Double channel guide plate switching platform for strip steel

A dual-channel, guide plate technology, applied in the direction of coiling strips, thin material handling, transportation and packaging, can solve the problems of economic loss of production, affecting the operating efficiency of the unit, and large swing of the guide plate, ensuring smooth switching, Simple structure and quick action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

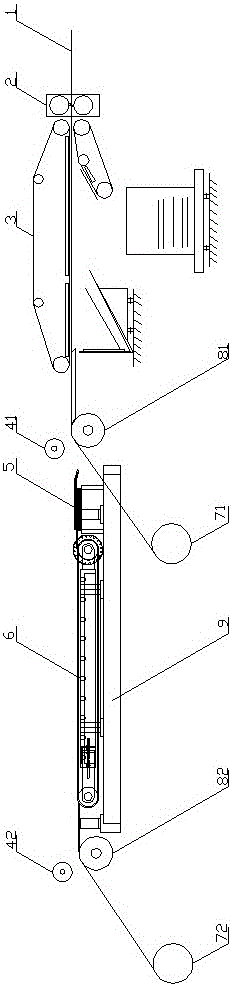

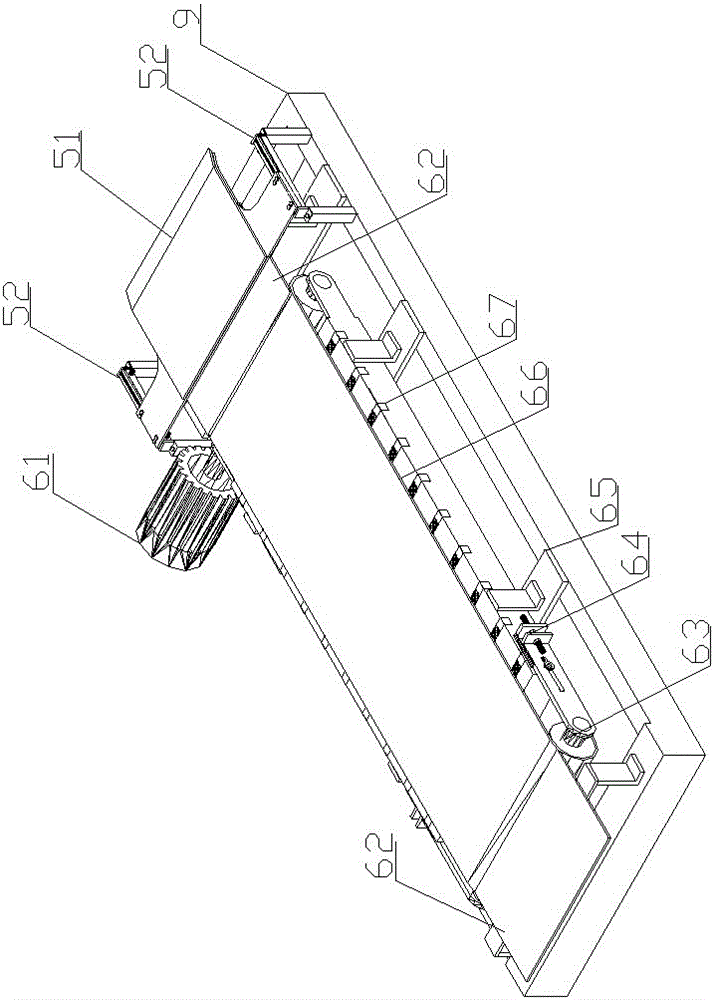

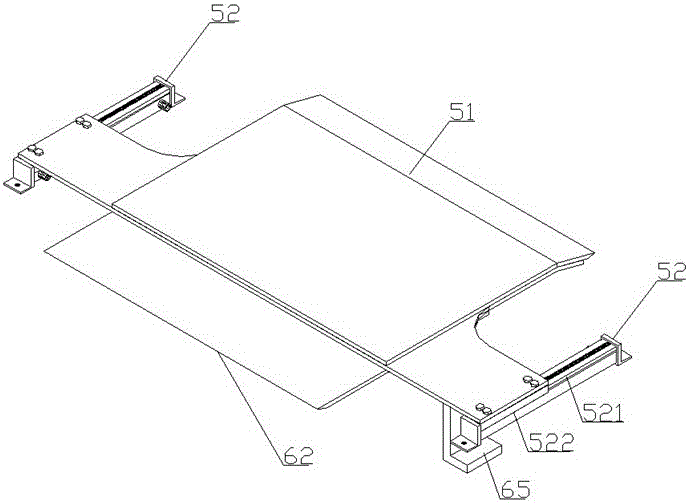

[0025] Such as Figure 1-3 As shown, the double-channel guide plate switching platform for strip steel in this embodiment includes a switch guide plate 5, an electromagnetic transport belt 6 and a strip steel turning roller set. The switching guide plate 5 adopts the design method of moving along the horizontal direction of the unit operation line. Compared with the upper and lower action guide plates, the action stroke of the oil cylinder is greatly shortened; after the switching guide plate 5, an electromagnetic transport belt 6 is designed, and the electromagnetic transport belt 6 is designed. The transport belt 6 adopts the electromagnetic adsorption force to tightly adsorb the steel strip 1 on the belt, which effectively avoids the deviation of the steel strip 1 during the tension-free belt threading process, and at the same time avoids the problems caused by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com