Damping spring

A shock-absorbing spring and three-dimensional shock-absorbing technology, applied in the field of mechanical parts, can solve the problems of limited use conditions, large space occupation, and high cost, and achieve the effects of easy standardized production, convenient installation and replacement, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

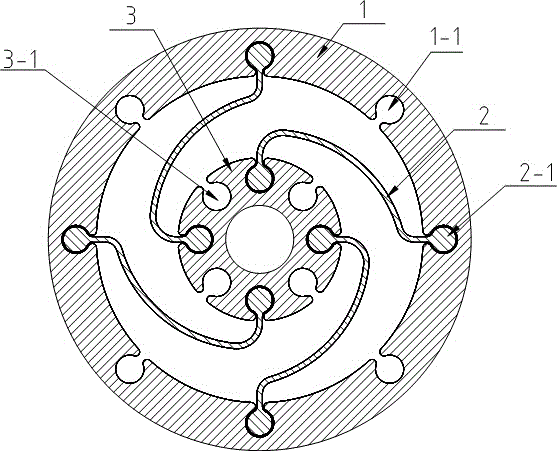

[0025] refer to figure 1 As shown, this embodiment is a two-dimensional damping spring with a split structure, including a spring outer casing 1, four spring monomers 2, and a spring inner sleeve 3. The spring monomer 2 is located in the spring and between the outer casing, and the spring The two ends of the monomer 2 are respectively misplaced and connected to the outside of the spring inner sleeve 3 and the inner side of the spring outer sleeve 1. The two ends of the spring inner sleeve and the outer sleeve are respectively provided with closed rings (not shown in the figure), and the closed rings are connected with the spring inner sleeve and the spring outer sleeve. They are fixed by threaded connections to maintain the stability of the installation position of the spring unit 2.

[0026] Specifically, the spring jacket 1, the spring monomer 2 and the spring inner sleeve 3 are formed respectively, the spring monomer 2 is a curved plate-like structure, and cylinders 2-1 are...

Embodiment 2

[0032] The spring outer casing 1, the spring monomer 2, and the spring inner casing 3 are directly poured into an integral part. Select different types of surface or curve spring monomers according to the requirements of use. When the spring monomer adopts a curved plate-like structure, it constitutes a two-dimensional damping spring; when the spring monomer adopts a curved spring, it constitutes a three-dimensional damping spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com