Lightweight RF Connectors

A radio frequency connector, light-weight technology, applied in the direction of connection, two-part connection device, electrical components, etc., can solve problems such as unsatisfactory, small distance between low-profile antenna unit and reflector, and connector without strength performance, etc., to achieve reduction Effects of chain breaking, increased strength, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

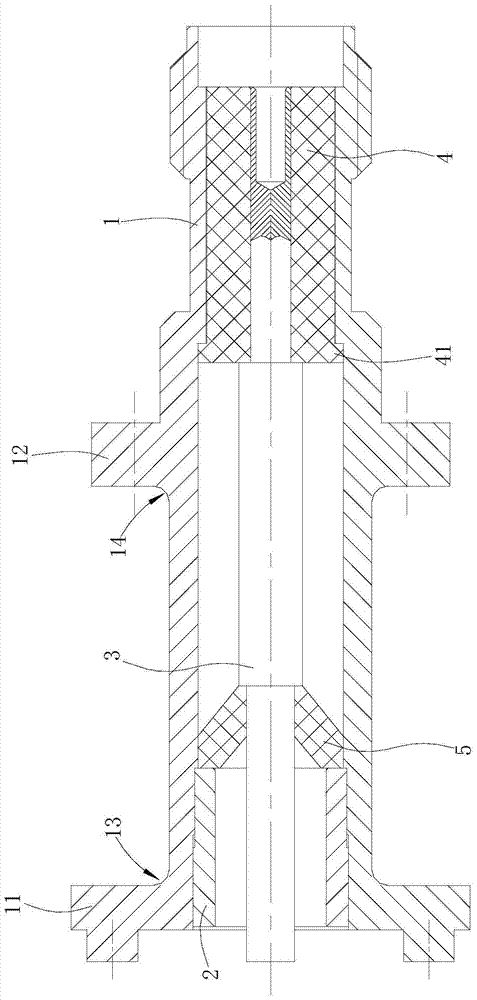

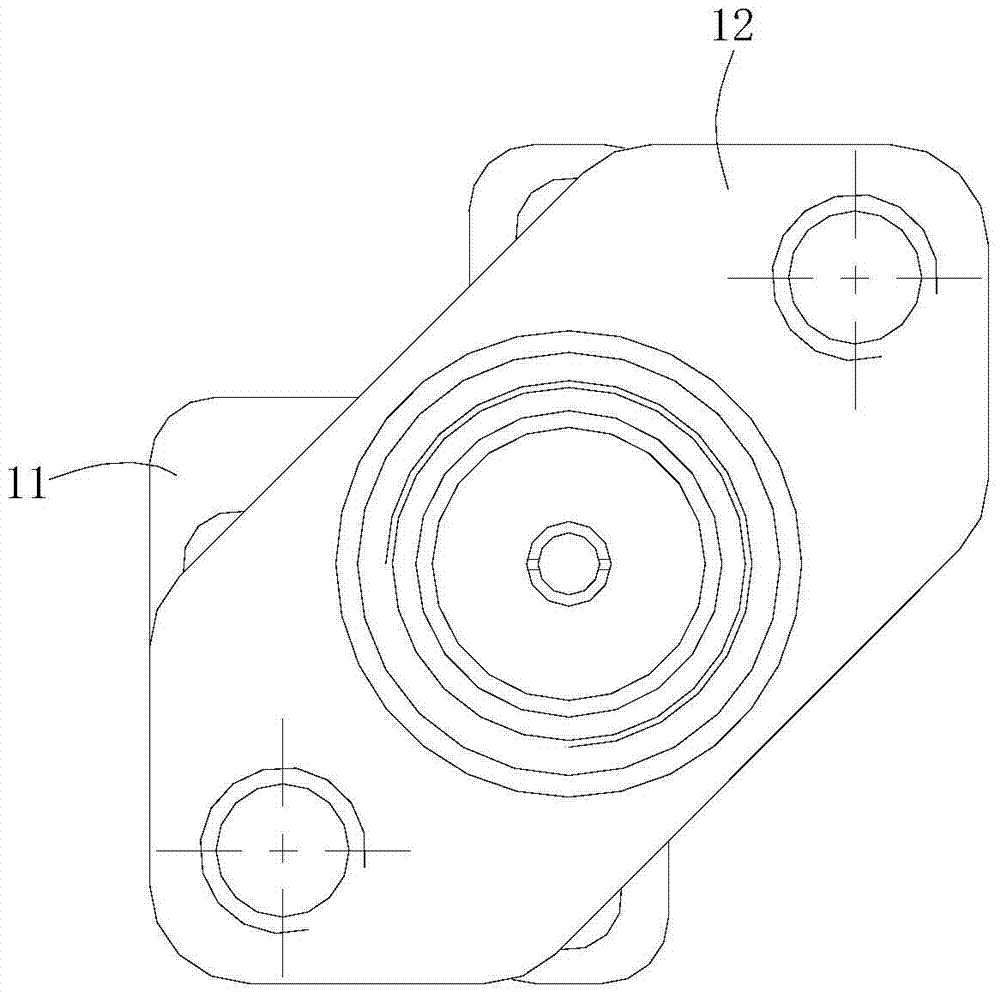

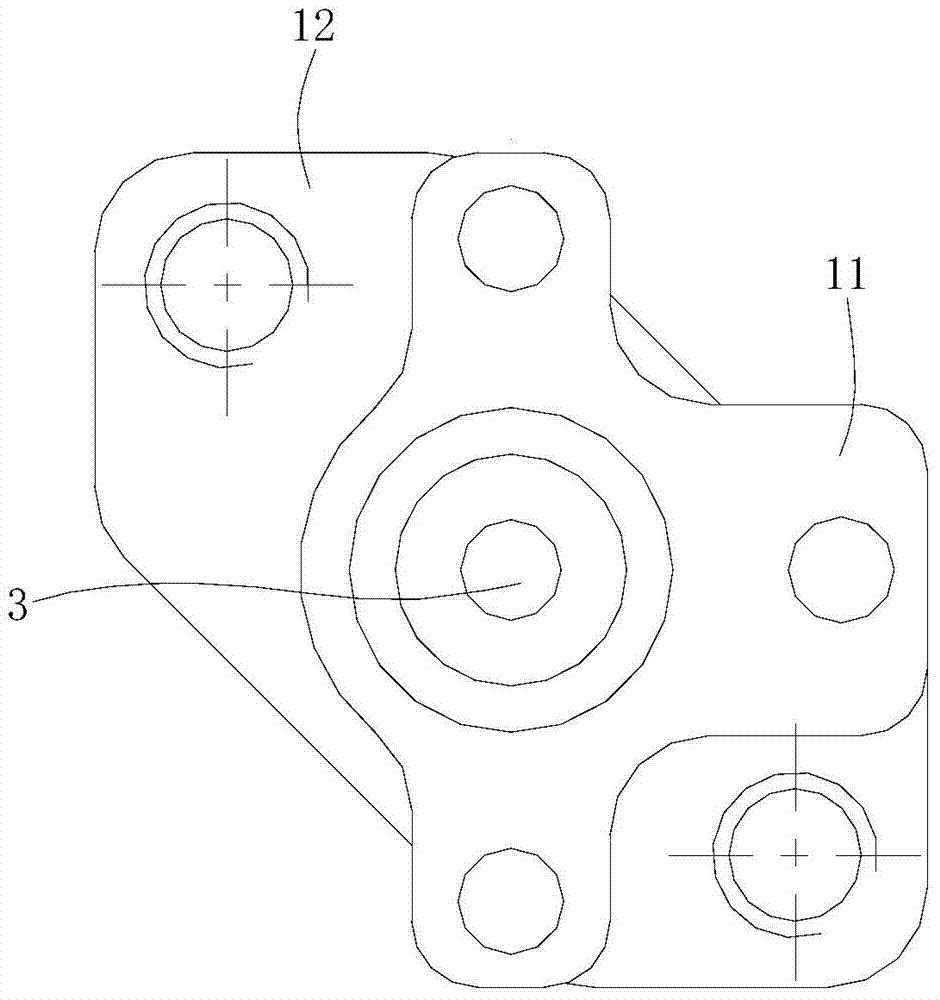

[0022] like Figures 1 to 5 shown

[0023] The lightweight radio frequency connector includes an inner conductor 3, a shell 1, a pressing sleeve 2 and two insulating sleeves.

[0024] The shell 1 is in the shape of a straight tube, the rear end of the outer wall of the shell 1 extends outwards with a first flange 11, the first flange 11 is a special-shaped flange, and a process fillet 13 is provided between the front end of the first flange 11 and the outer wall of the shell 1 There is a second flange 12 extending outward from the middle of the outer wall of the housing 1, and a process fillet 14 is also provided between the rear end surface of the second flange 12 and the outer wall of the housing 1. The second flange 12 is a diamond-shaped flange with two holes. The distance from the flange 12 to the rear end of the housing 1 is assumed to be L, the distance of L is 80mm, the length of the housing 1 is assumed to be H, and the length of H is 146mm, satisfying the following ...

Embodiment 2

[0041] The difference between this embodiment and the first embodiment is only that the distance of L can be 90mm, the length of H can be 140mm, and L:H=4.5:7.0.

Embodiment 3

[0043] The difference between this embodiment and the first embodiment is only that the distance of L can be 84mm, the length of H can be 144mm, and L:H=4.2:7.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com