An anti-leakage facility for underground pipelines

An underground pipeline and anti-seepage technology, which is applied to underwater structures, water conservancy projects, artificial islands, etc., can solve the problem of difficult construction of the connection and fixed joints of the anti-seepage layer, many construction procedures of the anti-seepage layer, and difficult construction quality assurance, etc. problems, to achieve the effect of improving site construction efficiency, facilitating construction quality, and reducing the cost of anti-seepage materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

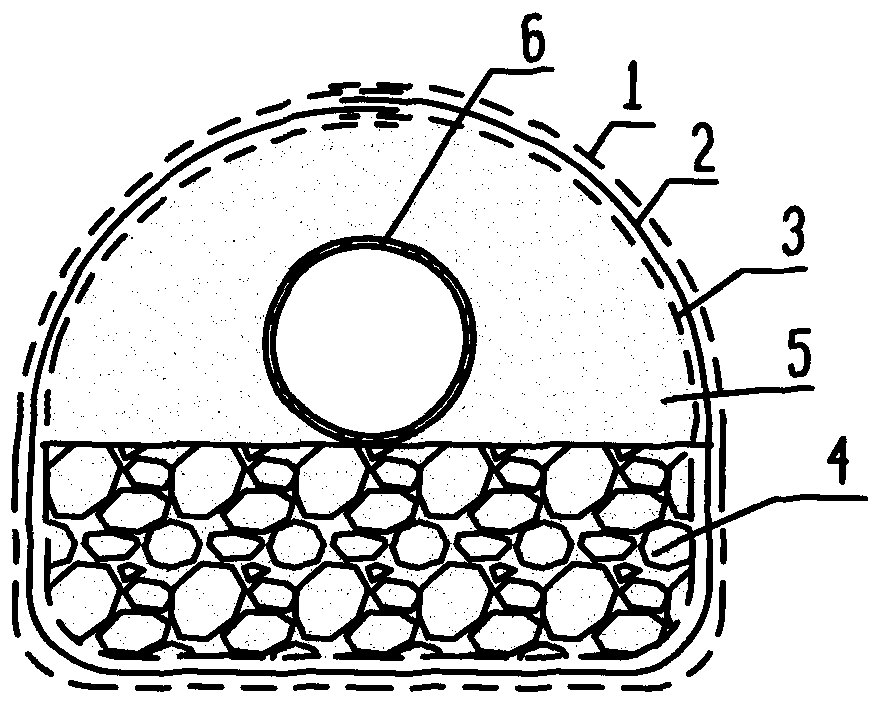

[0034] figure 1 It is a schematic diagram of the structure of the anti-seepage pipeline in the prior art. During construction, the pipe trench is first excavated, the foundation of the pipe trench is compacted, and then the outer protective layer 1 is laid, and the high-density polyethylene film 2 is laid on the outer protective layer 1. An inner protective layer 3 is laid on the density polyethylene (HDPE) film 2, and then a sandstone layer 4 is laid on the inner protective layer 3 and compacted, and a dirty oil or sewage pipeline 6 is laid on the sandstone layer 4, and a dirty oil or sewage pipeline 6 After the water test, fill the medium coarse sand layer 5 on both sides of the pipeline and compact it, then seal the outer protective layer 1, high-density polyethylene (HDPE) film 2 and inner protective layer 3, and finally backfill and compact the trench. The above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com