Ceramic quartz paint and preparing process thereof

A preparation process and a technology for ceramics, applied in the field of ceramic quartz paint and its preparation process, can solve the problems of acid and alkali resistance chemical properties that are difficult to meet high standards, returning to alkali, affecting the service life of buildings, etc.

Inactive Publication Date: 2016-01-20

CHONGQING FORCE HAO COLOR BUILDING MATERIALS CO LTD

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In terms of the current architectural exterior wall coating products and decorative effects, common exterior wall decorative coatings are prone to alkali return and surface blooming due to various construction conditions and methods. The chemical properties are difficult to meet the requirements of high standards, and under the repeated action of natural conditions, the coating is prone to cracking, powdering, peeling, discoloration and other phenomena, which makes the coating lose its original decorative protection, thus affecting the building. Service life, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

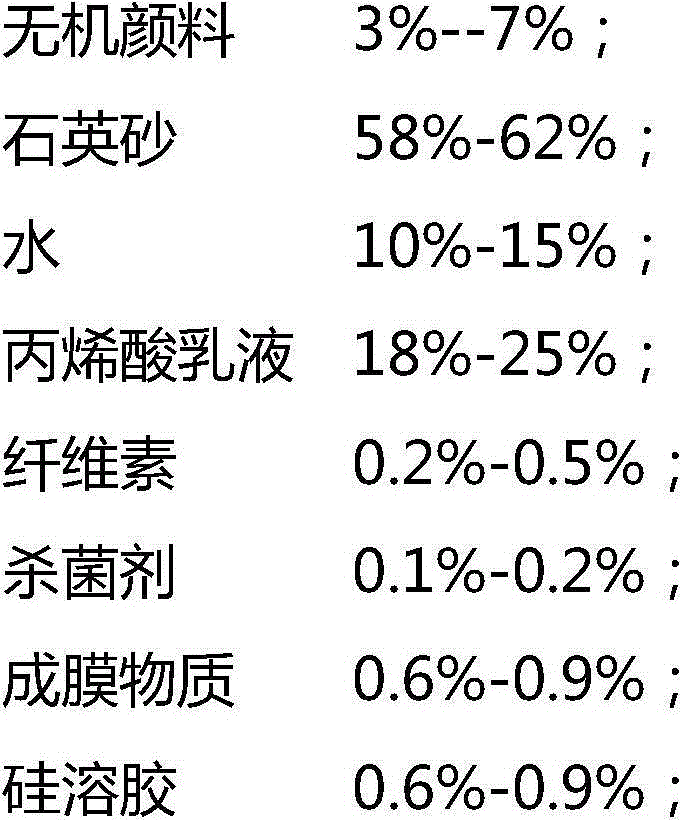

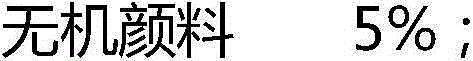

The invention discloses ceramic quartz paint. The ceramic quartz paint is prepared from, by weight, 3-7% of inorganic pigment, 58-62% of quartz sand, 10-15% of water, 18-25% of acrylic emulsion, 0.2-0.5% of cellulose, 0.1-0.2% of bactericide, 0.6-0.9% of film forming matter and 0.6-0.9% of silica sol, and the total percentage of the components is 100%. The invention also provides a preparing process of the ceramic quartz paint. According to the preparing process, raw materials are matched according to a scientific and refined ratio for production, and regulation is conducted for each step in strict accordance with technical requirements, so that the optimum state of a product is guaranteed. The environment-friendly, healthy and pollution-free principle is followed during production, environment friendliness of the preparing process is guaranteed, and the national policy requirement for green building materials is met.

Description

technical field [0001] The invention relates to a ceramic quartz varnish and a preparation process thereof, belonging to the field of architectural decoration. Background technique [0002] In terms of the current architectural exterior wall coating products and decorative effects, common exterior wall decorative coatings are prone to alkali return and surface blooming due to various construction conditions and methods. The chemical properties are difficult to meet the requirements of high standards, and under the repeated action of natural conditions, the coating is prone to cracking, powdering, peeling, discoloration and other phenomena, which makes the coating lose its original decorative protection, thus affecting the building. service life etc. Contents of the invention [0003] The purpose of the present invention is to solve the above problems and provide a kind of ceramic quartz paint, which aims to implement the concept of national green building more efficiently...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D133/00C09D7/12

Inventor 李治伟徐念杨康乐

Owner CHONGQING FORCE HAO COLOR BUILDING MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com