Error measurement workpiece perpendicularity rapid evaluation method based on single reference plane

A technology of error measurement and datum plane, applied in the direction of measuring devices, instruments, etc., can solve the problems that are not easy to promote tolerance evaluation, complex mathematical model form, difficult verticality evaluation, etc., to achieve simple evaluation method, industrial possibility, Effects that are easy to scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

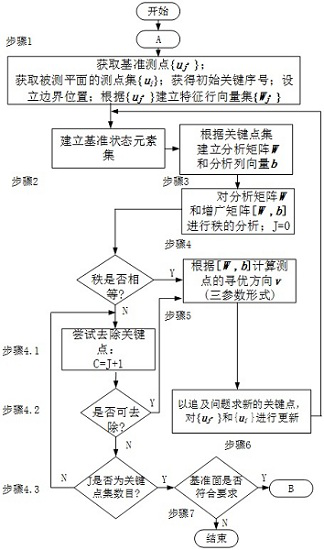

[0098] The following are specific examples of the present invention, and the solutions of the present invention will be further described with reference to the accompanying drawings, but the present invention is not limited to these examples.

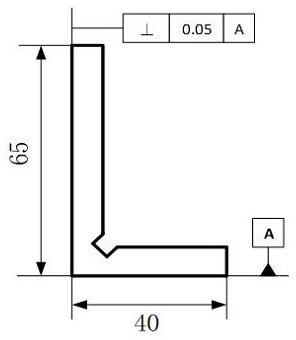

[0099] Evaluate the verticality error of an L-shaped measuring workpiece based on a single datum plane, and its tolerance design specifications are as follows image 3 shown.

[0100] Step 1: Get the measurement point set of the reference segment { u j ,} and the measuring point set of the measured segment { u i}as follows:

[0101]

[0102] At this time, the initial key sequence numbers are 6 and 8;

[0103] At this time, the position of the upper boundary of the datum plane is z' 6 =0.0514 and the lower bound is z' 8 =0.0014;

[0104] Obtain the middle position of the border as middle=0.0264;

[0105] Establish the feature row vector set of datum plane measuring point { W j ,}as follows:

[0106]

[0107] After step 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com