System for detecting and correcting quenching deformation of gear rings through static pressure

A technology of quenching deformation and correction system, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high labor intensity, low work efficiency, easily damaged ring gear, etc., and achieve low labor intensity and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

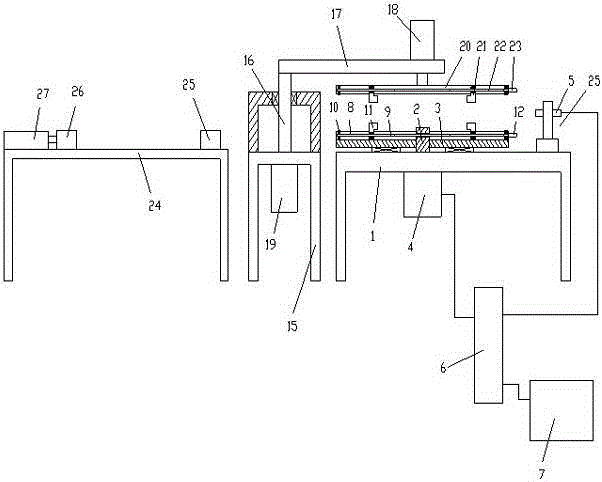

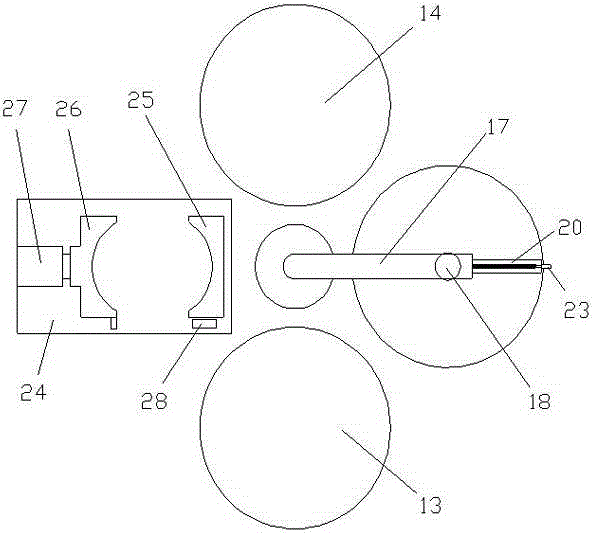

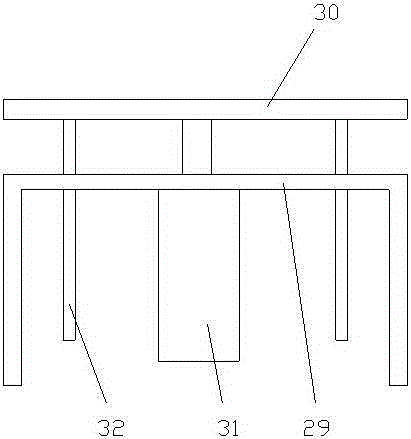

[0018] As shown in the figure, the static pressure correction system for detecting the quenching deformation of the ring gear in this embodiment includes a detection unit, a loading and unloading unit, and a correction unit.

[0019] The detection unit includes a support platform 1, a mandrel 2 vertically arranged on the support platform and rotatably matched with the support platform, a rotating platform 3 fixed on the mandrel, a first rotor arranged under the support platform and connected to the mandrel. Servo motor 4, electronically controlled positioning device set on the rotating platform, sensor supporting device set on the support platform, inductive sensor 5 set on the sensor supporting device, used to process the detection signal of the inductive sensor and control the servo motor The industrial computer 6 and the display 7 connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com