Reinforcing core of fiber-reinforced copper matrix composite contact wire

A copper-based composite material and fiber-reinforced technology, applied in the field of contact wires, can solve the problems of easy peeling of the metal reinforced core from the matrix material, different electrode potentials, electrochemical corrosion, etc., to increase the maximum suspension tension, enhance bonding, and improve The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

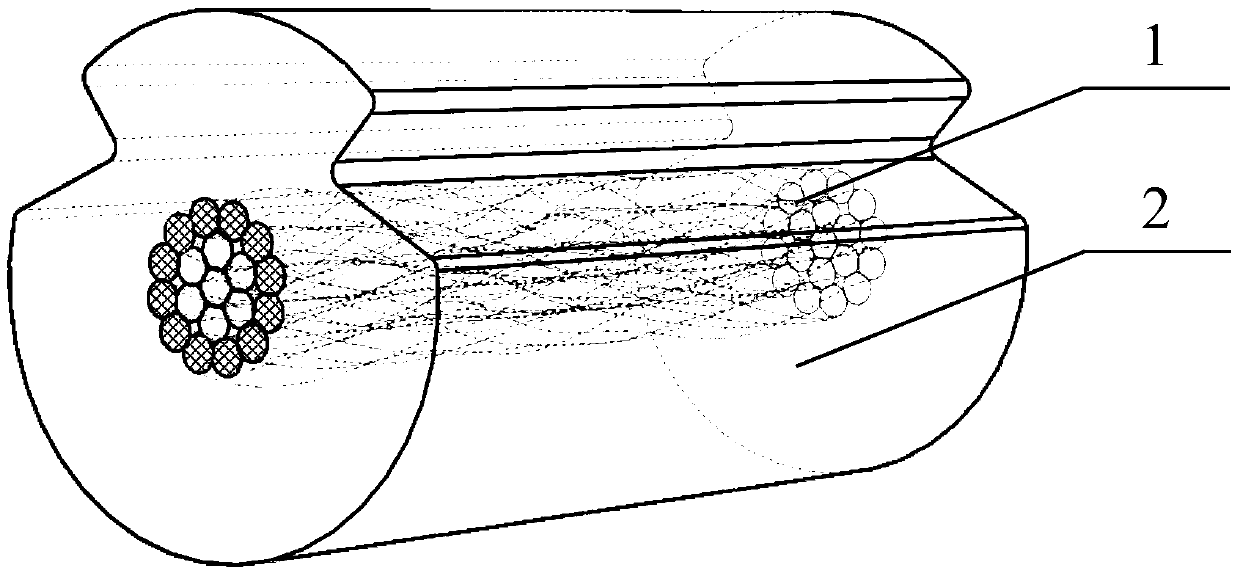

[0041] Take the 12K fiber bundle of T700SC carbon fiber and tin-copper (the tin content is 0.15% mass fraction ratio) alloy wire, place it in a braiding machine for interlaced braiding, and the obtained reinforcing core is as follows: figure 2 As shown, in an Ar gas protective atmosphere, copper cladding and rounding are performed on the reinforcing core.

[0042] In its characteristic cycle section, it can be regarded as a triangular substructure 5 composed of 2 bundles of carbon fiber bundles 3 and a copper alloy wire 4, and 6 triangular substructures 5 are tightly wrapped around a copper alloy wire, and then all The triangular substructure 5 is helically drawn out, and the spin directions of adjacent triangular substructures 5 are opposite. In a characteristic cycle section of the reinforcing core in this embodiment, it can be seen that the triangular substructure 5 is spirally drawn out along the axial direction, during which the triangular substructure spins 360° and clo...

Embodiment 2

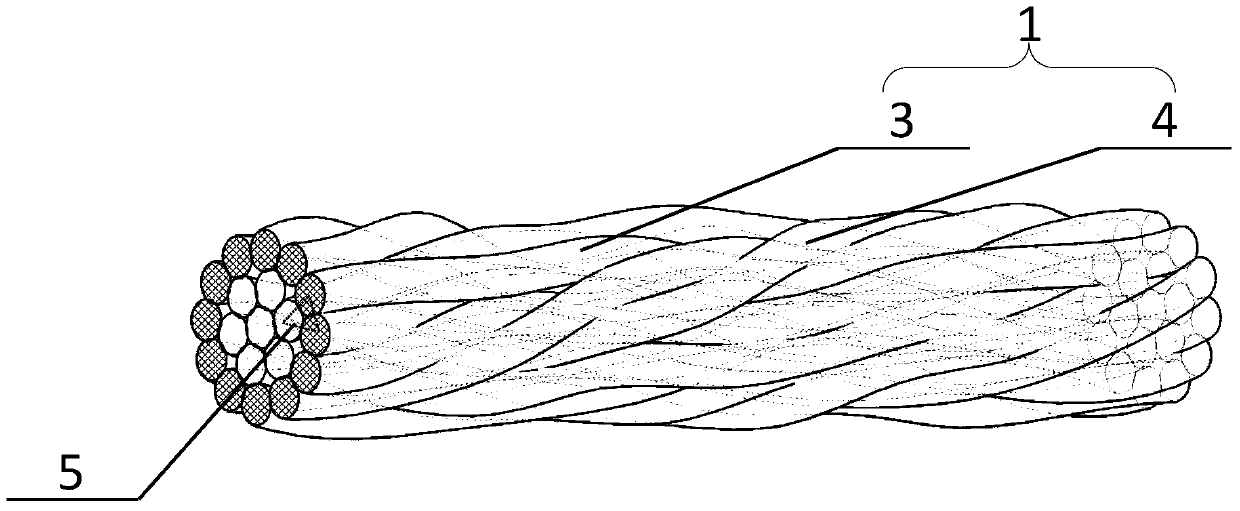

[0044] Get the fiber bundle of SYT49 type carbon fiber and silver-copper alloy wire (silver content is 0.10% mass fraction ratio), be placed in braiding machine and carry out interlaced braiding process, the reinforced core that obtains is as follows image 3 As shown, in the N2 gas protective atmosphere, the reinforced core will be covered with copper and rounded.

[0045] In the general circulation section of the reinforced core, it can be regarded as a paired substructure 6 composed of a bundle of carbon fiber bundles 3 and a copper alloy wire 4, and eight paired substructures 6 are tightly surrounded and then spirally drawn out. Adjacent pairs of substructures 6 have the same helical direction. In this embodiment, the carbon fiber bundle 3 and the copper alloy wire 4 have the same cross-sectional diameter. In the characteristic section of the reinforcing core, the area ratio of the carbon fiber bundle 3 to the copper alloy wire 4 is close to 1:1.

Embodiment 3

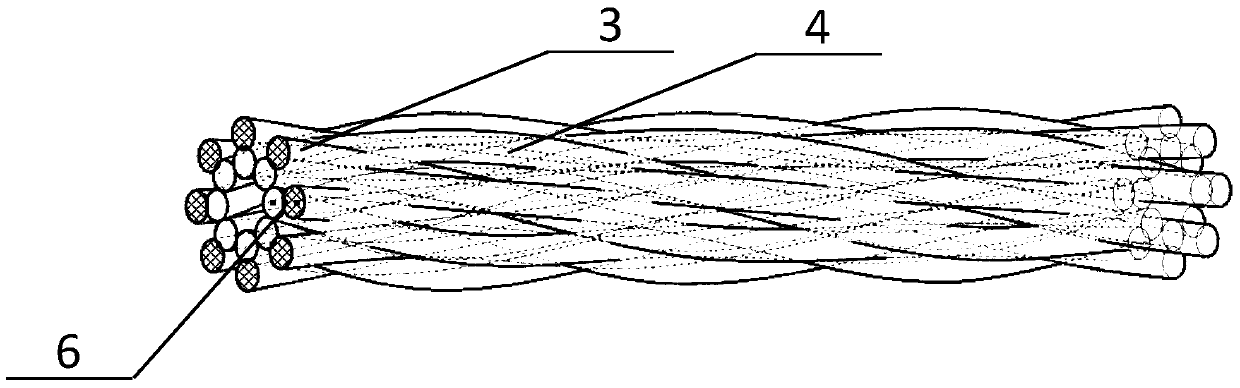

[0047] Take the fiber bundle of SYT50 carbon fiber, put it in the braiding machine for interlacing braiding, and the obtained reinforcing core is as follows: Figure 4 As shown, in a vacuum atmosphere, copper-clad plus rounding treatment is performed on the reinforcing core.

[0048] In the characteristic circulation section of the reinforcing core, mainly composed of carbon fiber bundles, which have the same type and diameter. This embodiment adopts a layered structure, and in each layer, carbon fiber bundles 3 with the same diameter are uniformly distributed along the circumferential direction to form a ring substructure 7, and the number of carbon fiber bundles 3 contained in the inner layer to the outer layer is 1, 6, and 12 respectively. , 18. The carbon fiber bundles 3 of all layers are spirally drawn out along the axial direction, and the directions of the carbon fiber bundles 3 of any two adjacent layers are opposite.

[0049] In summary, the reinforcing core of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com