Connection structure of prefabricated concrete beams and columns

A prefabricated assembly and connection structure technology, applied in building structure, construction, etc., can solve the problems of increased safety hazards, complex connection structure, and longer construction period, and achieve high safety, improved safety, and fast and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

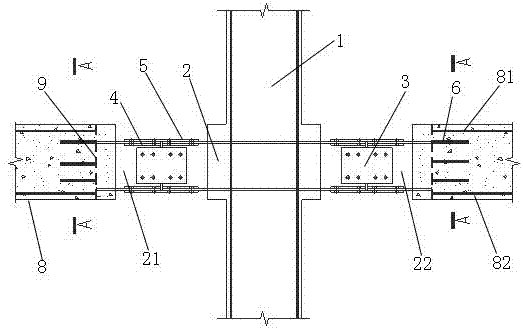

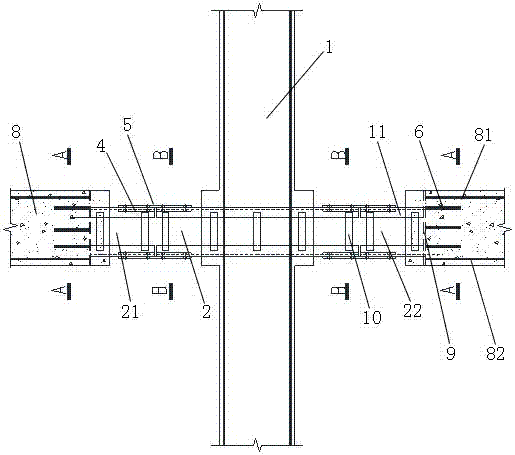

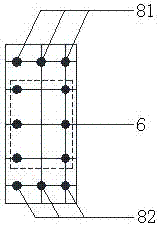

[0038] Such as figure 1 Shown: a connection structure of prefabricated concrete beams and columns, which includes a prefabricated column 1, two prefabricated beams 8, three embedded parts and at least six connecting plates;

[0039] The three embedded parts are all trusses;

[0040] The middle part of the prefabricated column transversely embeds the first embedded part 2, the first embedded part runs through the precast column, and the two ends of the first embedded part protrude from both sides of the precast column, and are provided with longitudinal steel bars and stirrups ;

[0041] The second embedded part 21 and the third embedded part 22 are respectively pre-embedded inside the two prefabricated beams, and the other ends of the two prefabricated parts protrude from the prefabricated beam;

[0042] The two ends of the first embedded part are respectively connected with the protruding ends of the second embedded part and the third embedded part;

[0043] When the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com