Fuel Injector

A fuel injector and injector technology, which is applied to fuel injection devices, special fuel injection devices, charging systems, etc., can solve the problems of slow closing transients and slow opening transients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

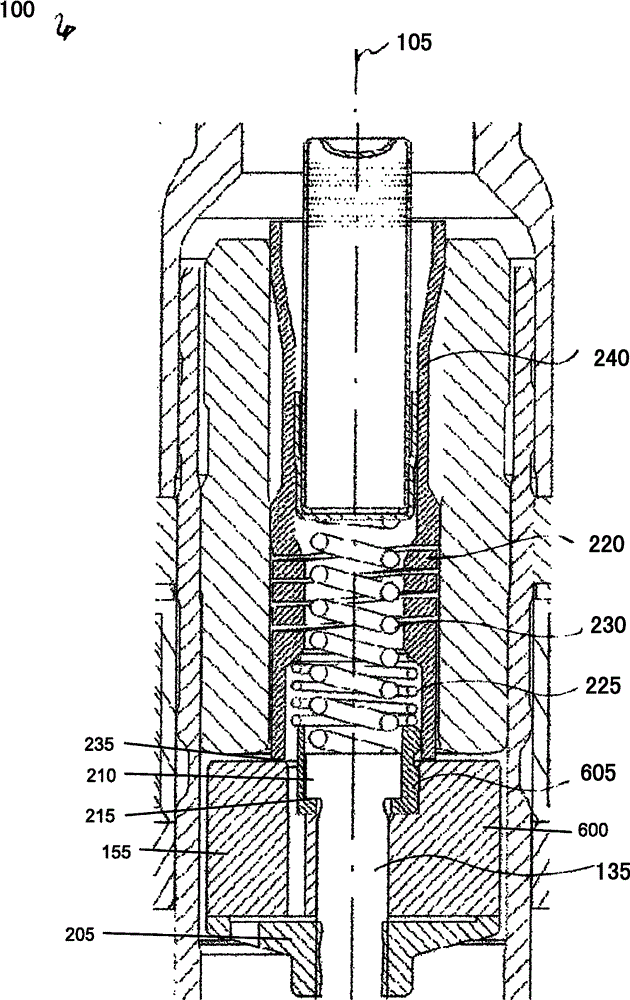

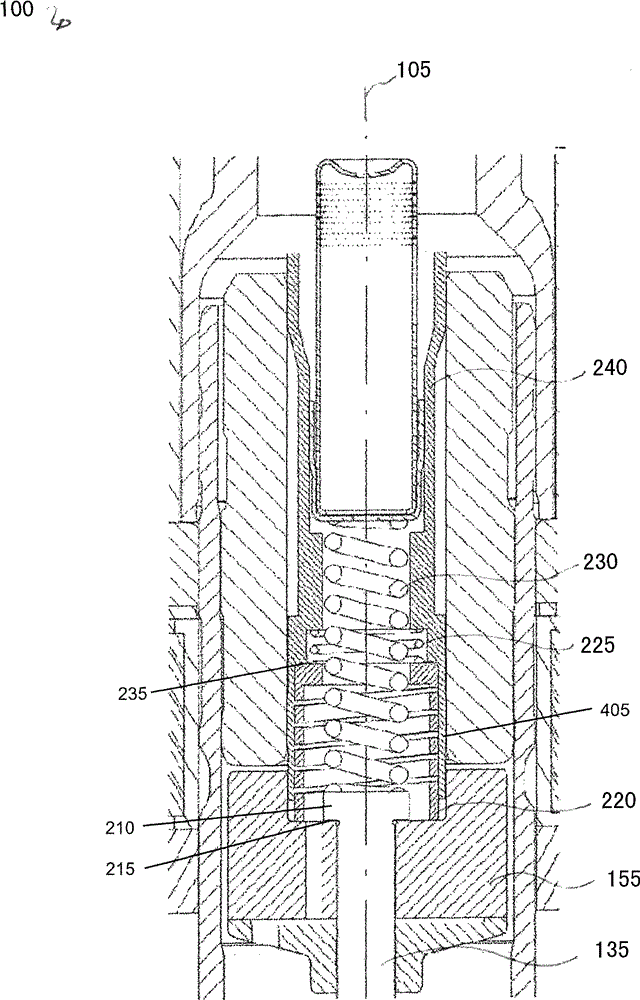

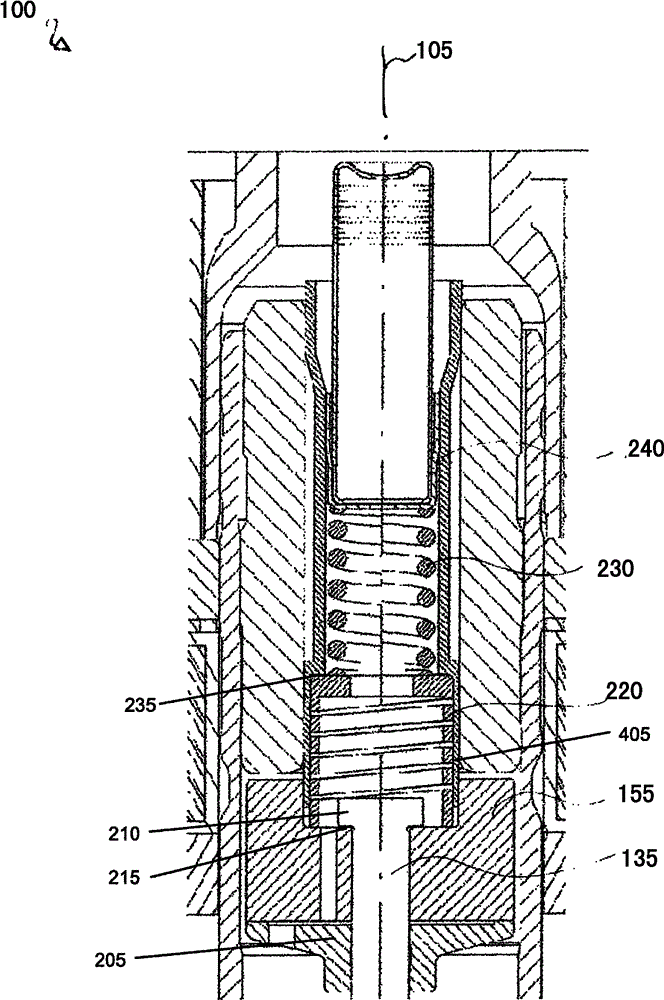

[0029] figure 1 An injector 100 for injecting fuel into a combustion engine according to a first exemplary embodiment is shown in longitudinal section.

[0030]Injector 100 has a longitudinal axis 105, a nozzle end 110, and an opposing supply end 115, sometimes referred to as a fuel inlet end and a fuel outlet end, respectively. The injector 100 includes a valve 120 and an actuator 125 for operating the valve 120 . Actuator 125 is an electromagnetic actuator powered through connector 130 . When power is supplied to connector 130 , fuel flows from supply end 115 through valve 120 and is injected from injector 100 at nozzle end 110 .

[0031] In the illustrated embodiment, valve 120 includes a valve needle 135 movable along axis 105 between an open position 140 in which valve 120 is open and a closed position 145 in which no fuel may pass through valve 120 . The valve needle 135 is accommodated in the cavity of the valve body 122 and is axially displaceable in a reciprocating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com