Reflective luminous filament and preparation method thereof

A filament, reflective technology, applied in optics, optical components, instruments, etc., can solve problems such as non-self-illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

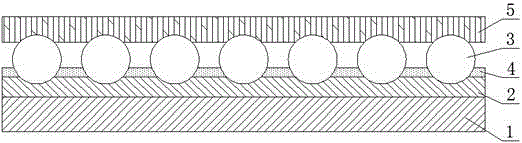

[0023] A kind of reflective luminous silk and preparation method thereof, such as figure 1 shown, including the following steps:

[0024] Step 1: Coating light curing agent layer 2 on PET film 1, the thickness of light curing agent layer 2 is 25 μ m, wherein the weight of polyester glue, diluent, adhesive agent, curing agent and fluorescent luminescent agent in light curing agent layer 2 The matching ratio is 5:1:2:2:3;

[0025] Step 2: After the photocuring agent layer 2 is stabilized for 10 minutes, apply the focus resin layer 4 on the surface of the photocuring agent layer 2;

[0026] Step 3: Sprinkle a single layer of glass beads 3 evenly on the surface of the focus resin layer 4 in step 2. The diameter of the glass beads 3 is 40 μm, and 1 / 3-1 / 2 of the glass beads 3 are embedded in the light-cured Agent layer 2, irradiated by ultraviolet lamp for 5 seconds;

[0027] Step 4: Apply a protective adhesive layer 5 to the surface of the glass microsphere 3 in step 3, the thic...

Embodiment 2

[0029] A kind of reflective luminous silk and preparation method thereof, such as figure 1 shown, including the following steps:

[0030] Step 1: Coat light curing agent layer 2 on PET film 1, the thickness of light curing agent layer 2 is 50 μ m, wherein the weight of polyester glue, diluent, adhesive agent, curing agent and fluorescent luminescent agent in light curing agent layer 2 The matching ratio is 5:1:2:2:3;

[0031] Step 2: After the photocuring agent layer 2 is stabilized for 30 minutes, apply the focus resin layer 4 on the surface of the photocuring agent layer 2;

[0032] Step 3: Sprinkle a single layer of glass beads 3 evenly on the surface of the focus resin layer 4 in step 2. The diameter of the glass beads 3 is 30 μm, and 1 / 3-1 / 2 of the glass beads 3 are embedded in the light curing Agent layer 2, irradiated by ultraviolet lamp for 60 seconds;

[0033] Step 4: Apply a protective adhesive layer 5 to the surface of the glass microbead 3 in step 3, the thickne...

Embodiment 3

[0036] A kind of reflective luminous silk and preparation method thereof, such as figure 1 shown, including the following steps:

[0037] Step 1: Coat light-curing agent layer 2 on PET film 1, the thickness of light-curing agent layer 2 is 30 μ m, wherein the weight of polyester glue, diluent, adhesive agent, curing agent and fluorescent luminescent agent in light-curing agent layer 2 The matching ratio is 5:1:2:2:3;

[0038] Step 2: After the photocuring agent layer 2 is stabilized for 60 minutes, apply the focus resin layer 4 on the surface of the photocuring agent layer 2;

[0039] Step 3: Sprinkle a single layer of glass beads 3 evenly on the surface of the focus resin layer 4 in step 2. The diameter of the glass beads 3 is 50 μm, and 1 / 3-1 / 2 of the glass beads 3 are embedded in the light-cured Agent layer 2, irradiated by ultraviolet lamp for 30 seconds;

[0040] Step 4: Apply a protective adhesive layer 5 to the surface of the glass microbead 3 in step 3, the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com