Plasma generator

A plasma and generator technology, applied in the field of plasma generators, can solve problems such as the failure of the plasma generator to work normally, potential safety hazards of the circuit, poor resistance to high voltage and breakdown resistance of the wires, etc., and achieve a simple structure and not easy to short circuit , high pressure resistance and breakdown resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

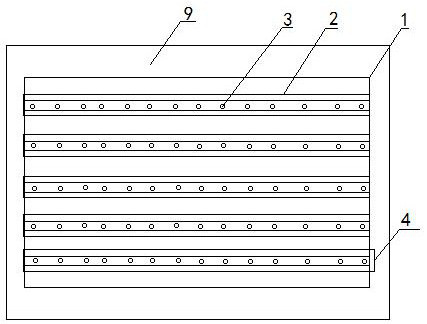

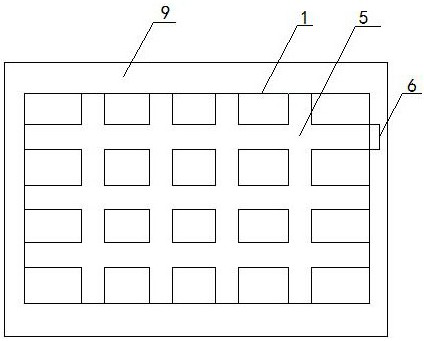

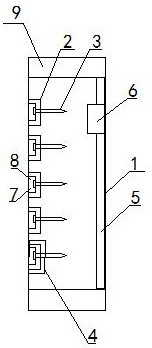

[0013] according to Figures 1 to 4 As shown, the present invention relates to a plasma generator, which includes a hollow cuboid frame 1, and the inside of the front of the frame 1 is provided with a plurality of insulating plates 2 with accommodating grooves 7 in parallel, each of the insulating plates 2 A number of high-voltage emitting needles 3 passing through the insulating plate 2 are arranged at intervals in the containing groove 7, and the containing groove 7 of each insulating plate 2 is filled with carbon film paper electrically connected to the high-voltage emitting needle 3 8, and the carbon film paper 8 in the accommodation groove 7 of each of the insulating plates 2 is connected in parallel, and the side wall of the frame 1 is provided with a positive plate 4 electrically connected to the carbon film paper 8 in each of the accommodation grooves 7, The rear inner side of the frame 1 is provided with a grid plate 5, and the side wall of the frame 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com