A kind of processing method of adhesive product

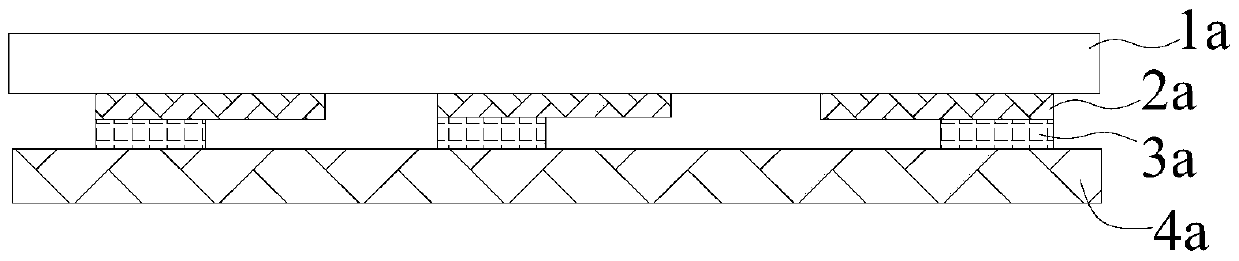

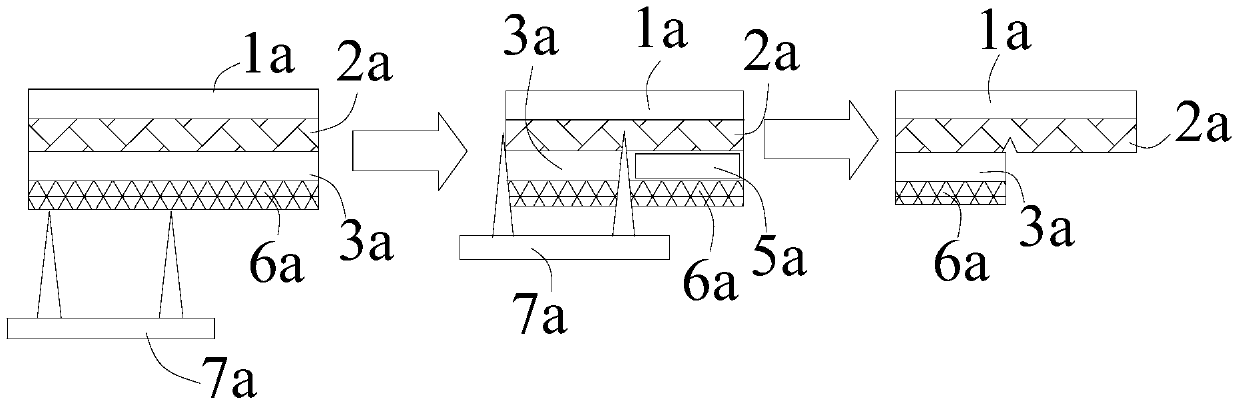

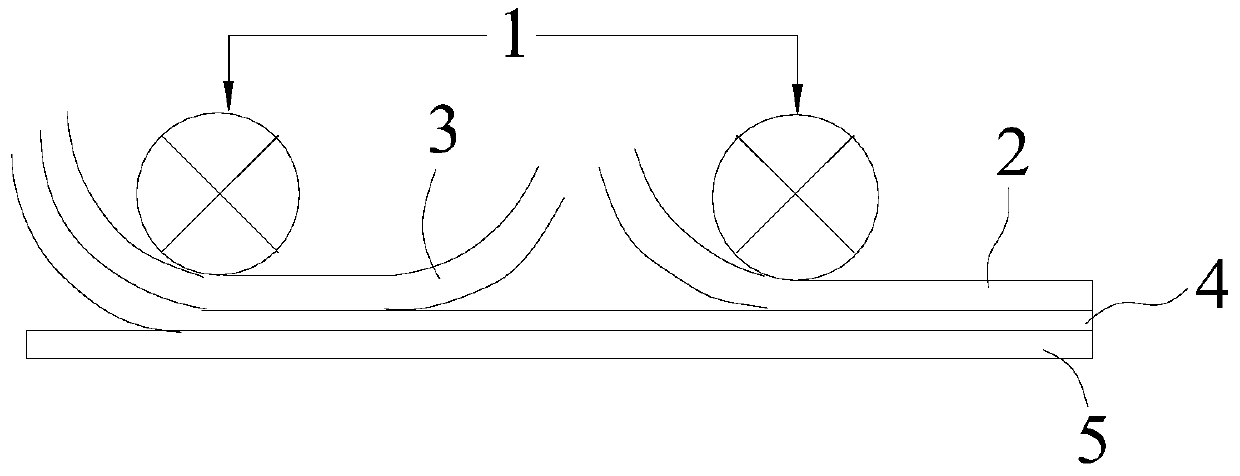

A processing method and technology for sticking products, applied in metal processing, films/sheets without carriers, etc., can solve the problems of breakage of the release film 2a, ineffective control, double-sided adhesive overflow, etc., to ensure product quality, improve Die-cutting process, the effect of reducing the difficulty of inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] Before processing the adhesive product of this embodiment, carry out mold design earlier:

[0032] ① Make the double-sided adhesive die-cutting forming tool according to the size of the glue marked on the finished drawing. One or more forming knives can be arranged on the double-sided adhesive die-cutting forming tool. The length / width of the forming knife is the same as the length of the drawing standard / Width is the same; if there are multiple forming knives, the distance between them is made according to the size of the glue marked on the drawing; depending on the complexity of the shape of the double-sided tape and the difficulty of waste removal, set a set of die-cutting die-cutting or multiple sets of die-cutting forming.

[0033] ② Make the release film die-cutting tool according to the size of the release film glue marked on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com