Anti-slide tie-steel pipe pile composite structure for repairing cave-in roadbed and method

A composite structure, anti-slip key technology, applied in infrastructure engineering, roads, roads, etc., can solve problems such as unfavorable road traffic fast and smooth, long concrete solidification time, long construction time, etc. and concrete materials, the effect of speeding up the opening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

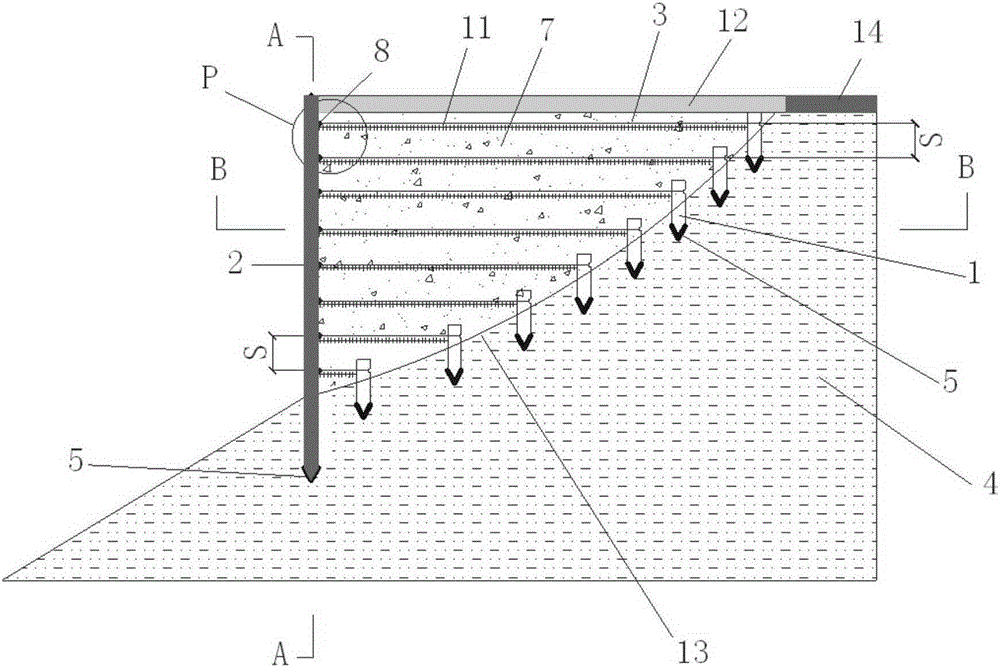

[0038] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

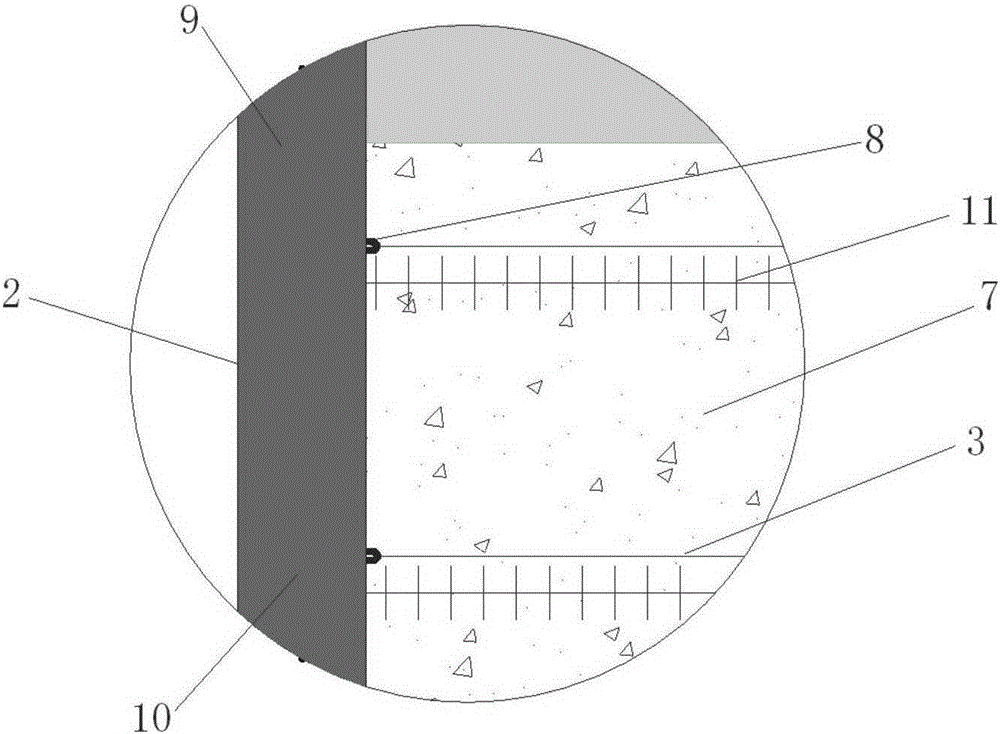

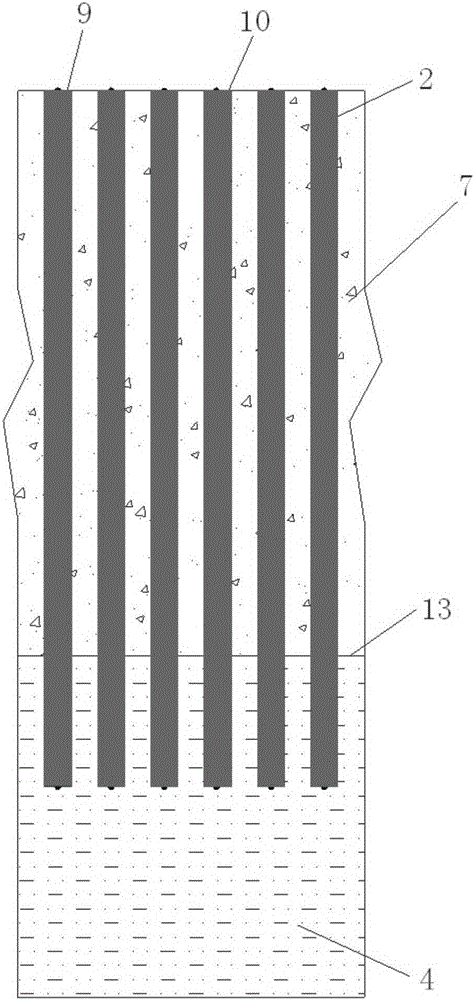

[0039] A kind of anti-skid key-steel pipe pile composite structure for repairing landslide subgrade provided by the present invention, such as figure 1 As shown, it includes anti-skid key 1, prefabricated steel pipe pile 2 and stay cable 3. The lower end of the prefabricated anti-sliding key 1 is fixed in the stable soil 4 below the landslide body, and the upper end is about 20-30 cm higher than the landslide body. In the soil body 4, the upper end is roughly consistent with the road surface elevation. The dragline 3 is flatly laid in the filling 7, and the two ends are respectively fixed on the groove 6 of the anti-skid key 1 and the dragline hook 8 of the steel pipe pile 2, and the dragline connects the three parts into an integral structure.

[0040] Such as figure 1 and Figure 6 As shown, in order to ensure that the anti-skid key 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com