Double reed automatic cutting and assembling machine

A technology of automatic cutting and double reed, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low installation efficiency, high scrap rate, low work efficiency, etc., to improve the pass rate, ensure production quality, and guarantee The effect of synchronicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

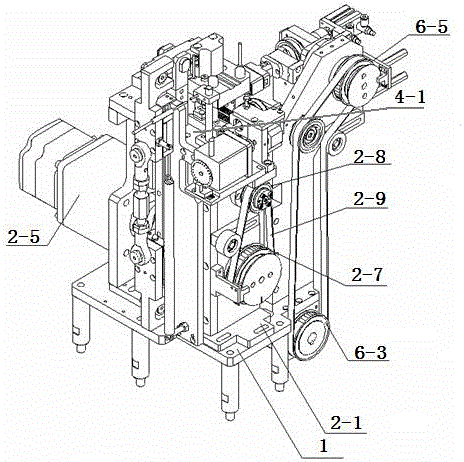

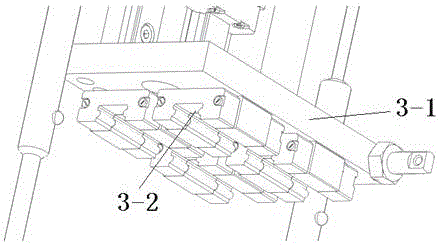

[0034] Example 1: Reference Figure 1-13 .

[0035] like figure 1As shown, the double reed automatic cutting and assembling machine includes a base plate 1, a transmission mechanism 2 is installed on the base plate 1, a front and rear transport mechanism 3 is installed on the transmission mechanism 2, and a mold punching material is arranged above the front and rear transport mechanism 3. Mechanism 4, one side of the transmission mechanism 2 is provided with a breaking part connection mechanism 5 that drives the movement of the mold punching mechanism 4, and the other side of the transmission mechanism 2 is equipped with a manipulator mechanism 6 that moves the workpiece. The mechanism 4 is provided with a feeding mechanism 7 for feeding it;

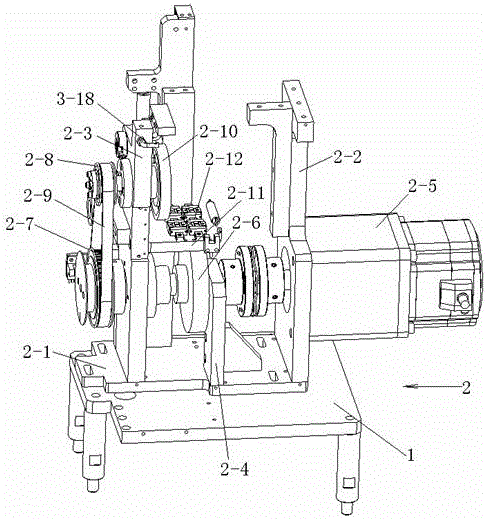

[0036] like figure 2 As shown, the transmission mechanism includes a cam lower fixed plate 2-1 installed on the bottom plate 1, and the two sides of the cam lower fixed plate 2-1 are provided with a vertical plate I2-2 and a vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com