A shear wall formwork reinforcing construction method

A formwork reinforcement and shear wall technology, which is applied to formwork/formwork/work frame, formwork/formwork/work frame connector, and on-site preparation of building components, etc. Floor slabs cannot be poured at the same time, to achieve the effect of saving labor, simple operation and fast measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

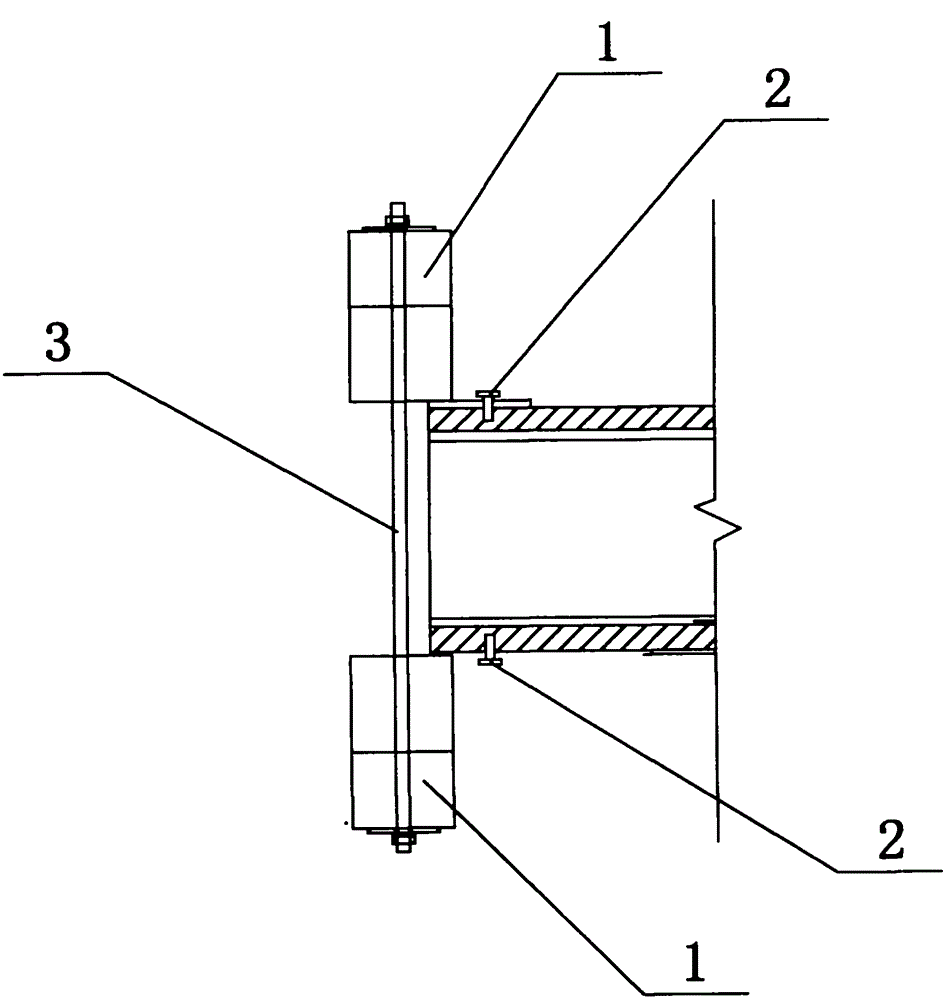

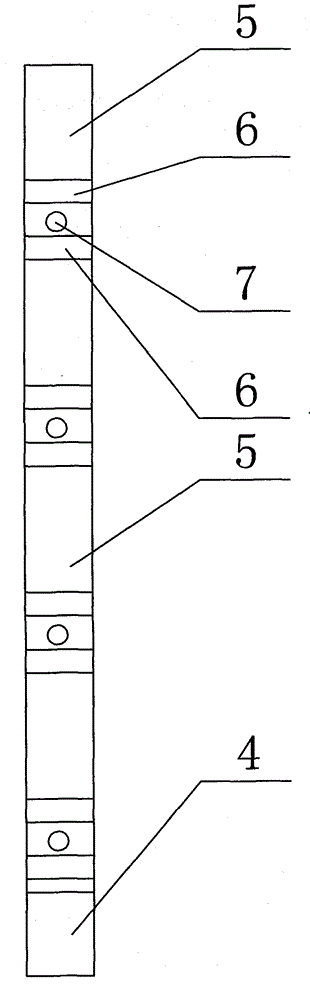

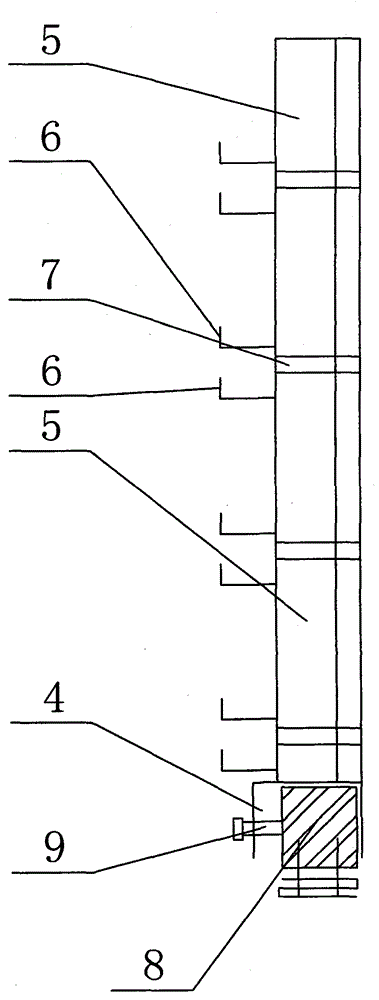

[0024] Such as Figure 1-4 As shown, a shear wall reinforcement formwork structure includes a wall side formwork reinforcement device, a wall formwork reinforcement device and a corner formwork reinforcement device.

[0025] The wall-side formwork reinforcing device includes a connecting rod 3, the two ends of the connecting rod 3 are respectively provided with formwork reinforcements, and the formwork reinforcements are flexibly connected to the formwork. The wall formwork reinforcement device includes a fixed rod at the same height as the wall, and the fixed rod is made of several square steels 5 connected by inserting brackets, and a slot device is arranged at the lower end of the lowermost square steel 5 . The corner formwork reinforcement device includes fixed rods 10 arranged on adjacent walls and perpendicular to each other in directions, and two ends of the fixed rods 10 are respectively provided with reinforcing components.

[0026] In this embodiment, the formwork r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com