A concentric double-helix hydrate continuous reaction device

A reaction device, hydrate technology, applied in chemical/physical/physical chemical fixed reactor, gas fuel, petroleum industry, etc., can solve the problem of high energy consumption of stirred reactor, hindrance of subsequent contact between liquid and gas, shortening Hydrate induction time and other issues, to achieve continuous high-efficiency preparation, increase the gas-liquid contact area, and avoid clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

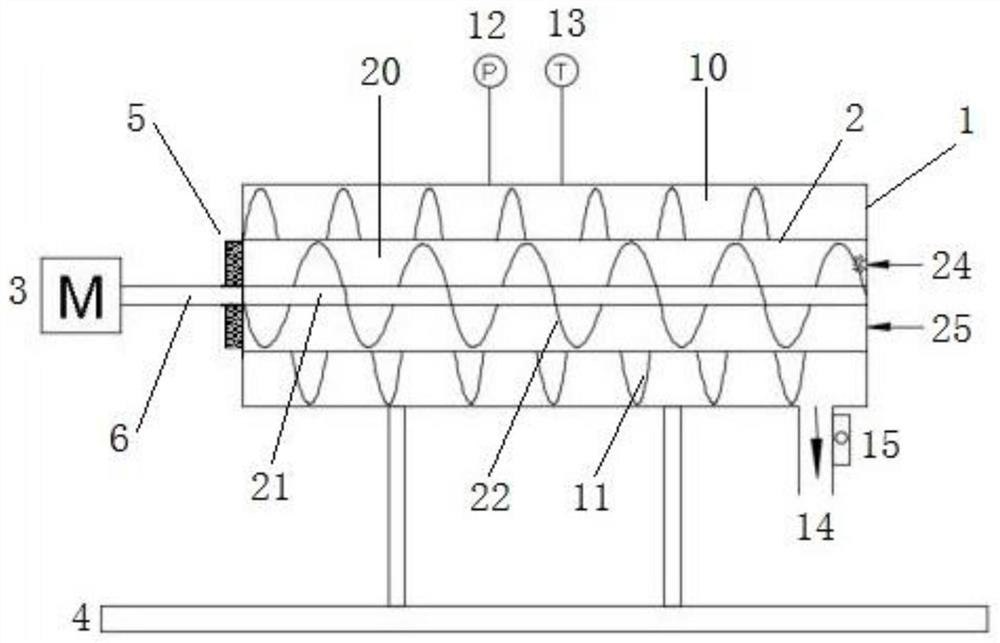

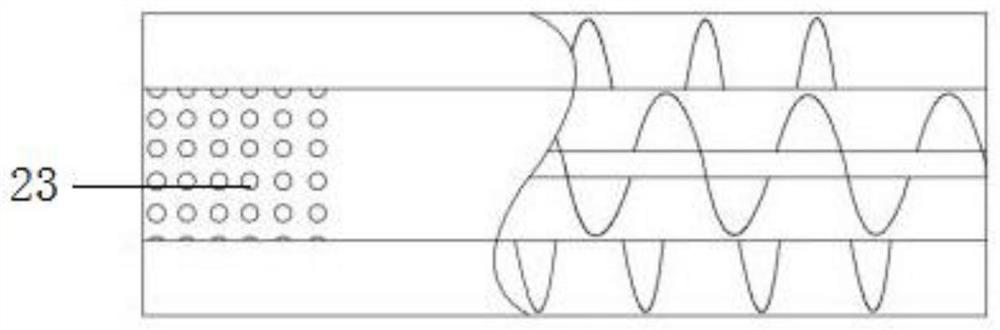

[0015]The main structure of the concentric double-helix hydrate continuous reaction device involved in this embodiment includes an outer reactor 1, a central reactor 2, a motor 3, a bracket 4, a gear 5 and a magnetic transmission rod 6; A central reactor 2 is set in the reactor 1, and the central reactor 2 is driven by a motor 3; the main structure of the outer reactor 1 includes an outer cylinder 10, an outer stirring blade 11, a pressure sensor 12, a temperature sensor 13, a discharge port 14 and a ball valve 15; the outer cylinder 10 is provided with an outer stirring blade 11, the upper part of the outer cylinder 10 is provided with a pressure sensor 12 and a temperature sensor 13, and the lower part of the outer cylinder 10 is provided with a discharge port 14, and the discharge port 14 A ball valve 15 is arranged at the center; the main structure of the central reactor 2 includes a central cylinder 20, a stirring rod 21, a central stirring blade 22, a through hole 23, a l...

Embodiment 2

[0017] When the concentric double-helix hydrate continuous reaction device involved in this embodiment is used, gas is introduced from the air inlet 25 to flush the outer reactor 1 and the central reactor 2, and the air is removed. When the outer reactor 1 and the central reactor 2 When the internal temperature of the reactor reaches 1°C, the gas is fed again to make the internal pressure of the outer reactor 1 and the central reactor 2 reach 7MPa and remain constant, the motor 3 is turned on, the rotating speed is set to 30r / min, and the liquid injection port 24 is opened, and the liquid It is sprayed into the central reactor 2 in the form of micro-droplets. Under the continuous agitation of the central stirring blade 22, the gas and the micro-droplets are fully mixed and quickly generate hydrate particles. Driven by the central stirring blade 22, the hydrate particles are driven from right to The left gradually moves to the left end of the central reactor 2, enters the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com