Big sack packing machine

A packaging machine and large bag technology, applied in packaging, paper product packaging, transportation and packaging, etc., can solve the problems of non-compliance with green environmental protection policies, uneven bag sealing, waste of transparent tape, etc., to achieve flexible adjustment methods and cutting Beautiful cutting and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, invention is described in further detail.

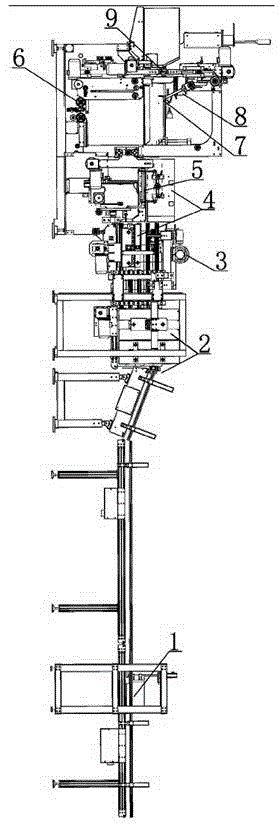

[0010] As shown in Figure 1, the large bag packaging machine includes a servo distribution device 1, a servo palletizing device 2 provided on one side of the servo distribution device 1, a servo main pushing device 3 provided on the servo palletizing device 2, a servo The material sorting device 4 provided on the main push handle device 3, the servo lifting device 5 provided on the material sorting device 4, and the automatic bagging and sealing discharging device provided on the servo lifting device 5;

[0011] Described automatic bagging and sealing discharge device comprises automatic film feeding device 6, the molding die device 7 that is provided with on automatic film feeding device 6, the big edge seal heat sealing device 8 that is provided with on molding die device 7 and The sealing and cutting device 9 that is provided with on the large side sealing hot sealing device 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com