A device for removing debris from a counting machine and its removing method

A technology of rejecting device and counting machine, which is applied in packaging, transportation and packaging, and the type of packaged items, can solve the problems that the fragments of the counting machine affect production, etc., and achieve the goal of removing defective products, increasing the rigidity of the system, and ensuring stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

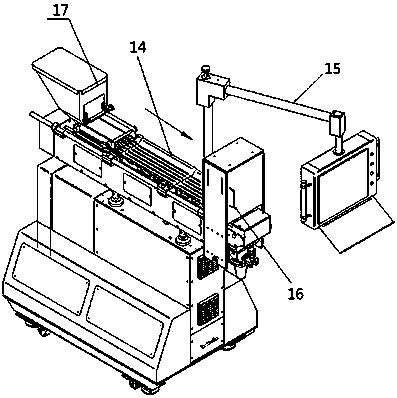

[0024] The structure of the debris removal device of the counting machine of the present invention is as figure 1 As shown, the medicine granules to be filled (or other solid particles, the same below) are placed in the silo 17, the medicine granules move through the medicine supply system, and are sent to the detection system 16 by the discharge track 14 for detection, and the detection results are sent to To the calculation and control system 15, judge the integrity of the medicine grains and at the same time send the position of the incomplete medicine grains to the control unit to issue a rejection command to prevent the medicine grain fragments from flowing into the next station.

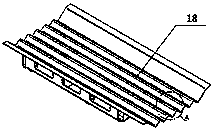

[0025] Such as figure 2 As shown, the blanking track 14 is designed as a V-shaped groove to prevent material stacking and improve the blanking efficiency. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com