A type of elliptical tooth profile rotor oil pump, its rotor and rotor design method

A kind of ellipse and tooth profile technology, applied in mechanical equipment, rotary piston pumps, rotary piston machines, etc., to reduce wear and energy consumption, improve wear, and reduce modification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

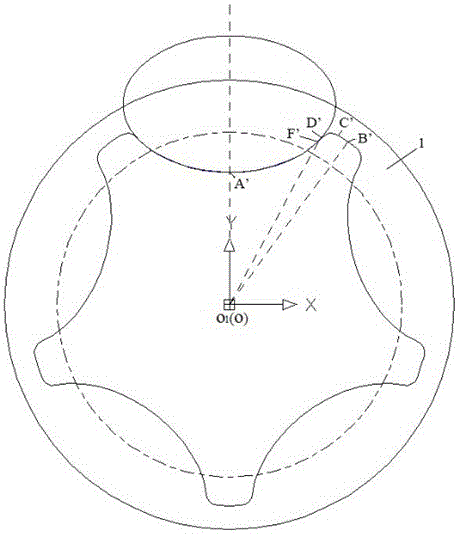

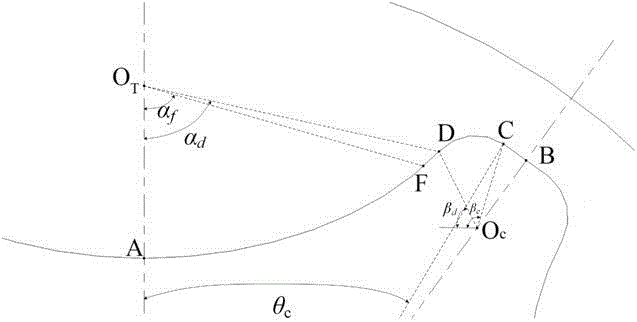

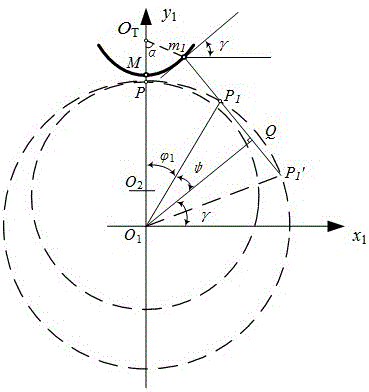

[0060] Such as Figure 2-5 As shown, a design method for a similar elliptical tooth profile rotor includes the following steps:

[0061] Step (1), determining the ellipse-like theoretical tooth profile of the outer rotor;

[0062] Take one tooth profile center O of an elliptical outer rotor with the same basic design parameters T is the tooth profile center of the quasi-elliptic outer rotor, constructing its theoretical tooth profile; in the outer rotor center O 1 As the center of the circle, the Cartesian coordinate system O fixed on the outer rotor 1 -(x 1 ,y 1 ), the tooth profile equation of the quasi-elliptic outer rotor is:

[0063]

[0064] In formula (1), x 1 , is the tooth profile abscissa of the quasi-elliptic outer rotor, y 1 is the ordinate of the tooth profile of the quasi-elliptic outer rotor; b is the length of the minor semi-axis of the original elliptical tooth profile; R 1 is the tooth profile center O T to the outer rotor center O 1 distance; α ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com