One glass solution (OGS) touch screen and fabrication process of OGS touch screen

A manufacturing process and touch screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of low yield, high cost, long processing cycle, etc., and achieve low cost, effective shading, Enhance the effect of shading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further elaborated below in conjunction with accompanying drawing:

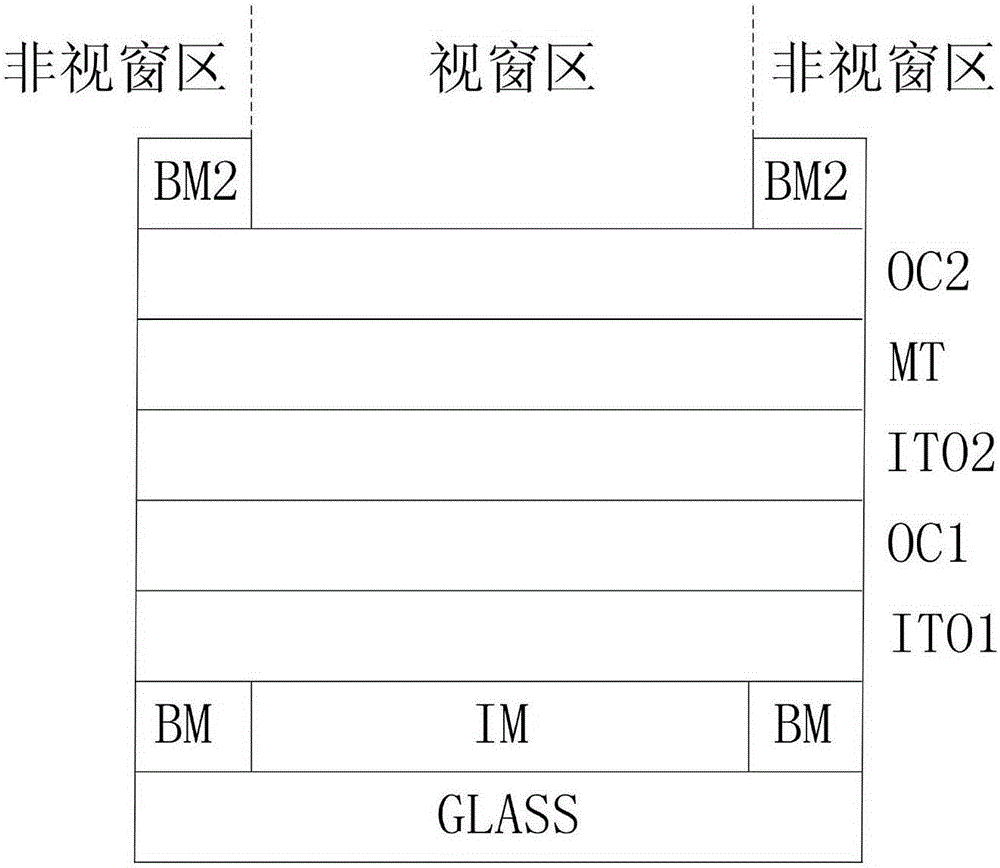

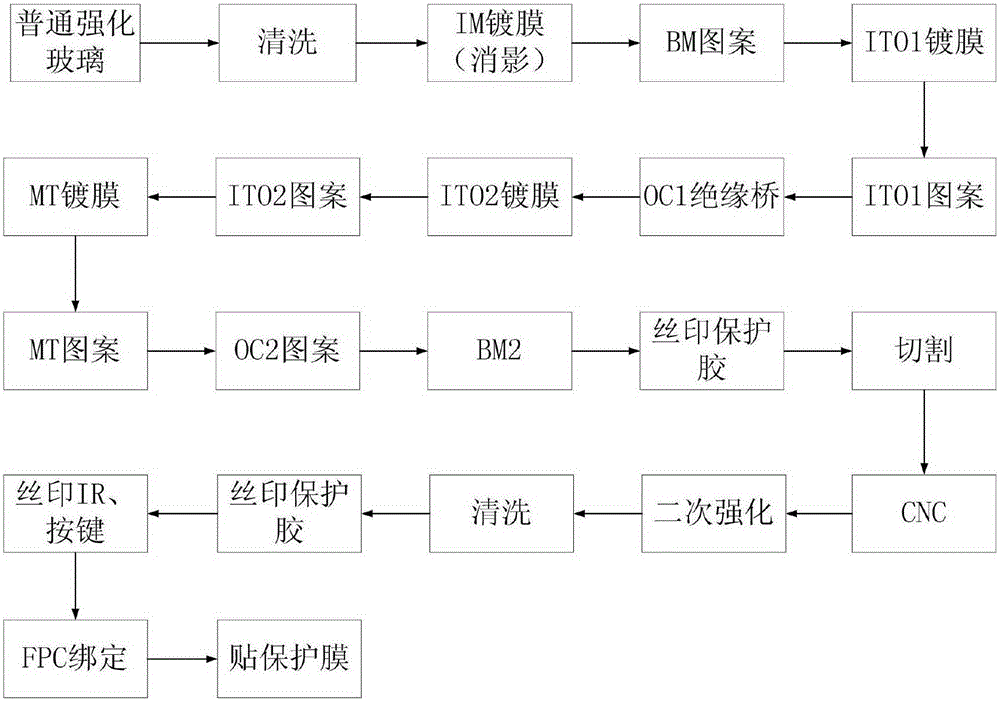

[0010] like figure 1 As shown, the OGS touch screen includes: strengthened glass GLASS, first primer ink BM, oxide film layer IM, first conductive layer ITO1, anti-short circuit insulating layer OC1 (insulation bridge), second conductive layer ITO2, connecting conductive layer MT, scratch-resistant insulating layer OC2, second primer ink BM2. The OGS touch screen has a windowed area and a non-windowed area. And the OGS touch screen is connected with the touch IC chip.

[0011] Strengthened glass GLASS is used as the base of the OGS touch screen. The first primer ink BM (BlackMatrix) is a black ink, which is set on the non-window area on the back of the strengthened glass GLASS, and has the characteristics of high covering, flatness, and insulation. It has two main functions: one is light-shielding, which prevents the X / Y electrode leads with strong reflectivity such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com