A high-voltage connector

A technology of high-voltage connectors and connecting seats, which is applied in the direction of connection, installation of connection parts, and parts of connection devices, etc. It can solve problems such as high single-circuit working voltage, easy shrinkage of materials, and difficulty in meeting withstand voltage requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

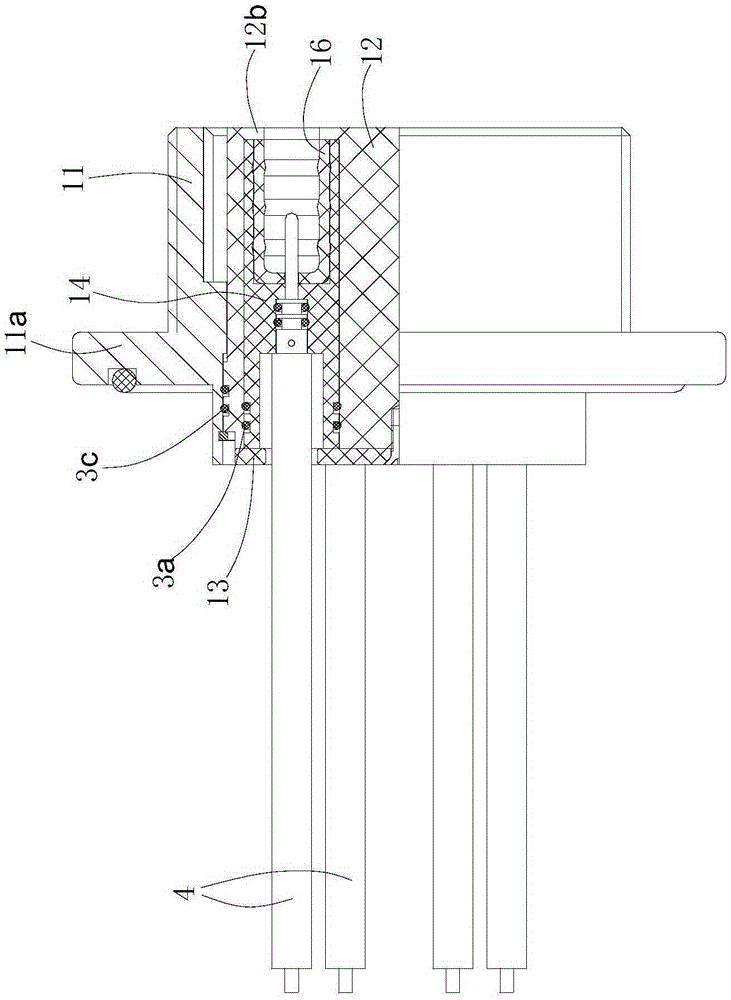

[0032] like Figures 1 to 7 shown

[0033] This high voltage connector consists of a plug and a socket.

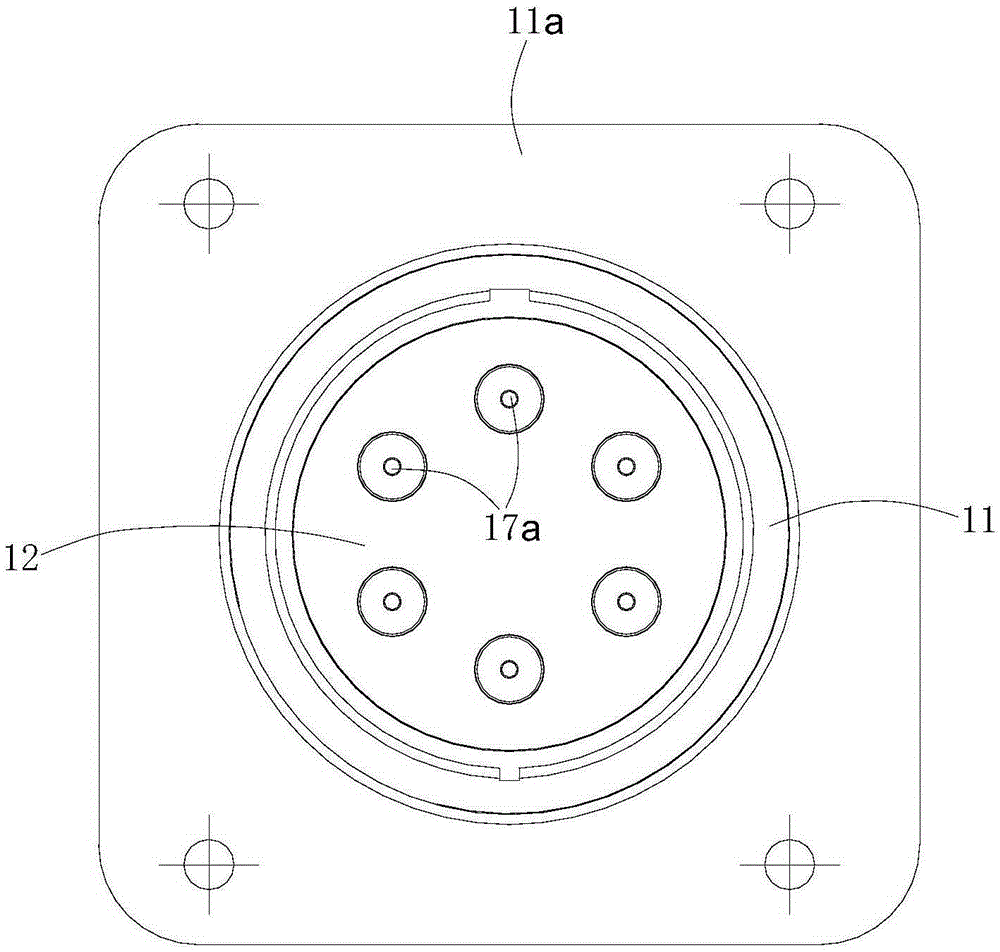

[0034] The socket includes a socket housing 11, a socket mounting plate 12, a socket pressing plate 13, a sealing sleeve 16, six groups of pin assemblies, six socket insulating sleeves 14 and a plurality of sealing rings.

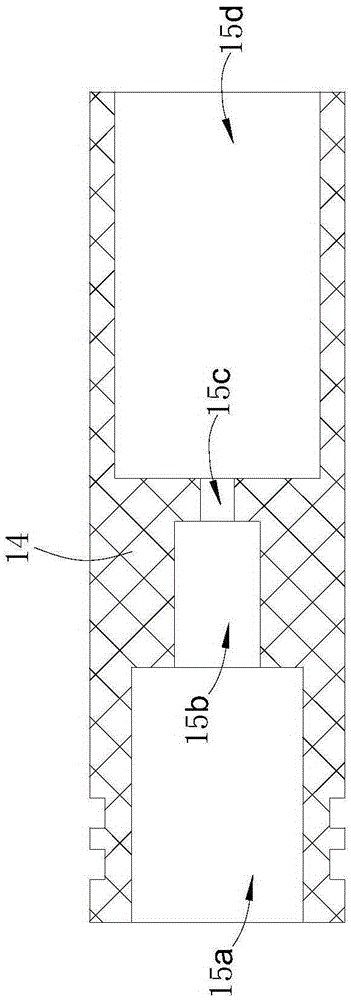

[0035] The socket mounting plate 12 is set in the socket housing 11. The rear part of the socket housing 11 is provided with external threads, and the outer side of the middle part of the socket housing 11 is provided with a flange 11a. Two third sealing rings 3c are provided, the rear end face of the socket mounting plate 12 is a plane, and the socket mounting plate 12 has six first mounting holes (not shown in the figure), and the first mounting holes run through the socket mounting plate 12 On the front and rear end faces, the front end of the first installation hole wall extends inwardly with an inner convex ring 12b, the front side of the socket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com