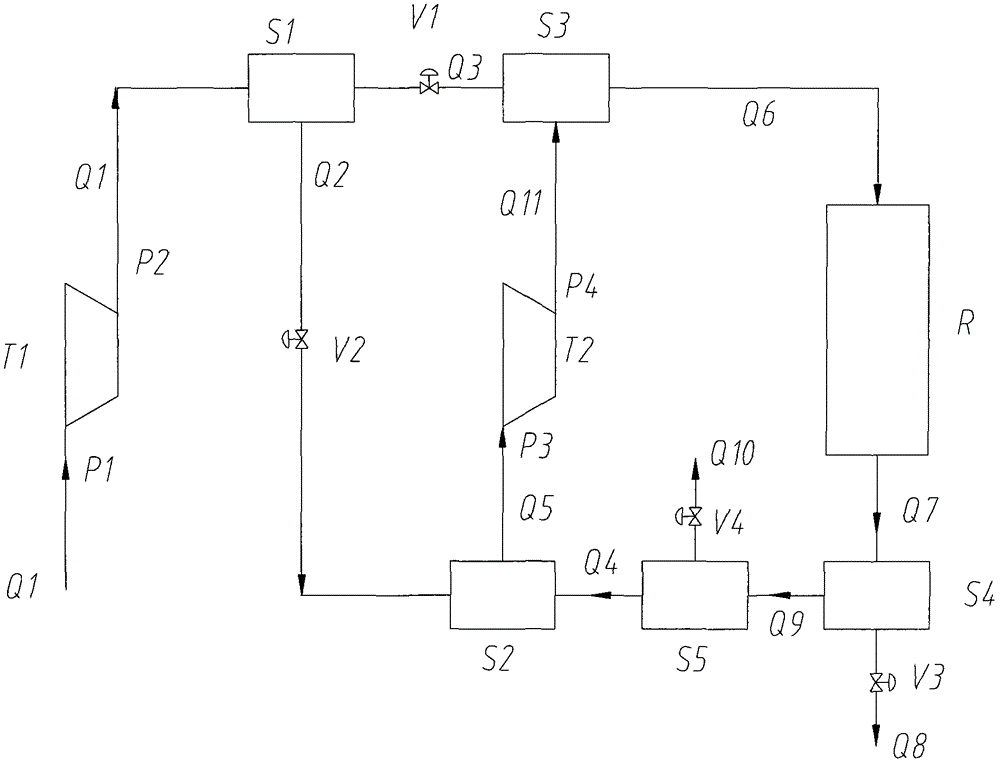

[0029] Such as image 3 The shown anti-surge compression cycle device that can adjust the circulation ratio of the synthesis loop includes compressor T1, flow splitter S1, outlet mixer S3 of the circulation section, synthesis reactor R, reaction gas-liquid separator S4, and relaxation gas separation S5, the inlet mixer S2 of the circulation section and the circulation machine T2, the outlet of the splitter S1 is provided with two, that is, the first outlet and the second outlet, and the inlet mixer S2 of the circulation section is mixed with the outlet of the circulation section There are two inlets of the device S3 respectively, that is, the first inlet and the second inlet.

[0030] The outlet of the compressor T1 is connected to the inlet of the splitter S1, the first outlet of the splitter S1 is connected to the first inlet of the mixer S3 at the outlet of the circulation section, and the outlet of the mixer S3 at the outlet of the circulation section is connected to the s...

Embodiment 2

[0040] The composition and connection of the device are the same as those in Example 1. Taking methanol synthesis of 600,000 tons / year as an example, using the above-mentioned device, Table 2 shows the two working conditions of mixing after the cylinder, that is, the second regulating valve V2 is closed, and the first regulating valve V1 is closed. When it is turned on, all the fresh gas Q1 from the outlet of the compressor T1 and the outlet gas Q11 of the cycler from the outlet of the cycler T2 pass through the outlet mixer S3 of the cycle section to form the tower gas Q6 and go to the synthesis reactor R:

[0041] Table 2 Data of mixed working conditions after the cylinder

[0042]

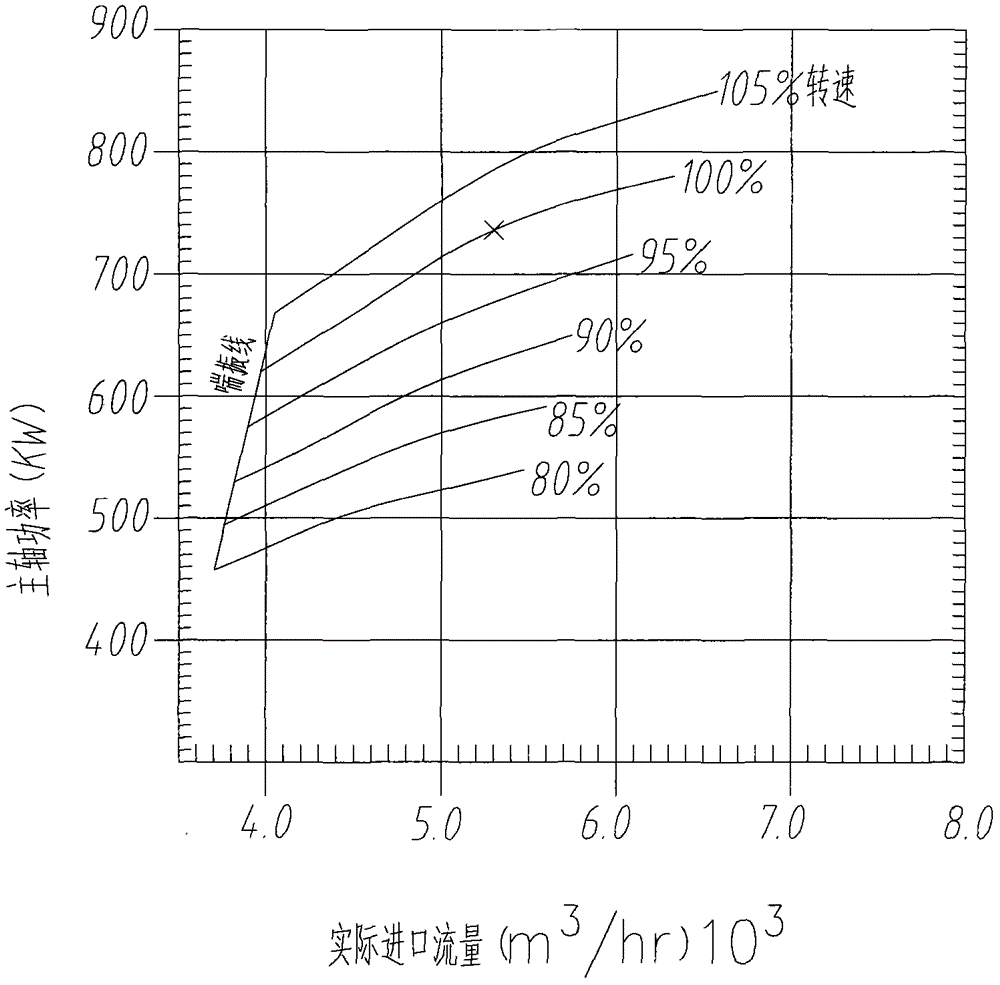

[0043] The volume of fresh air Q3 in working condition 3 is increased to 29.25×10 4 N m 3 / h, the air volume of Q5 at the inlet of the circulator is 60.5×10 4 N m 3 / h (working condition three is 60.5×10 4 N m 3 / h is the design value of the intake air volume of the circulator), after th...

Embodiment 3

[0046] The composition and connection of the device are the same as those in Example 1. Taking methanol synthesis of 600,000 tons / year as an example, the above-mentioned device is used, and the designed air intake of the cycler is 80×10 4 N m 3 / h, working condition five (as shown in Table 3) is: fresh air Q1 volume 39×10 4 N m 3 / h, all fresh cylinders are mixed before the cylinder, and the gas volume of the circulating gas Q4 is still 60.5×10 4 N m 3 / h, the air volume of Q5 at the inlet of the circulator reaches 99.5×10 4 N m 3 / h, 24% more than the design air intake of the cycle machine (generally, the actual maximum air delivery should be 110-120% of the design value), and the equipment is overloaded.

[0047] At this time, the cycle ratio can be adjusted by opening the first regulating valve V1 and diverting part of the fresh air Q3 to the outlet mixer S3 of the circulation section (see the working condition six data in Table 3). The specific operations are as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com