high pressure water pump

A technology of high-pressure water pump and pump body, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of reducing production efficiency, short service life, and cost, and achieve the effect of high production efficiency and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] For ease of understanding, the technical solutions of the present invention are further specifically described below in conjunction with the accompanying drawings and through embodiments:

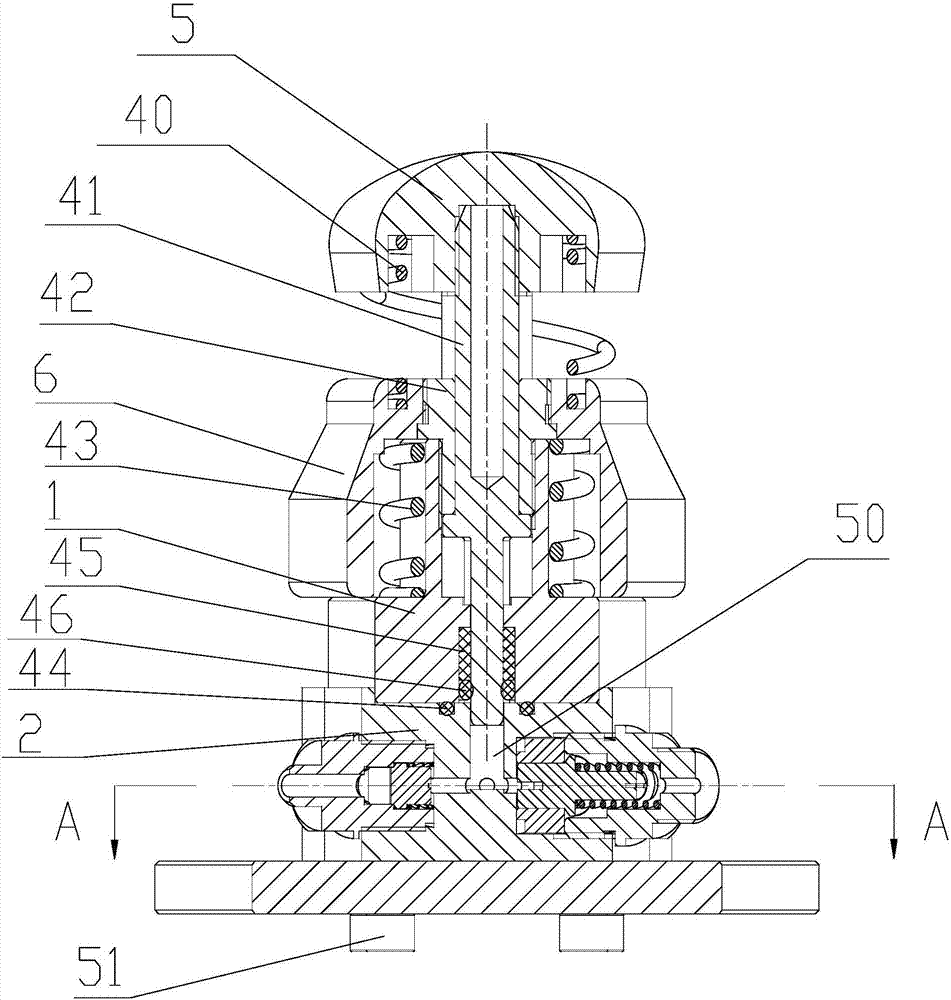

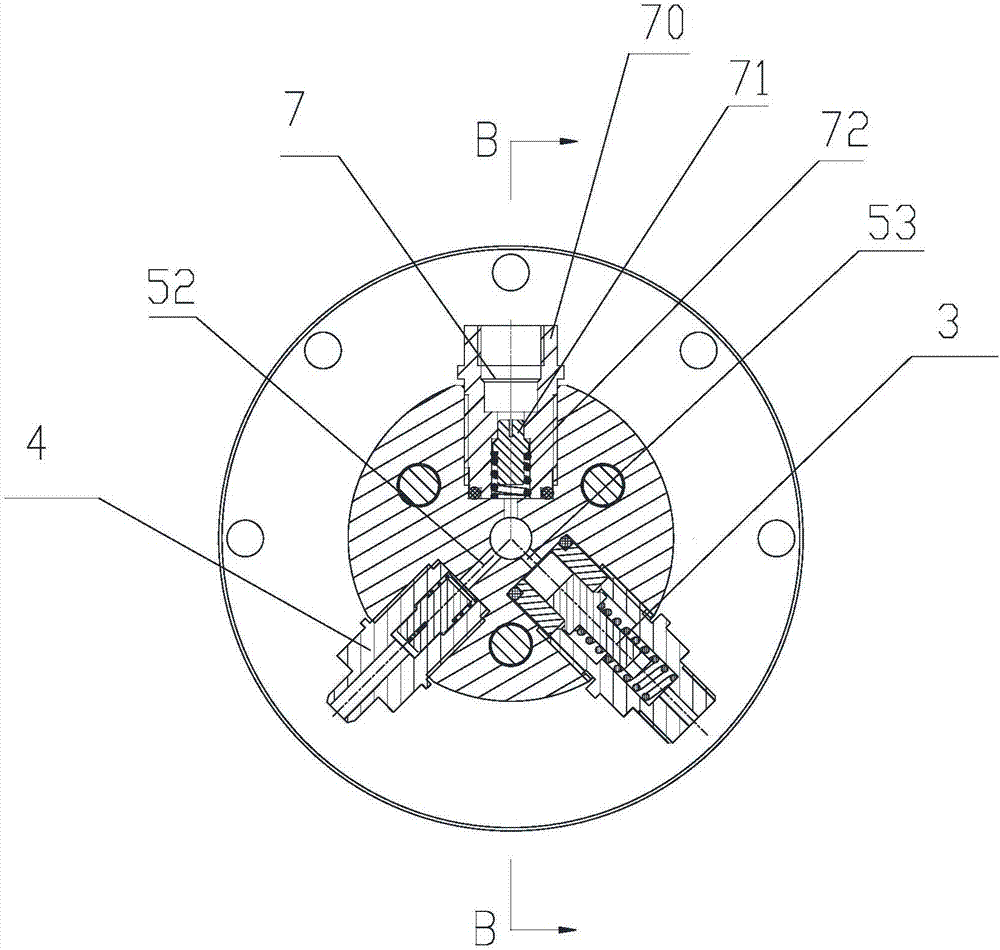

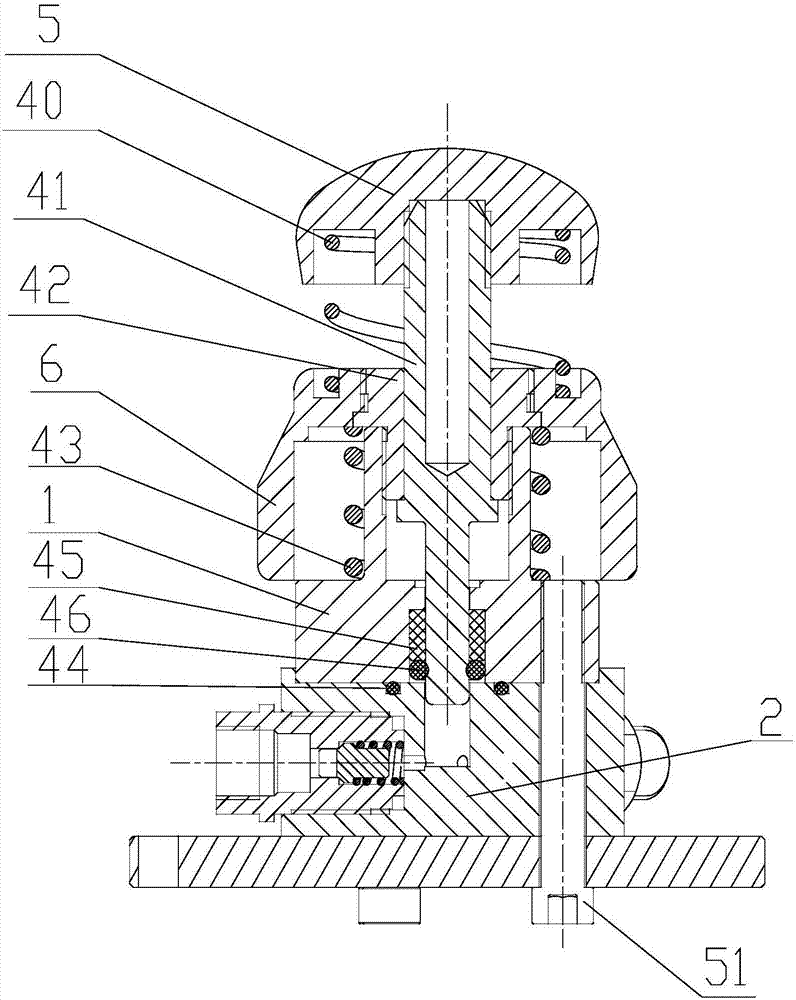

[0032] like Figure 1-Figure 8 As shown, a high-pressure water pump includes an upper pump body 1, a lower pump body 2, an outlet valve 3, an inlet valve 4, a plunger 41, a guide sleeve 42, a bushing 45, a seal 46, an inlet 52 and an outlet 53 and evacuation valve 7.

[0033] The upper pump body 1 and the lower pump body 2 are connected by connecting bolts 51, and a sealing ring 44 is arranged between the upper pump body 1 and the lower pump body 2, and the sealing ring 44 plays a role of sealing and preventing leakage.

[0034] The plunger 41 is sleeved in the upper pump body 1, and the upper end of the plunger 41 is threadedly connected with a percussion cap 5, and the upper end of the upper pump body 1 is provided with an adjustment cap 6, and the working displacement of the plun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com