Crusher with good crushing effect

The technology of a pulverizer and a pulverization chamber, which is applied in the direction of grain processing, etc., can solve problems such as the unsatisfactory pulverization effect, the inconvenient handling of the pulverizer, and the inability to achieve the pulverization effect, etc., so as to achieve easy promotion, avoid power waste, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

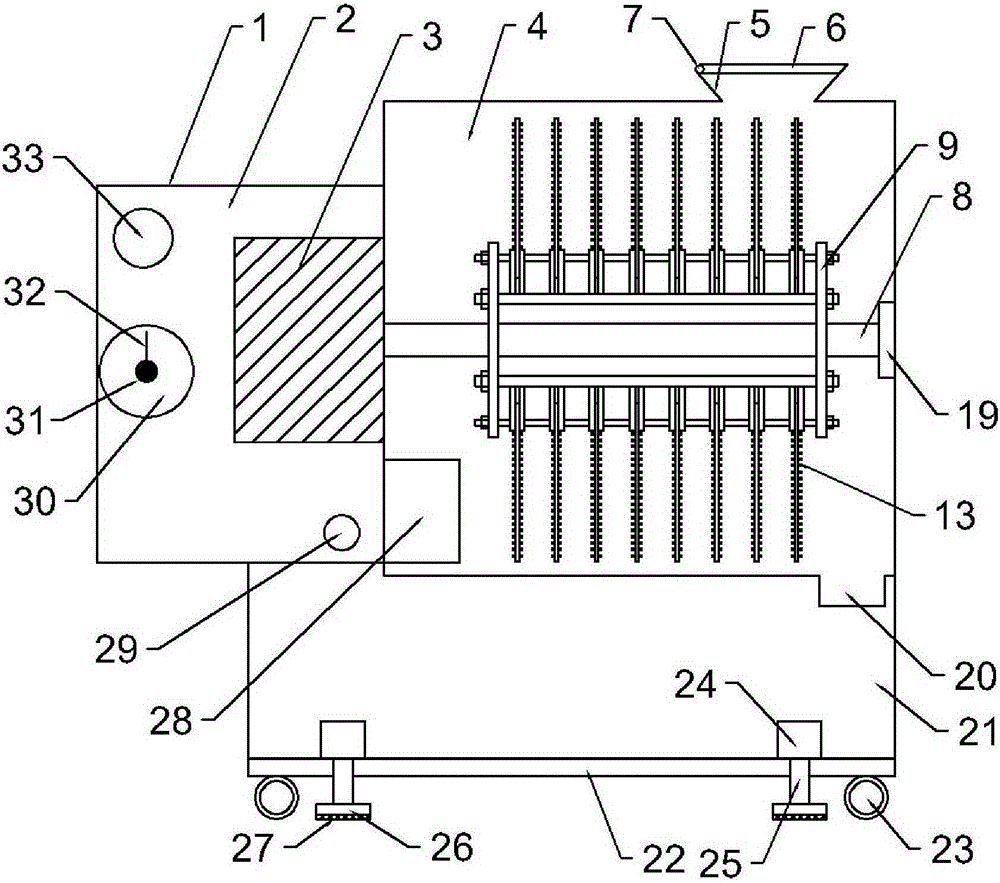

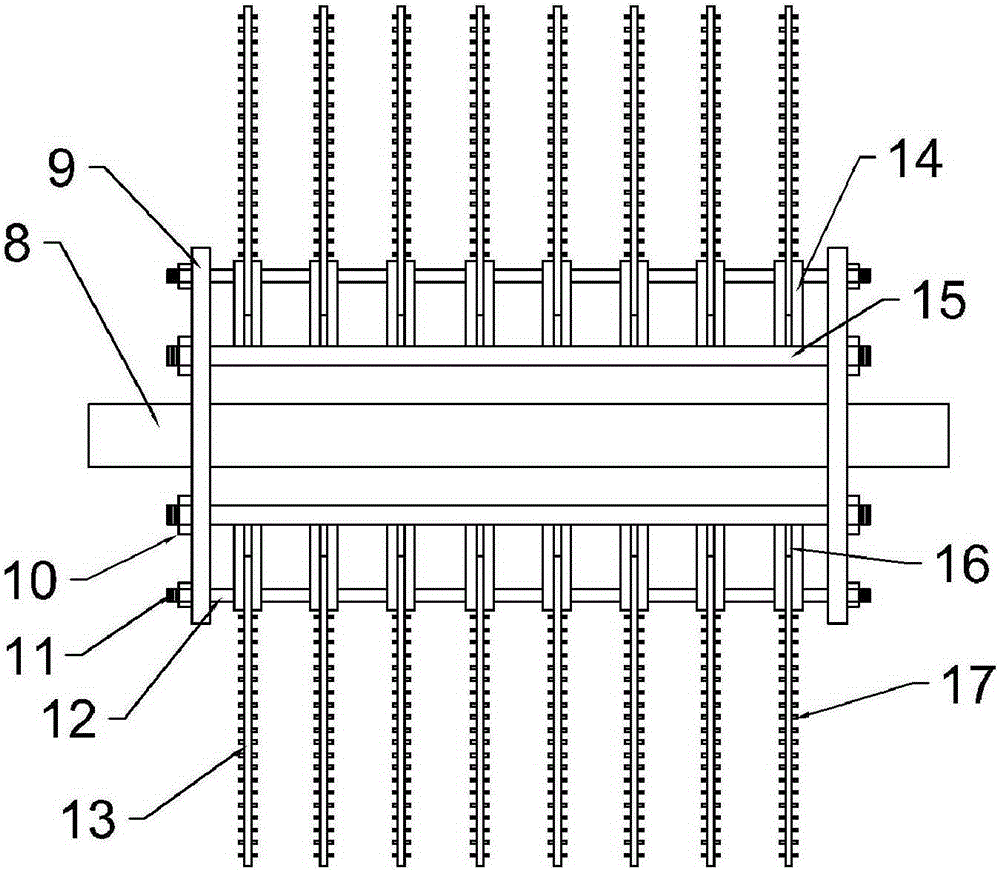

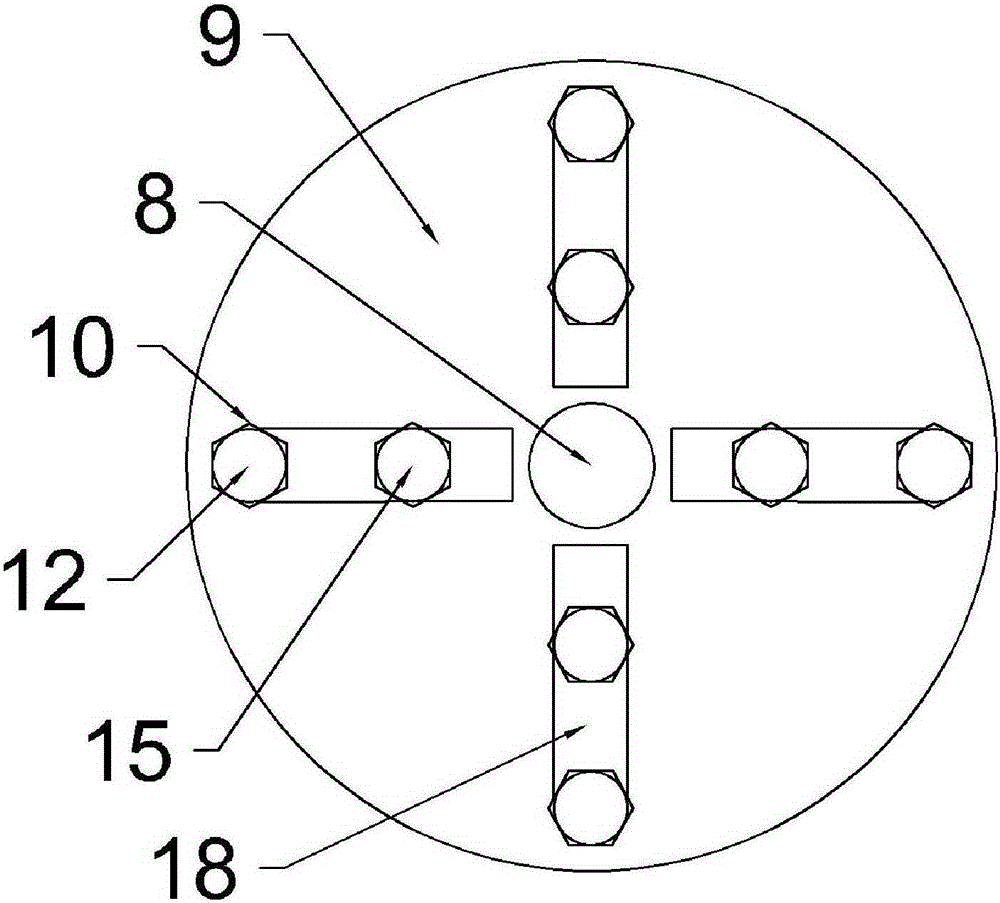

[0016] see Figure 1-4 , a pulverizer with good crushing effect, comprising a body 1, the body 1 includes a motor chamber 2 on the left side, a pulverization chamber 4 on the right side, and a support frame 21 arranged at the bottom of the motor chamber 2 and the pulverization chamber 4, the The motor chamber 2 is fixedly connected with the crushing chamber 4, the motor chamber 2 is provided with a motor 3, the top of the crushing chamber 4 is provided with a feeding funnel 5, and the left side of the feeding funnel 5 is connected with a cover plate 6 through a rotating shaft 7, and the crushing chamber 4 There is a crushing cutter inside, and the crushing cutter includes a rotating shaft 8 and a spoke 9, the left end of the rotating shaft 8 is connected with the motor 3, the right end of the rotating shaft 8 is connected with a bearing 19, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com