Hand-cranked command workbench lifting device

A workbench and hand-operated technology, applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problems of inconvenient and fast moving, heavy weight, etc., and achieve the effect of coordinated movement, small space occupation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

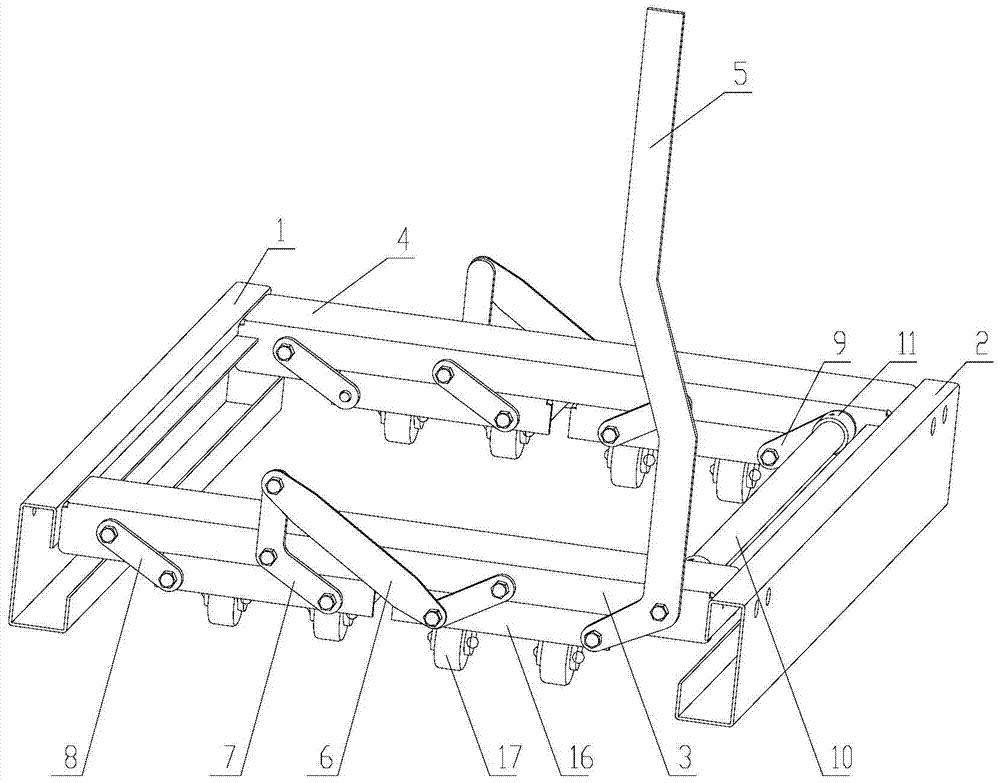

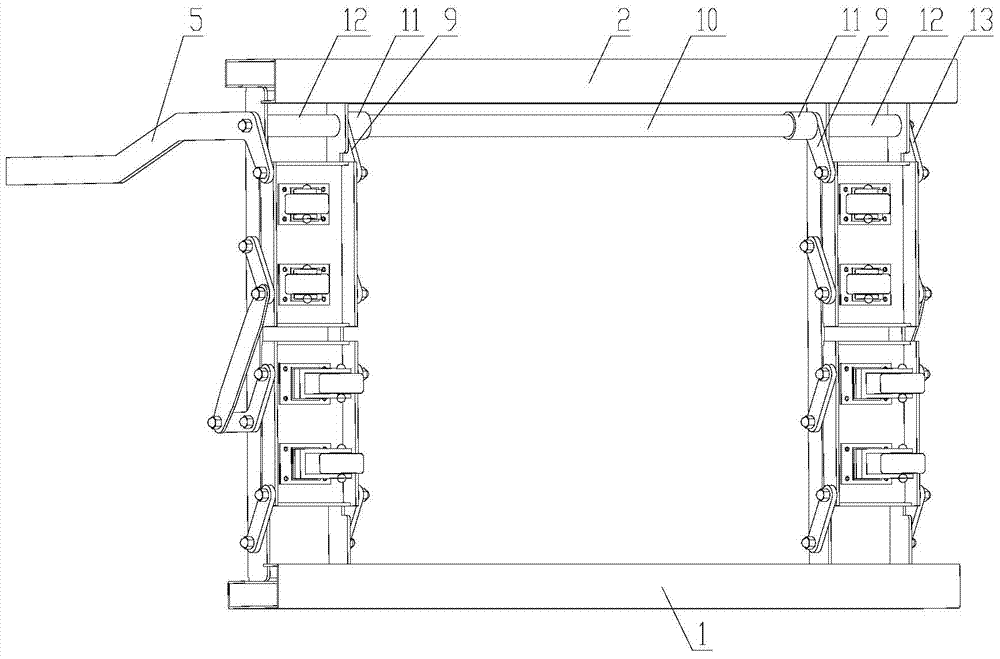

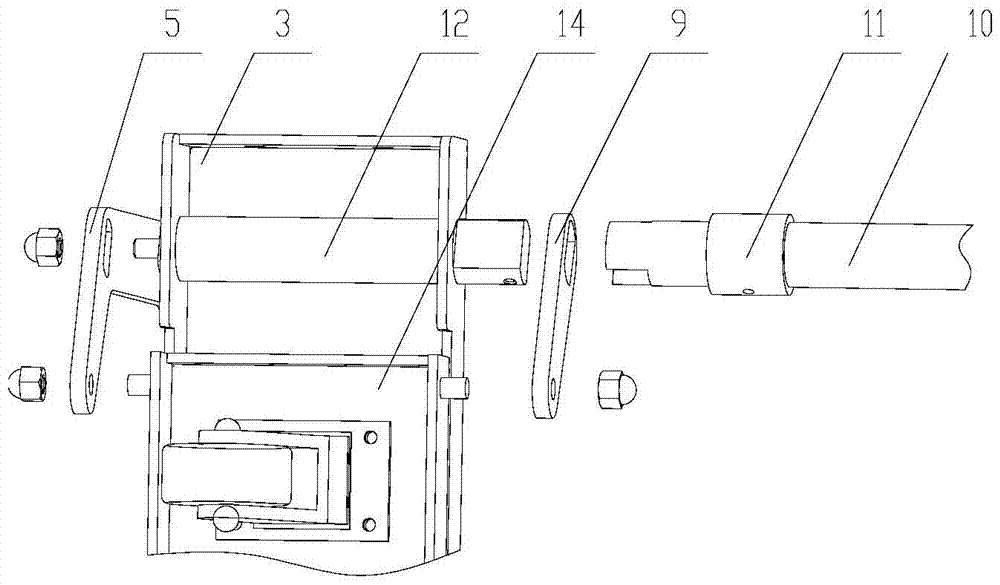

[0018] combine figure 1 , a hand-operated command workbench lifting device of the present invention, including a frame, a transmission device and 2N bottom wheel assemblies, N≥2; the frame includes a front frame 1, a rear frame 2, a left frame 3 and a right frame 4. Each bottom wheel assembly includes a bottom wheel seat 14 and a bottom wheel 15. The transmission device includes a crank handle 5, a connecting rod and a long shaft 10; 2N bottom wheel seats are respectively connected to the left frame 3 and the right frame through the connecting rod 4 are connected to form 2N four-bar linkage mechanisms, wherein the four-bar linkage mechanism connected to the rocker 5 is connected to the four-bar linkage mechanism on the opposite side frame through the long axis 10, so as to realize the coordinated operation of the 2N four-bar linkage mechanisms.

[0019] Further, when N is 2, that is, the number of bottom wheel assemblies is 4, the transmission device includes crank handle 5, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com