Design improvement for stamping holder of tapered roller bearing

A technology of tapered roller bearings and cages, which is applied in the field of bearing manufacturing, can solve the problems of low bearing capacity of bearings, and achieve the effects of prolonging life, increasing load, and increasing caliber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

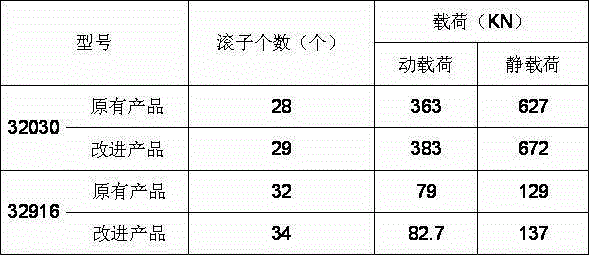

[0007] A tapered roller bearing stamping cage design improvement, the improved design of the tapered roller bearing stamping cage, the design concept is based on not changing the pressure angle of the cage while increasing the diameter of the cage, as long as the distance between the cage and the outer ring raceway The gap between the cages is greater than the radial momentum of the cage. Such a structure can increase the beam width and the number of rollers, thereby increasing the load and life of the bearing. see table 1

[0008] Table 1: Product Comparison

[0009]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com