Multi-stage cyclone machanism and dust cup structure

A tornado and cyclone technology, applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems such as the decline of the filter level of the dust cup, the influence of the dust collection efficiency of the vacuum cleaner, and the dust-filled space falling into the cyclone system, so as to facilitate the cleaning of dust, Improved module disassembly and improved filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

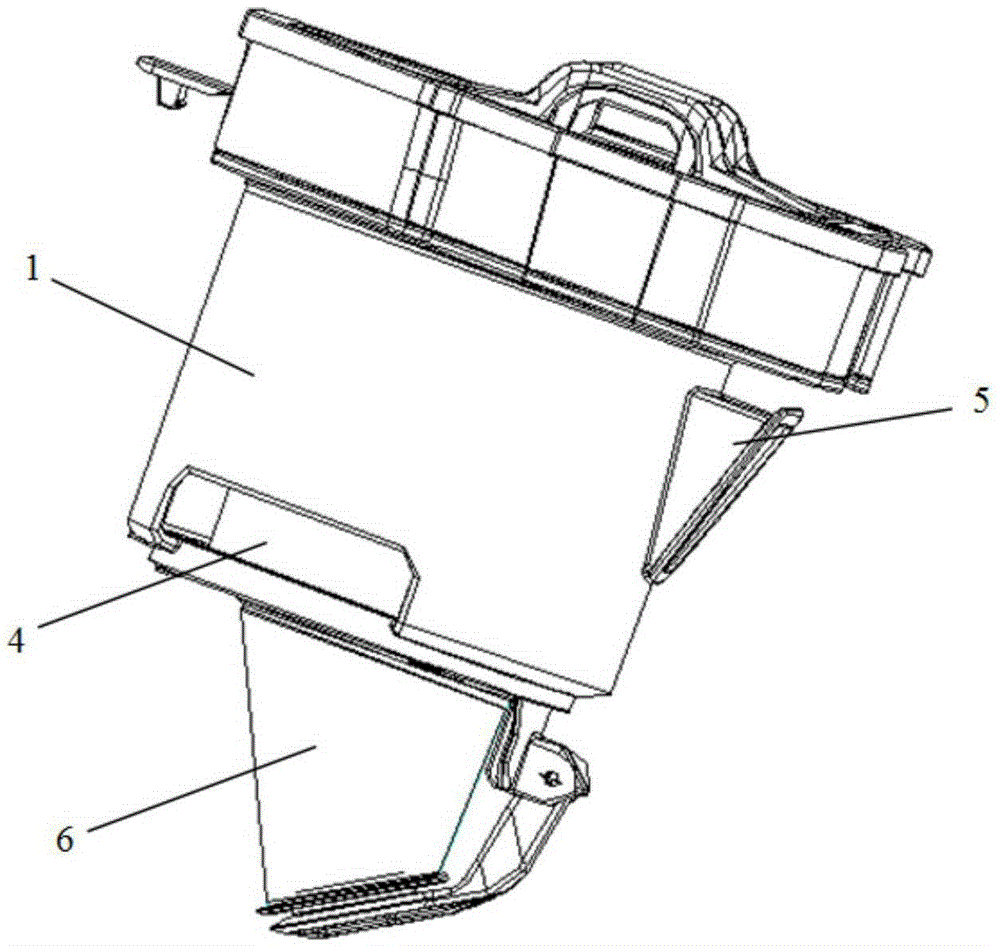

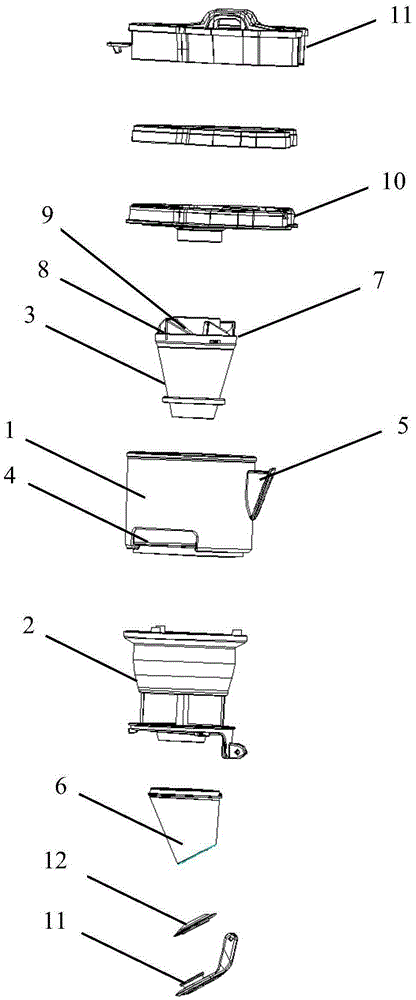

[0025] In the traditional multi-level tornado system, the first-level cyclone space is composed of the main body of the dust cup and the first-level cyclone net cover, so that the first-level ash storage space and the first-level cyclone space are in the same space, and the first-level cyclone space will collect most of the dust. It is thrown into the primary ash storage space by centrifugal force. At the same time, the dust in the ash storage space is easily brought into the secondary cyclone system by the primary cyclone net cover with meshes, resulting in a decrease in the filtration level of the entire dust cup. .

[0026] Aiming at the deficiencies in the prior art, the present invention provides a multi-stage tornado cyclone mechanism, which includes an independent primary cyclone cylinder. The technical solutions of the present invention will be clearly and completely described below through specific embodiments. Apparently, the described embodiments are only some of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com