Device for testing a fuel injector or a fuel injection nozzle

A technology of fuel injectors and fuel nozzles, applied in the field of fuel injectors or fuel nozzle devices, can solve the problems of non-reproducibility, inability to detect nozzle hole injection angle deviation, inability to test fuel departure, etc., and achieve the effect of simplified evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention relates to a device for testing fuel injectors or fuel nozzles of an internal combustion engine. For the sake of simplicity only the fuel nozzles are referred to next.

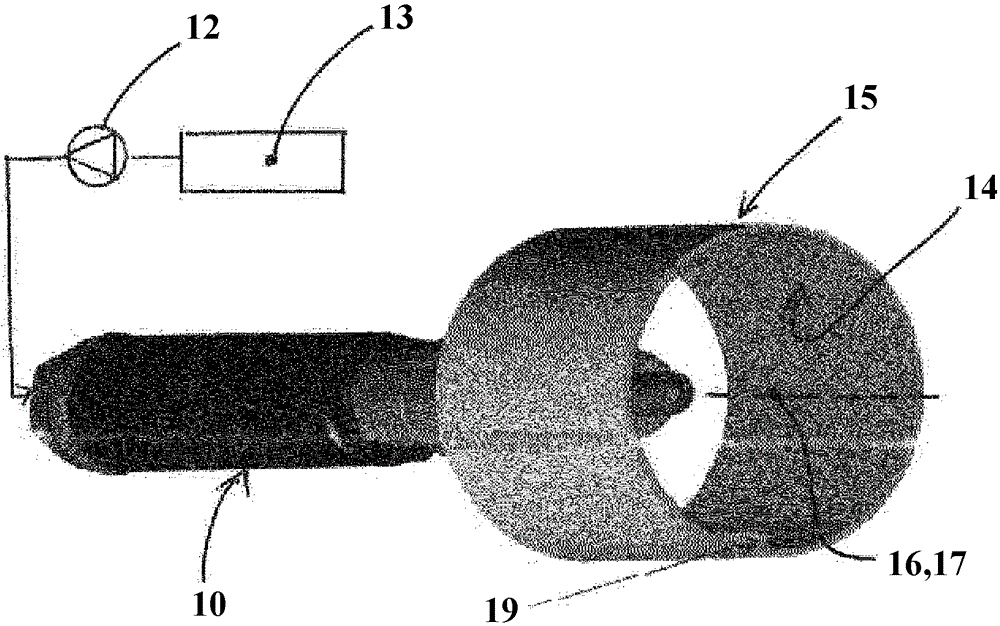

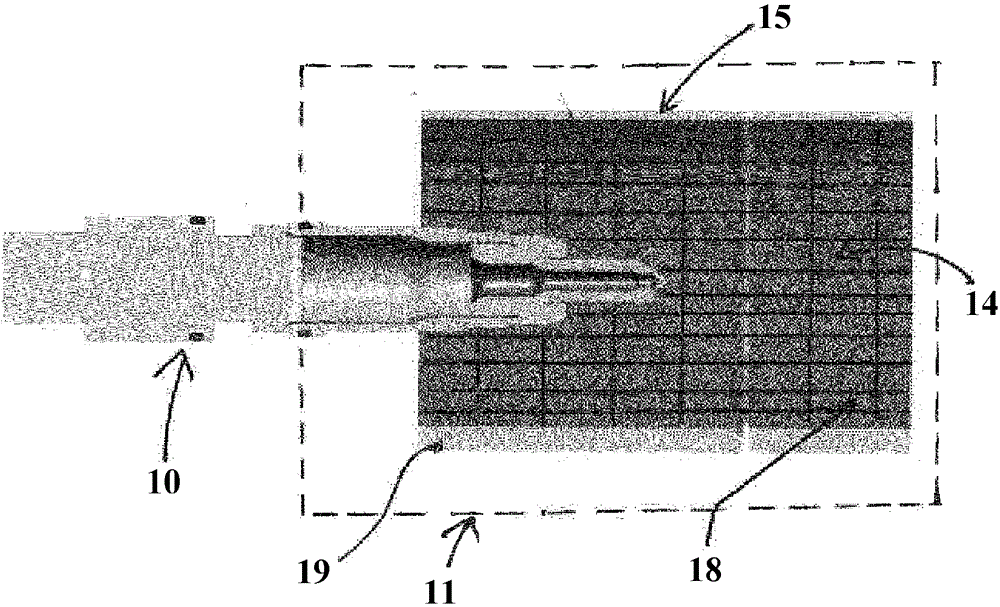

[0014] figure 1 and 2 Different views of a device for testing fuel nozzles according to the invention are schematically shown in connection with a fuel nozzle 10 to be tested, wherein according to figure 2 The fuel nozzle 10 to be tested protrudes into the test chamber 11 .

[0015] The device has a pump 12 , which generates an injection pressure for the fuel nozzle 10 to be tested, and fuel prepared in a tank 13 , which is supplied to the fuel nozzle 10 to be tested at a defined injection pressure. When testing the fuel nozzle 10 to be tested, it injects fuel into the test chamber 11 .

[0016] Within the meaning of the invention, the test chamber 11 accommodates a test strip 14 which, in the preferred embodiment shown, is accommodated by a holder 15 positioned within the test chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com