Mounting structure of photovoltaic power generation system

A technology of photovoltaic power generation system and installation structure, applied in photovoltaic power generation, support structure of photovoltaic modules, photovoltaic modules, etc., can solve the problems of one-way connection, complex structure of connectors, low reliability, etc., to improve installation efficiency, The effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

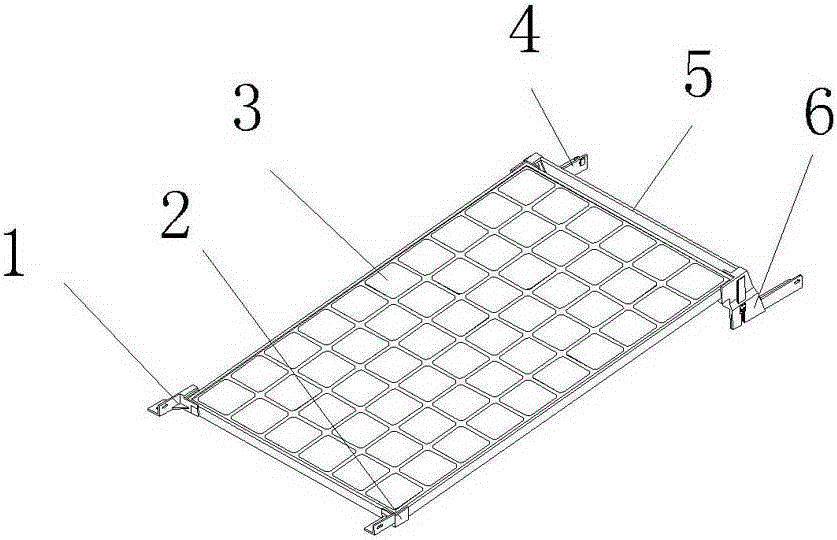

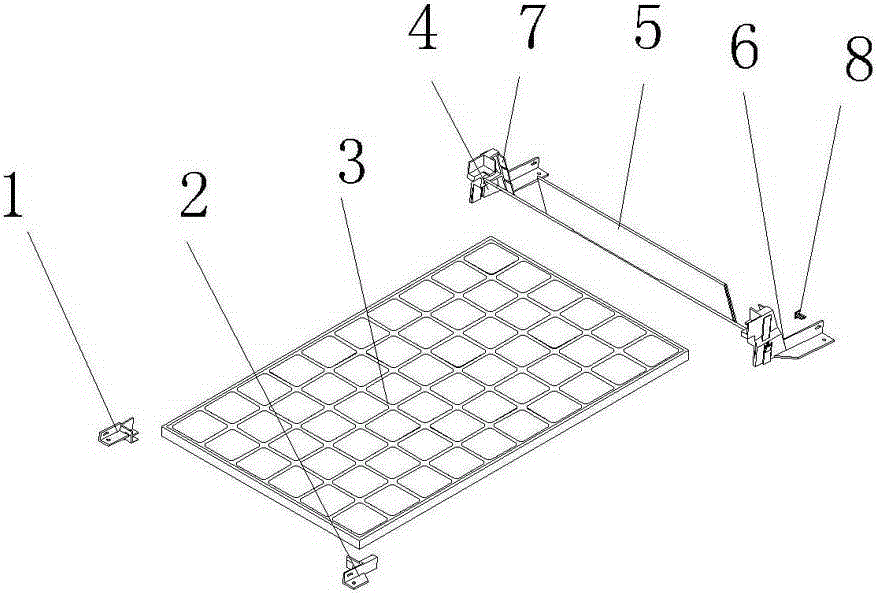

[0029] like figure 1 and 2 As shown, an installation structure of a photovoltaic power generation system includes a left front seat 1 , a right front seat 2 , a left rear seat 4 and a right rear seat 6 installed on four corners of a photovoltaic module 3 . A baffle plate 5 is connected between the left rear seat 4 and the right rear seat 6, and the baffle plate 5 is a profile, which is uniformly integrally formed on the opposite inner surface of the left rear seat 4 and the right rear seat 6 and has the same cross section as the baffle plate profile. The baffle plate connecting protrusion 7, the two ends of the baffle plate 5 are inserted respectively on the baffle plate connecting protrusion 7 of the left rear seat and the right rear seat, thereby realizing the connection of the baffle plate with the left rear seat and the right rear seat.

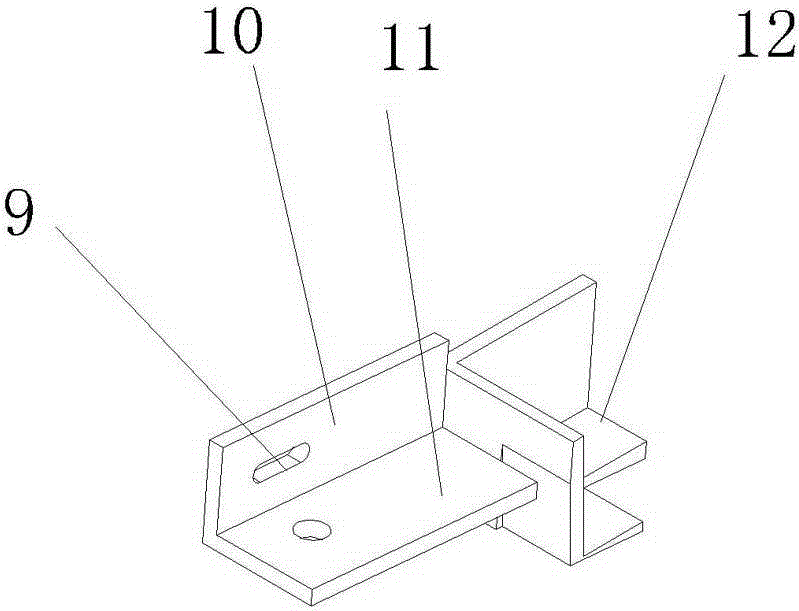

[0030] like image 3 As shown, the left front seat 1 includes a mounting base main body 12 , which is at a right angle, and the mounti...

Embodiment 2

[0037] like Figure 10 As shown, the difference from Embodiment 1 is that frame boards 21 are installed on the four sides of the photovoltaic module 3, and the frame board 21 is connected to the photovoltaic module 3 first, and then the front seat 18 and the rear seat 17 are installed on the frame board superior. The frame plate 21 is a profile structure. On the inner side of the front seat and the rear seat, there are protrusions that match the profile cross-section. Connections to front and rear seats. When carrying out, the auxiliary packing bracket 19 is fixed on the frame plate 21, which is convenient for transportation.

Embodiment 3

[0039] like Figure 11 and 12 As shown, the difference from Embodiment 1 is that the main body 12 of the mounting seat of the left front seat is matched with the right angle of the photovoltaic module, and a groove 14 is opened on the positioning plate 10 on the side of the main body 12 of the mounting seat. Similarly, in the left rear seat The positioning plate 10 on one side of the main body 12 of the mounting seat is provided with a protrusion 15 matching with the groove 14 .

[0040] At the same time, on the positioning plate 10 of the left front seat and the left rear seat, a connecting hole 9 is also provided, and the positioning plates of the left front seat and the left rear seat are connected together, and then passed through the connecting hole 9 through the pin shaft 8 to vertically The two photovoltaic modules arranged are fixed to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com