A seeder scriber

A liner and seeder technology, applied in planting methods, applications, agriculture, etc., can solve the problems of inconvenient maintenance, inconvenient operation, inflexible lifting, etc., achieve convenient disassembly and maintenance, convenient operation, and speed up the conversion time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

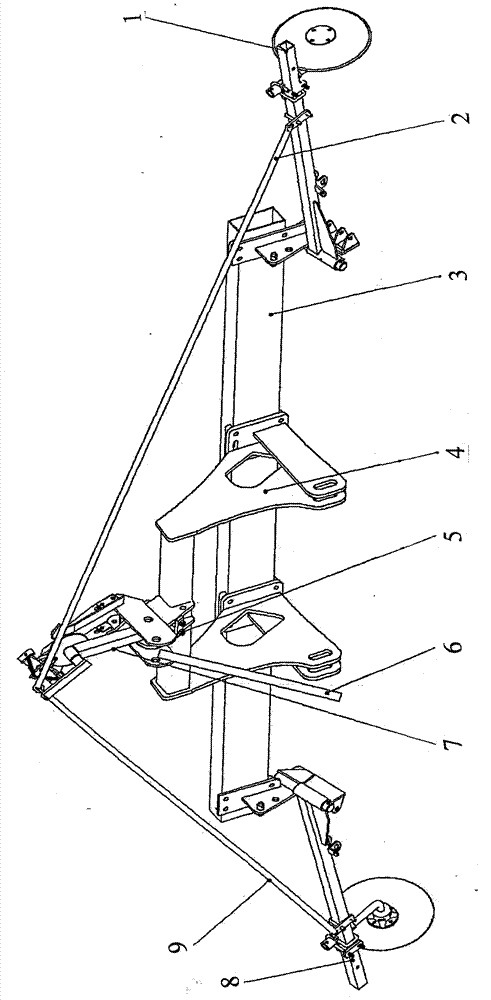

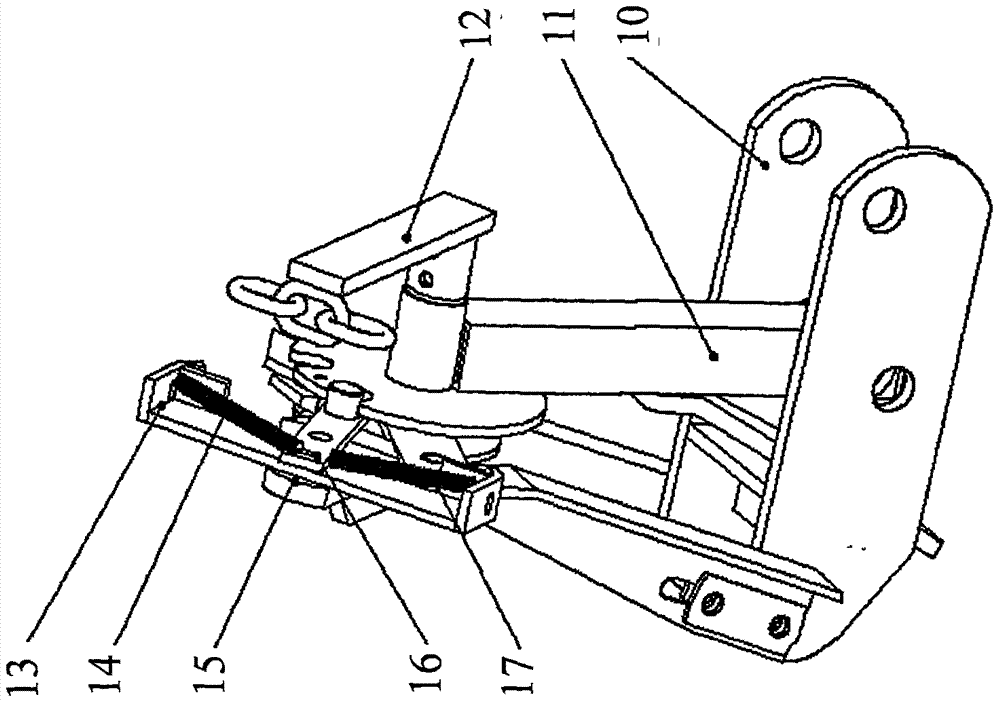

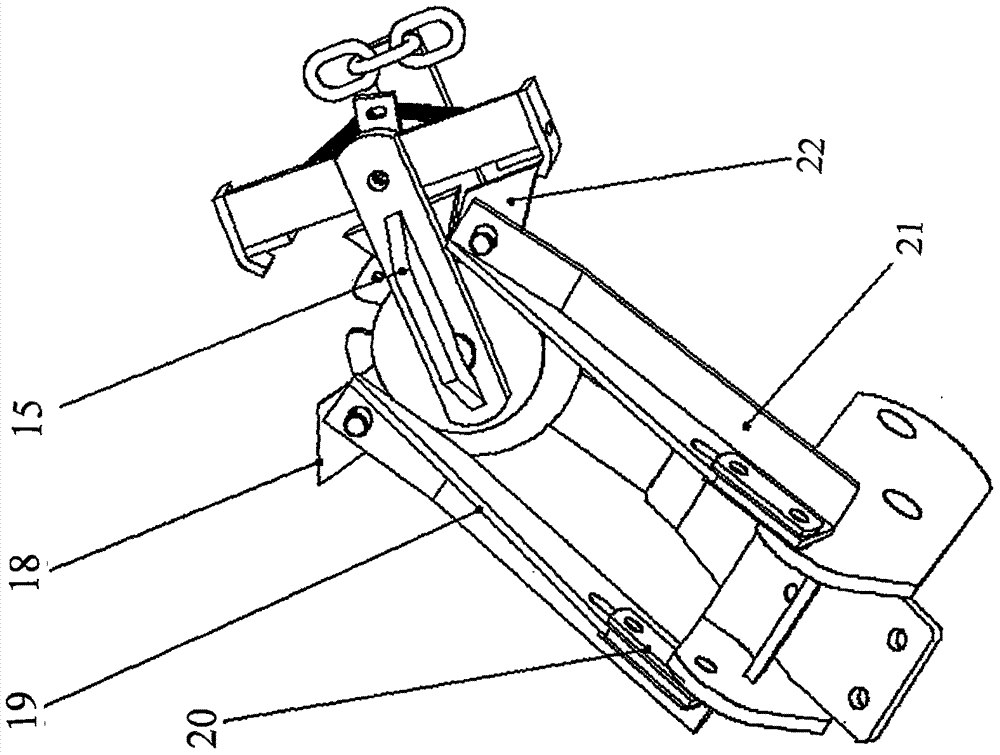

[0011] When the seeder operates on the cultivated land, the center pull rod 6 is controlled to descend so that the seeder is in working condition. like figure 1 As shown, the right marker arm assembly 8 is in contact with the cultivated land, and the left marker arm assembly 1 is off the ground. Now the right limit connecting frame welding 22 and the rotating frame welding 15 fit together and are fixed together by the spring fixing frame welding 13. When the scriber needs to be converted, the central pull rod 6 rises to drive the base welding 10 to rotate and rise. Along with base welding 10 rotation rises, drive left lifting movable plate 19, right lifting movable plate 21 to move upwards, when it moves to the highest point, right limit connecting frame welding 22 separates with spring fixed frame welding 13, spring The fixed frame welding 13 rotates to the left under the elastic force of the left spring 14 and is in a suspended state. At this time, the left scriber support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com