Multilayer flexible circuit board manufacturing method

A flexible circuit board and manufacturing method technology, which is applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit and other directions, can solve the problems of long manufacturing process, difficulty in inter-layer alignment, and long production time, so as to reduce process steps and save money. The effect of process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

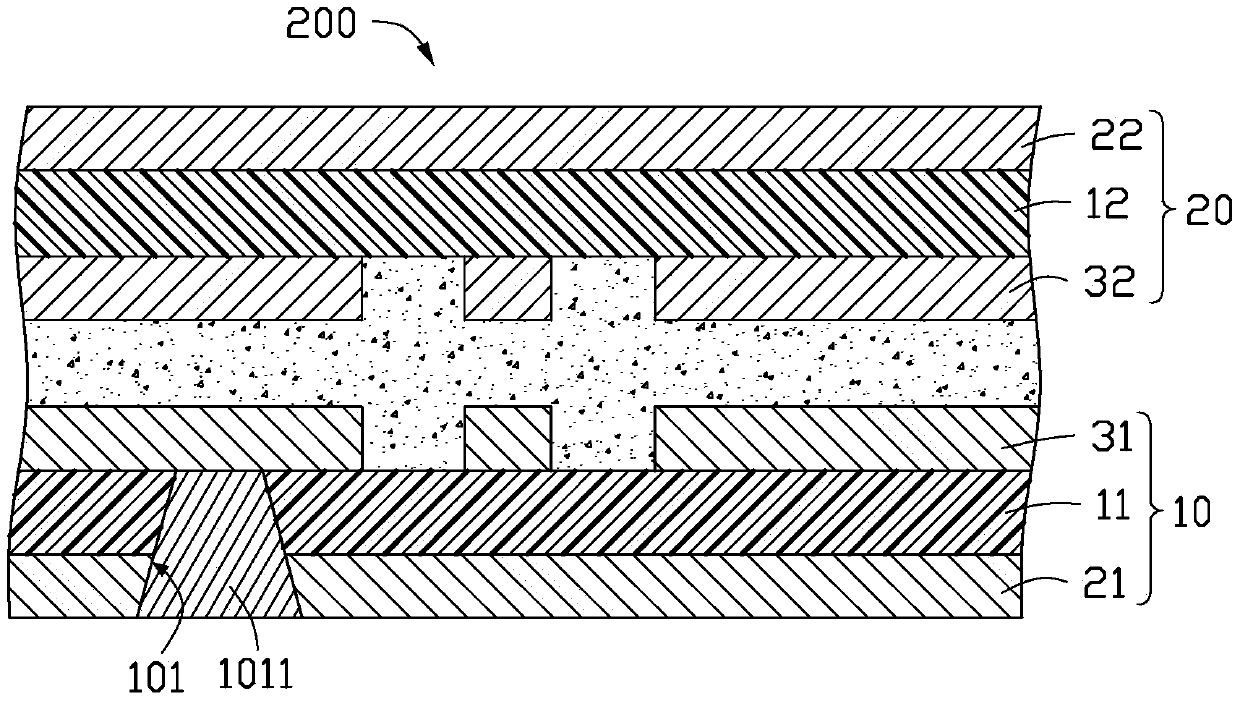

[0090] The following will be combined with Figure 1-19 and two embodiments, the multi-layer flexible circuit board provided by the technical solution and its manufacturing method are further described in detail.

[0091] Please refer to Figure 1-9 , the manufacturing method of the multilayer flexible circuit board 100a of the first embodiment of the present invention, it comprises the following steps:

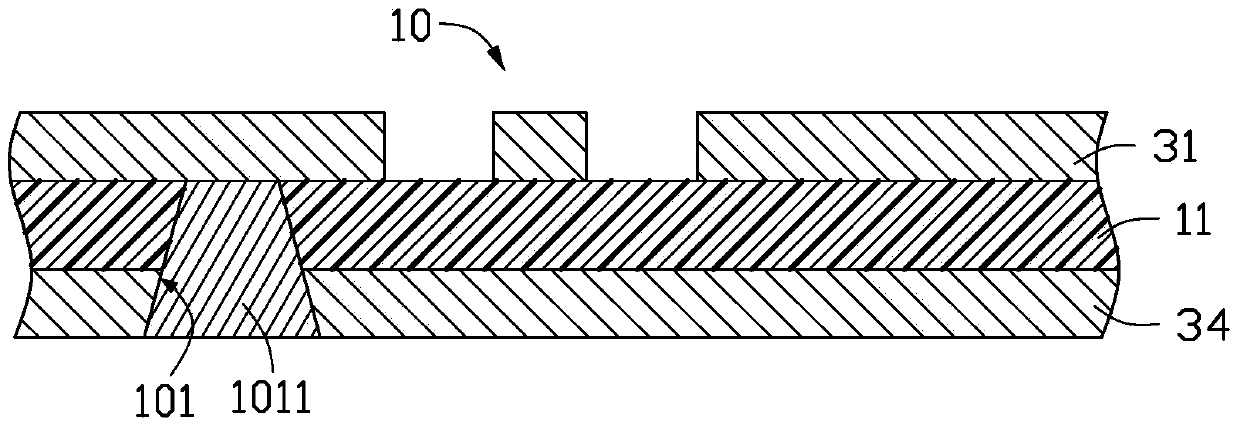

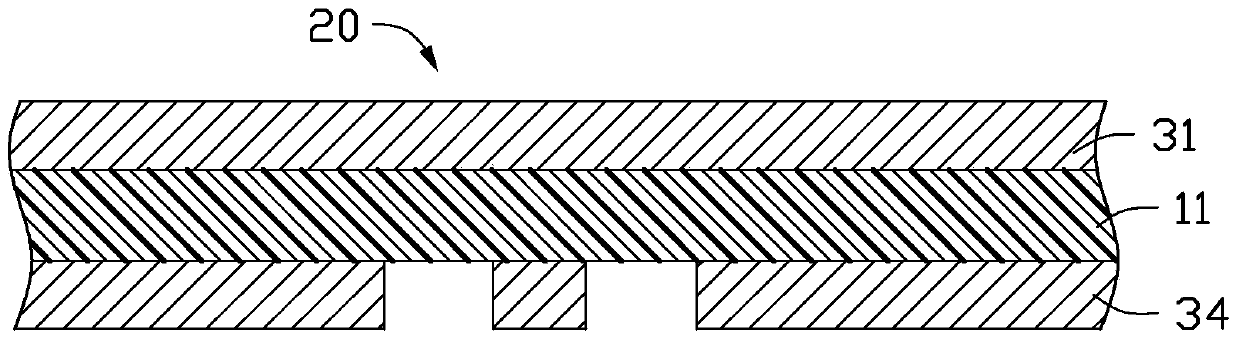

[0092] Step S1: See figure 1 , providing a first double-sided copper-clad laminate 10, the first double-sided copper-clad laminate 10 includes a first insulating layer 11, a first copper layer 21 bonded to a surface of the first insulating layer 11, and a first copper layer 21 bonded to the first The first inner conductive circuit layer 31 on the surface of the insulating layer 11 away from the first copper layer 21 . The first double-sided copper clad board 10 is provided with a first first-order blind hole 101, the opening of the first first-order blind hole 101 is opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com