Electric spark discharging machining device special for PCD materials

A technology of electrical discharge machining and electric spark, which is applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of ineffective processing of polycrystalline diamond, achieve smoothness improvement, realize real-time detection, and improve accuracy and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

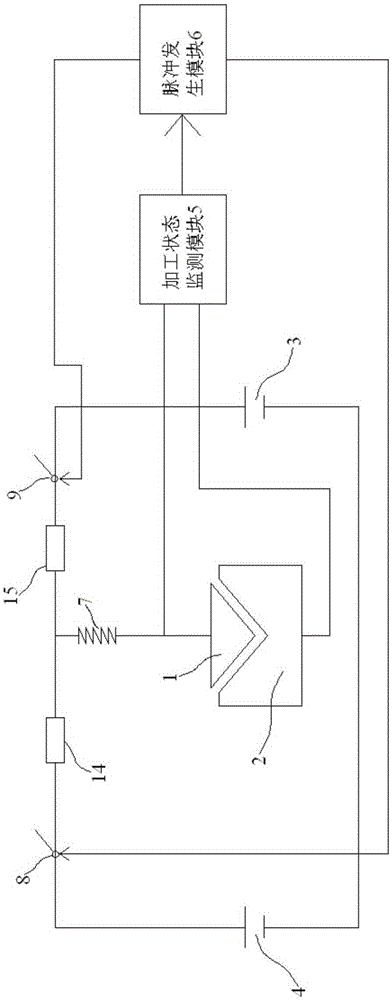

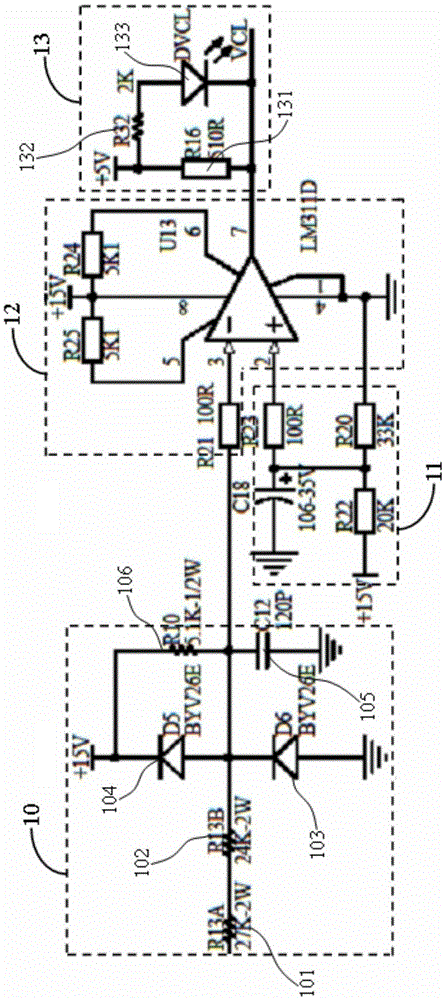

[0017] Embodiment 1: An EDM device dedicated to PCD materials, including a positive electrode 1, a negative electrode 2 connected to the PCD material to be processed, a high-voltage discharge power supply 3, a low-voltage discharge power supply 4, a processing state monitoring module 5, and a pulse Generating module 6, the positive electrode 1 is connected in series with one end of an inductor 7, and after the low-voltage discharge power supply 4 is connected in series with a low-voltage power switch tube 8, one end of the low-voltage positive side is connected to the other end of the inductor 7, and the corresponding low-voltage negative One end of the side is connected to the negative electrode 2, thereby forming a low-voltage discharge circuit; after the high-voltage discharge power supply 3 is connected in series with a high-voltage power switch tube 9, one end of the high-voltage positive side is connected to the other end of the inductor 7, and one end of the corresponding...

Embodiment 2

[0021] Embodiment 2: An EDM device dedicated to PCD materials, including a positive electrode 1, a negative electrode 2 connected to the PCD material to be processed, a high-voltage discharge power supply 3, a low-voltage discharge power supply 4, a processing state monitoring module 5, and a pulse Generating module 6, the positive electrode 1 is connected in series with one end of an inductor 7, and after the low-voltage discharge power supply 4 is connected in series with a low-voltage power switch tube 8, one end of the low-voltage positive side is connected to the other end of the inductor 7, and the corresponding low-voltage negative One end of the side is connected to the negative electrode 2, thereby forming a low-voltage discharge circuit; after the high-voltage discharge power supply 3 is connected in series with a high-voltage power switch tube 9, one end of the high-voltage positive side is connected to the other end of the inductor 7, and one end of the corresponding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com