Natural pure cotton crease-resistant finishing agent

An anti-wrinkle finishing agent, a natural technology, applied in fiber treatment, textiles and papermaking, etc., can solve the problems of finishing fabric strength loss, poor high temperature resistance stability, low reactivity, etc., achieve good stability, good compatibility, and source rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

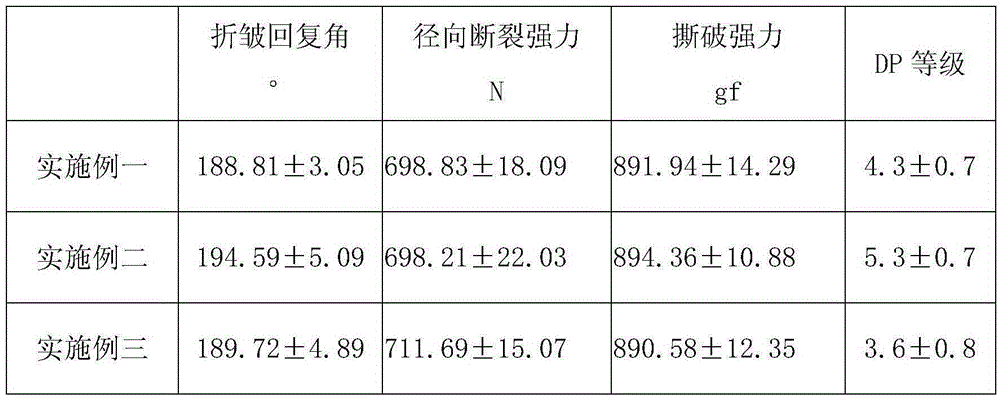

[0026] The natural pure cotton anti-wrinkle finishing agent of the present invention comprises the following components in parts by weight, see Table 1, and the unit is parts by weight.

[0027] Table 1: Components of natural pure cotton anti-wrinkle finishing agent (unit: parts by weight)

[0028]

Peanut Leaf Extract

buckwheat extract

Corn Silk Extract

Embodiment one

2

3

2

0.7

Embodiment two

4

7

5

1.2

Embodiment three

2.5

4

2.5

0.8

Embodiment Four

4

6

4.5

1.0

Embodiment five

2

7

2

1.2

Embodiment six

4

3

5

0.7

[0029] Embodiment seven

2.5

6

3

1.0

Embodiment eight

3

5.5

3.5

1.1

Embodiment nine

3.5

5

4

1.2

Embodiment ten

3.5

5

3

0.9

control group one

1

0

0

0

Control group two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com