Electric mechanical barring for water turbine

A technology of mechanical discs and water turbines, which is applied in the direction of machines/engines, hydroelectric power generation, mechanical equipment, etc. It can solve the problems of cranking vibration, high installation costs of multiple motors and reducers, and achieve amplified torque, compact structure, and high power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

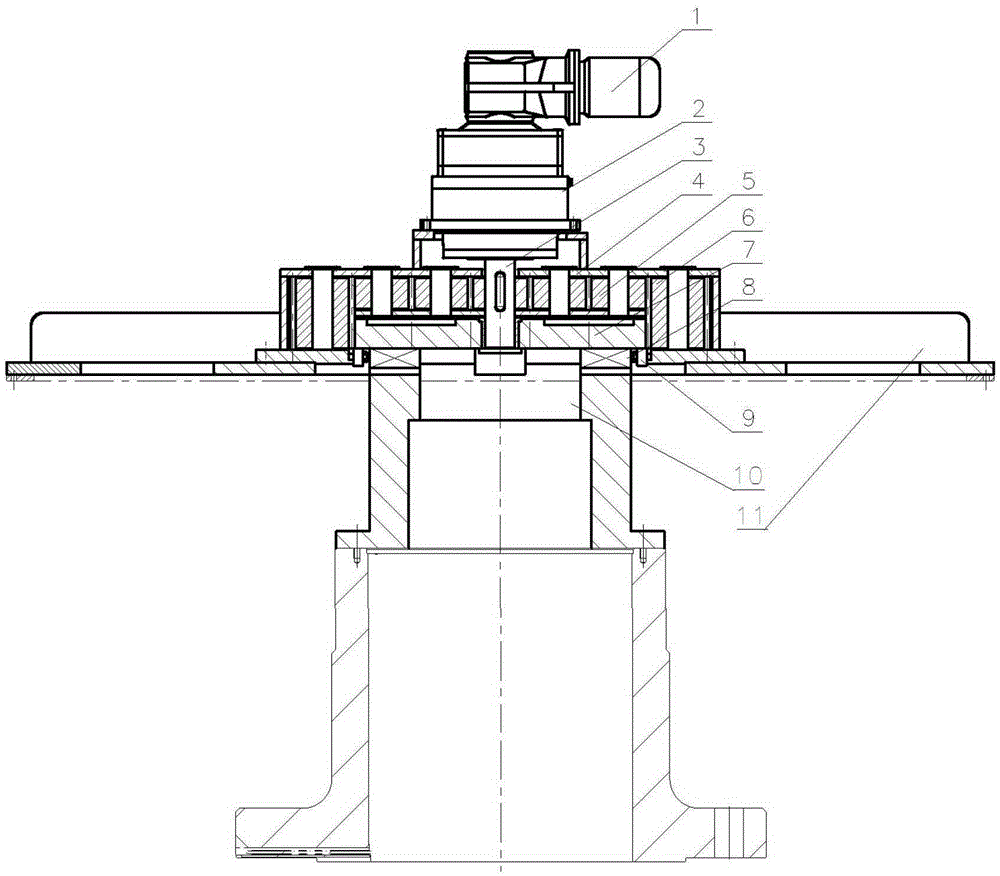

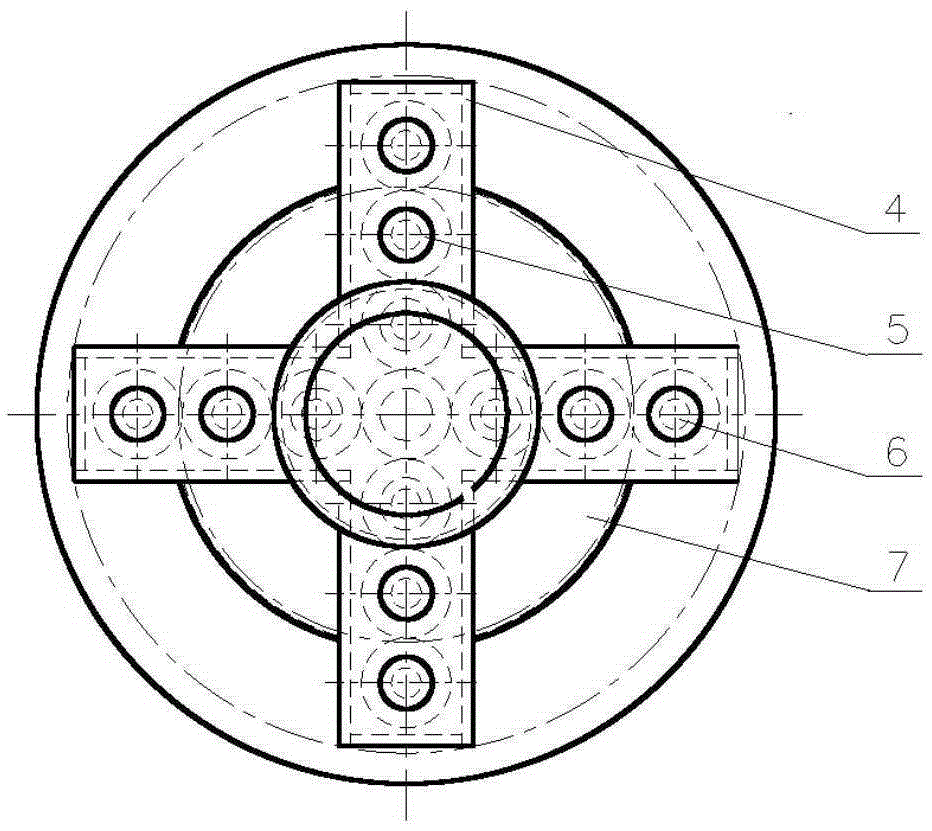

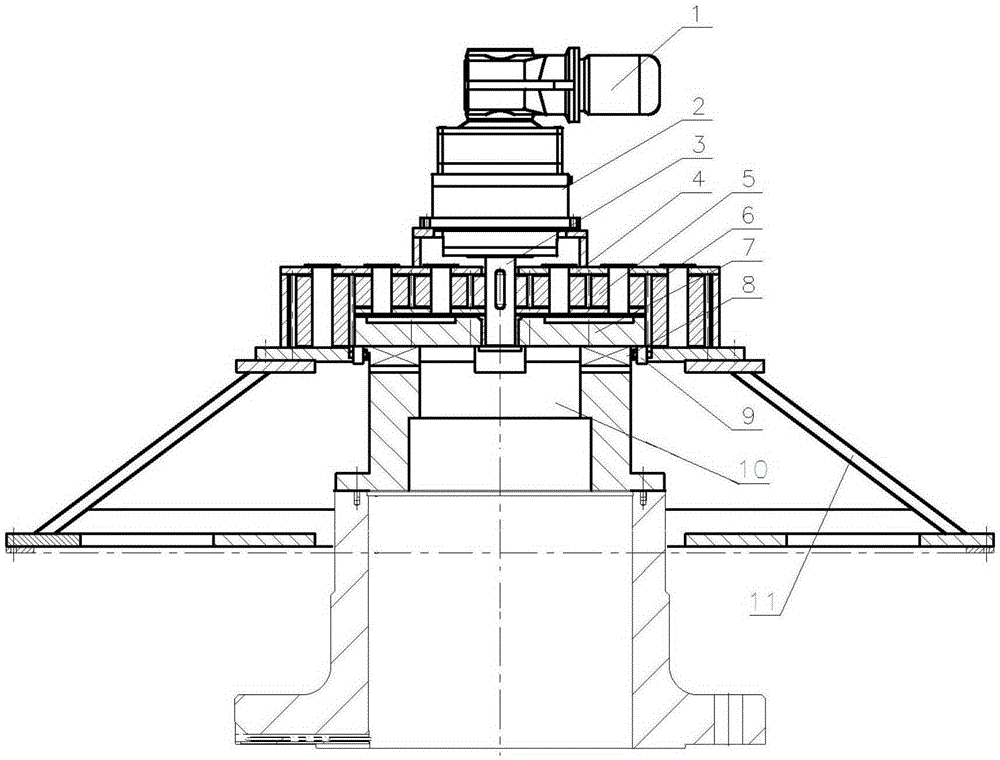

[0040] As above-mentioned mechanical barring, the present embodiment differs from it in that, as figure 2 As shown in the top view of the electromechanical barring of the water turbine of the present invention without the speed reducer, the central gear, the transmission gear 5 and the double gear 6 have the same number of teeth, so that the central gear, the transmission gear 5 and the Only transmission is carried out between the dual gears 6, which plays a simple transmission role, does not change the rotating speed, and its rotating speed is constant; the outer diameter and the number of teeth of the said disc gear 7 are greater than the outer diameter and the number of teeth of the said dual gears 6, In this way, the double gear 6 meshes with the disk gear 7, which not only plays a transmission role, but also increases the transmission ratio. The large gear 7 is decelerated and the disk torque is increased, so that the transmission force is greater.

Embodiment 2

[0042] As above-mentioned mechanical barring, the present embodiment differs from it in that, as figure 2 As shown in the top view of the water turbine of the present invention with electromechanical barring without the reducer, the gear sets are radially evenly divided relative to the chassis, and the included angle between two adjacent groups is 360 / N degrees, so that the output is even.

[0043] Central gear and disk gear 7 have only one.

[0044] A gear set includes at least one transmission gear 5 and a dual gear 6, the dual gear 6 is located at the outermost side of the transmission gear 5, and the number of transmission gears 5 is at least one, which can also be 2, 3, or 4 , 5, 6, 7, 8 or more, the quantity of transmission gear 5 is mainly determined by the weight of the turbine generator shaft and the size of the shaft.

[0045] The number of transmission gears 5 in one gear set is preferably 2-8.

Embodiment 3

[0047] As mentioned above, the electromechanical barring of the water turbine, the difference of this embodiment is that the disc gear 7 and the connecting cylinder or the connecting plate 10 are clamped together through the meshing mechanism 8, and the meshing mechanism 8 includes a A set of protrusions and a set of corresponding grooves; the cross sections of the protrusions and grooves can be square, circular, or other shapes. The wheel surface of the disc gear 7 is provided with the protrusions or grooves, and the connecting cylinder or the connection plate 10 is provided with the grooves or protrusions; the protrusions are inserted into the grooves and locked, and when clamped There is a gap between the protrusion and the groove, and they are not in contact.

[0048] The purpose of barring is to verify whether the turbine shaft and generator shaft are installed in the center position. If the turbine shaft and generator shaft are installed in the center position, there wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com