Measuring device for gas parameters of water-bearing coal seam by dynamic balance method

A coal seam gas and dynamic balance technology, which is applied in the field of devices for measuring borehole gas pressure, borehole gas gushing volume, and borehole water gushing volume. Accurate, gas is not easy to release and other issues, to achieve the effect of convenient debugging, increased safety, and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

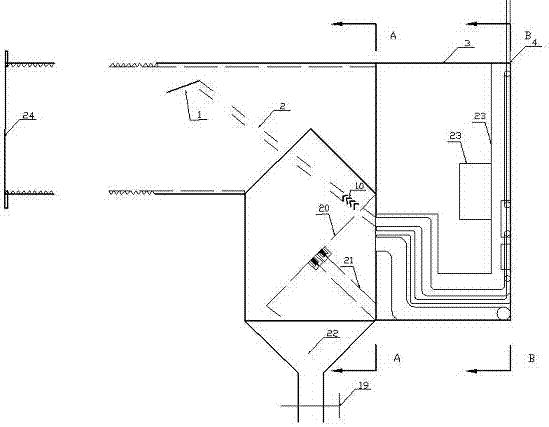

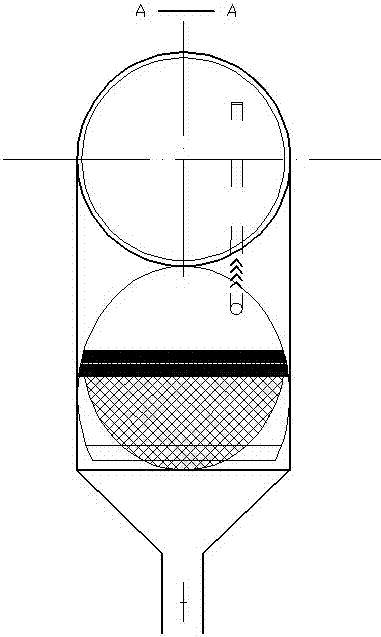

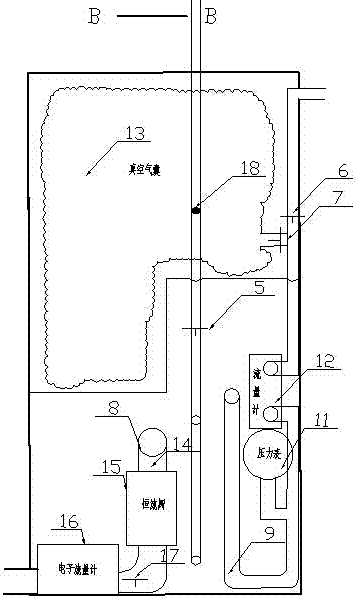

[0020] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0021] A device for measuring gas parameters in water-bearing coal seams by the dynamic balance method is composed of an exhaust pipe inner nozzle 1, an exhaust pipe inner pipe 2, an operation box 3, a liquid level indicating pipe 4, a liquid level indicating pipe valve 5, a gas discharge pipe valve 6, and a gas discharge pipe valve 6. Collection pipe valve 7, leak-proof rubber sleeve 8, exhaust pipe outer pipe 9, angle adjustment joint 10, pressure gauge 11, rotameter 12, vacuum air bag 13, drain pipe 14, constant flow valve 15, electronic flowmeter 16, Drain pipe valve 17, float 18, mud discharge valve 19, water guide plate 20, filter steel mesh 21, coal slime sedimentation tank 22, dividing plate 23, exchangeable butt joint 24 is formed. The gas parameter measuring device of the water-bearing coal seam by the dynamic balance method adopts an exchangeable dock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com