A method for extracting rubidium and cesium from acid brine

A rubidium-cesium and brine technology, applied in the field of salt lake chemistry and chemical industry, can solve problems such as unreported technical solutions, lack of brine pretreatment process, great adsorption and separation interference, etc., achieving low production cost, easy solid-liquid separation, The effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

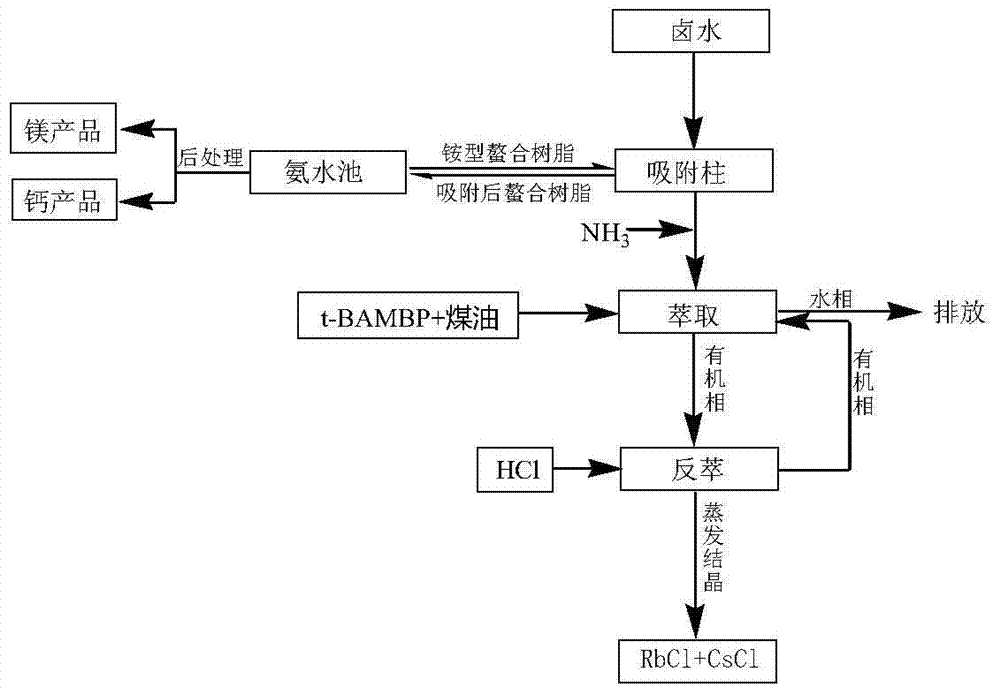

[0028] see figure 1 , at 25°C, the initial concentrations of rubidium, cesium, sodium, potassium, calcium, and magnesium ions in brine were 19.0mg / L, 2.0mg / L, 30.55g / L, 20.60g / L, 23.84g / L, and 28.38 g / L, take 50g of ammonium-type chelating resin and pack it into the column, pump 100mL of simulated brine into the adsorption column, and transfer it to the ammonia water pool for transformation after the resin is saturated, wash away the residual ammonia on the surface and reload it into the adsorption column, and wait for After removing calcium and magnesium, add ammonia water to make the pH of the effluent to 11, then mix with 100mL 1mol / L t-BAMBP sulfonated kerosene solution and enter the extraction device to vibrate for 10min, after standing for 5min, the oil and water are separated, and the water phase is discharged for subsequent salt extraction treatment , the organic phase enters the stripping device, add 80mL of 2.0mol / L HCl to shake for 10min, let stand for 5min to separ...

Embodiment 2

[0030] At 25°C, the initial concentrations of rubidium, cesium, sodium, potassium, calcium, and magnesium ions in brine are 19.0mg / L, 2.0mg / L, 30.55g / L, 20.60g / L, 23.84g / L, and 28.38g, respectively / L, take 50g of ammonium-type chelating resin and pack it into the column, pump 100mL of simulated brine into the adsorption column, transfer it to the ammonia water pool for transformation after the resin is saturated, wash off the residual ammonia on the surface and reload it into the adsorption column, wait for the calcium After removing magnesium, add ammonia water to make the pH of the effluent liquid 11, then mix it with 100mL 1mol / L t-BAMBP sulfonated kerosene solution and enter the extraction device to vibrate for 5 minutes, after standing for 5 minutes, the oil and water are separated, and the water phase is discharged for subsequent salt extraction treatment. The organic phase enters the stripping device, add 80mL of 2.0mol / L HCl to shake for 10min, stand still for 5min to ...

Embodiment 3

[0032] At 25°C, the initial concentrations of rubidium, cesium, sodium, potassium, calcium, and magnesium ions in brine are 19.0mg / L, 2.0mg / L, 30.55g / L, 20.60g / L, 23.84g / L, and 28.38g, respectively / L, take 50g of ammonium-type chelating resin and pack it into the column, pump 100mL of simulated brine into the adsorption column, transfer it to the ammonia water pool for transformation after the resin is saturated, wash off the residual ammonia on the surface and reload it into the adsorption column, wait for the calcium After removing magnesium, add ammonia water to make the pH of the effluent liquid 11, then mix it with 100mL 1mol / L t-BAMBP sulfonated kerosene solution and enter the extraction device to vibrate for 10 minutes, after standing for 5 minutes, the oil and water are separated, and the water phase is discharged for subsequent salt extraction treatment. The organic phase enters the stripping device, add 80mL of 2.0mol / L HCl to shake for 5min, let stand for 5min to se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com