Support element for electric motor brush for fuel pump

A technology for supporting components and electric motors, which is applied in the direction of electric components, electrical components, circuits, etc., and can solve problems such as difficulty in component installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

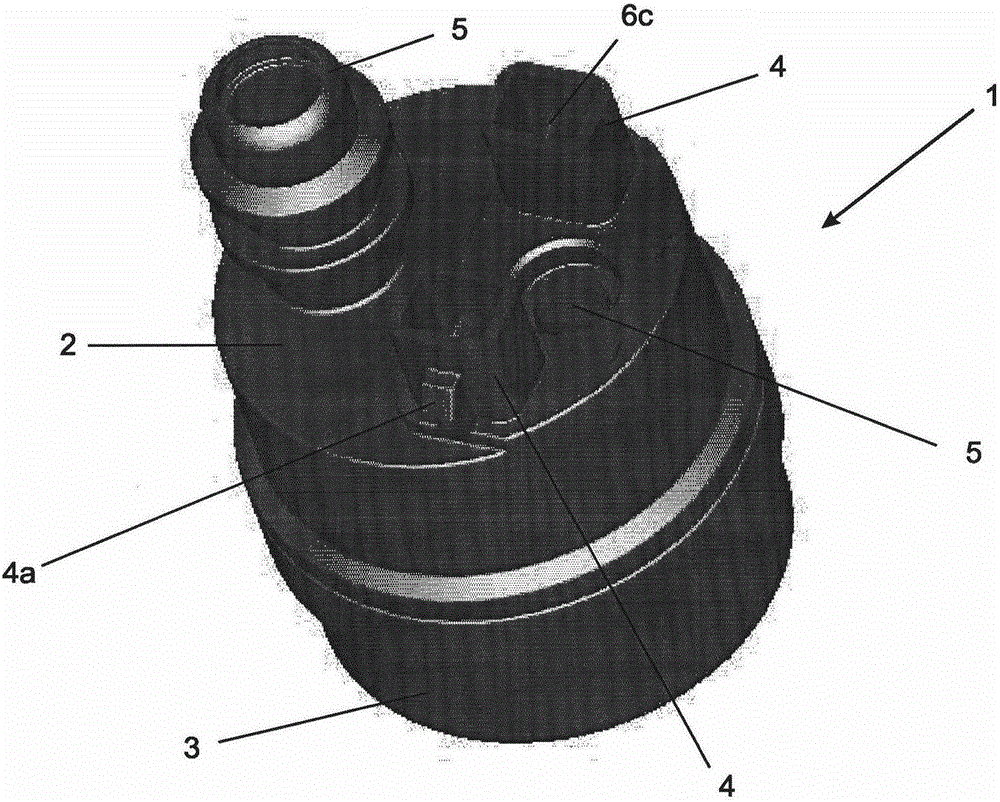

[0013] as can be obtained from figure 1 As seen in , the cover 2 is positioned on the body 3 of the fuel pump 1 . Cover 2 has an opening 5 for the flow of fuel pumped by fuel pump 1 . The cover 2 further has a female mating protrusion 4 to receive an electrical connector for feeding the electric motor of the pump 1 . The mating protrusions 4 surround the electrical contacts 6c to protect them from accidental contact, thereby reducing the effects of galvanic corrosion and ensuring food fixation of the electrical connector. The fitting protrusion 4 is provided with a snap-fit engaging part 4 a arranged on the side.

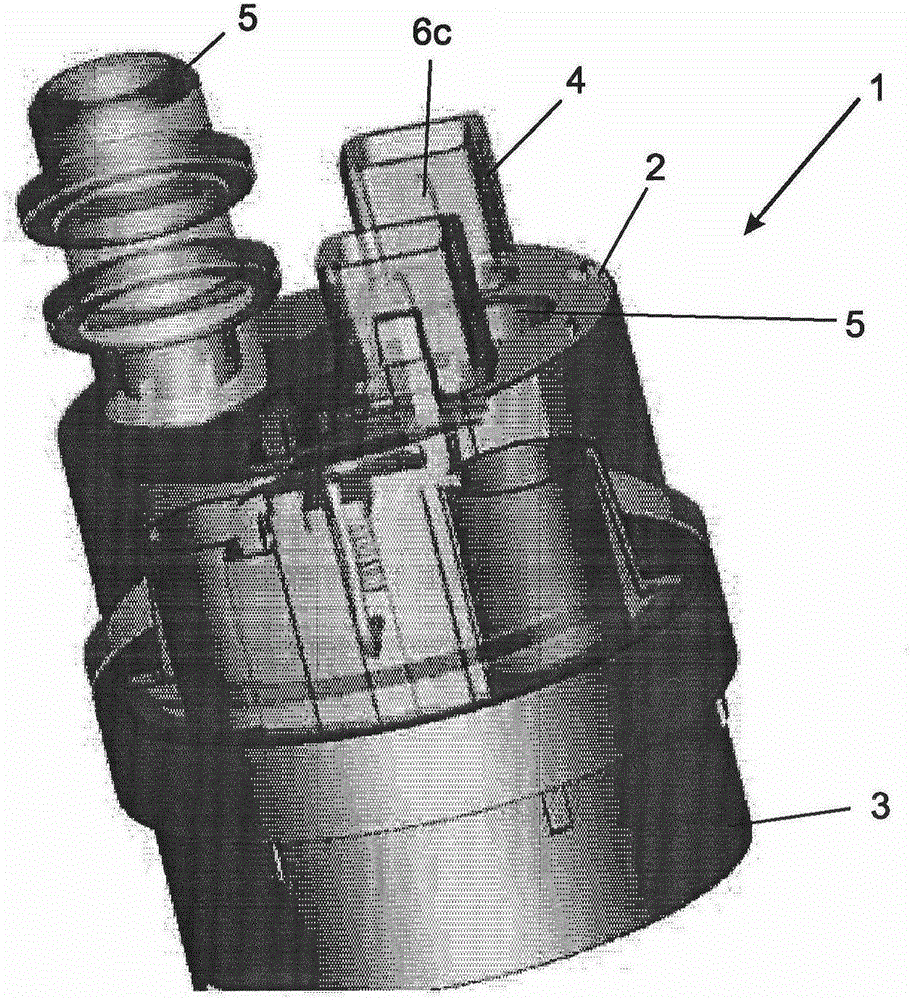

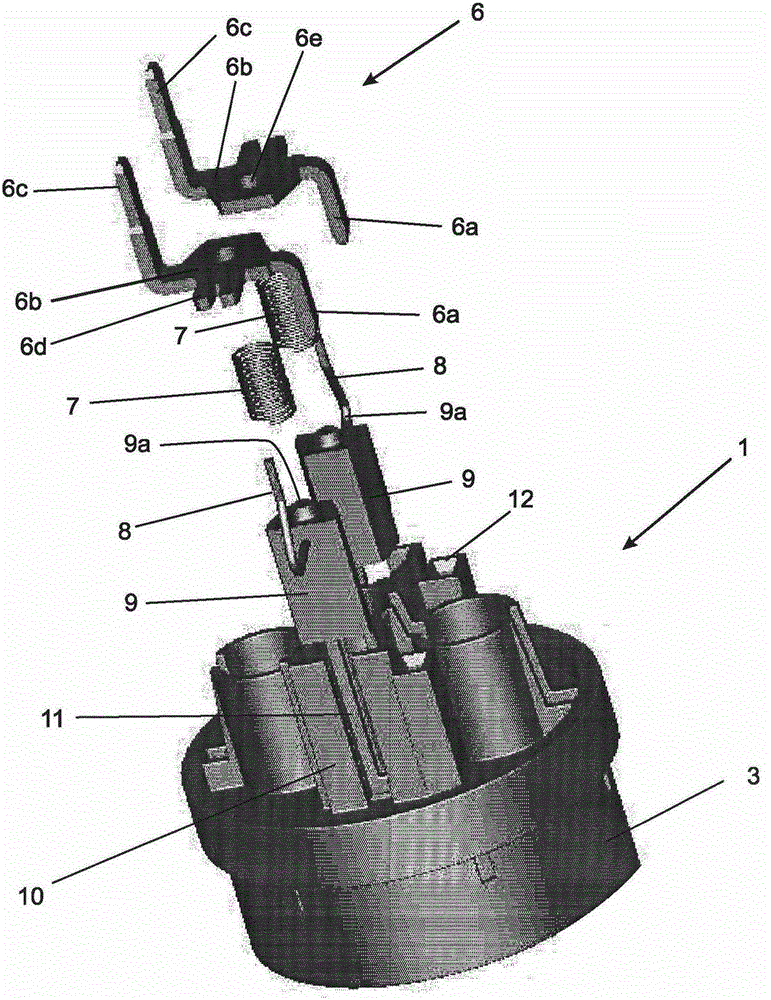

[0014] exist figure 2 In , the cover 2 of the fuel pump 1 is shown in perspective for easy observation of its internal parts. It can be seen that the electrical contact 6c is positioned within the female mating protrusion 4 . The opening 5 for the fuel flow and the brush holder 10 integrating the cover 2 with the pump body 3 can also be seen. image 3 The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com