Stainless Steel Welded Component of Small Backpack Heating Radiator and Manufacturing Method

A technology for welding components and radiators, which is applied in household heating, heating methods, household heating, etc. It can solve problems such as poor welding or breakdown of stainless steel materials, affecting the appearance of stainless steel, and failure to achieve through-connection, etc., to achieve assembly The process is convenient, the welding quality is good, the fusion is reliable and the effect of no leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

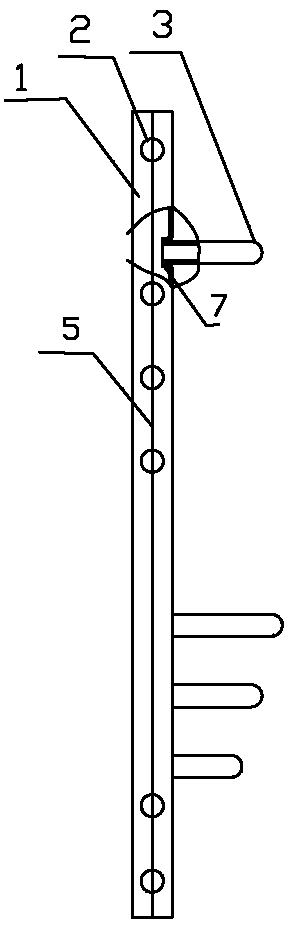

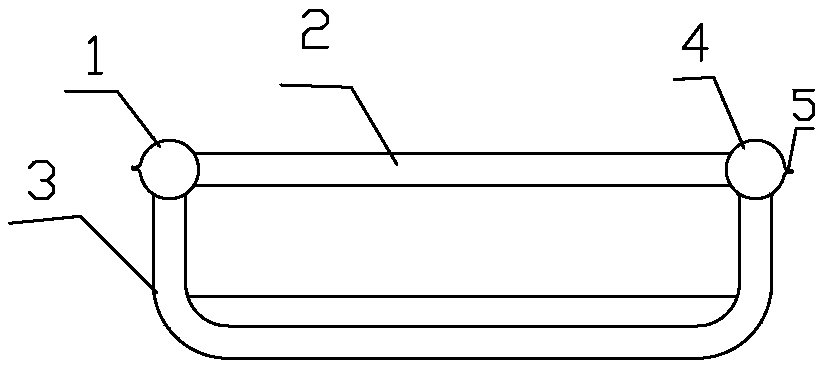

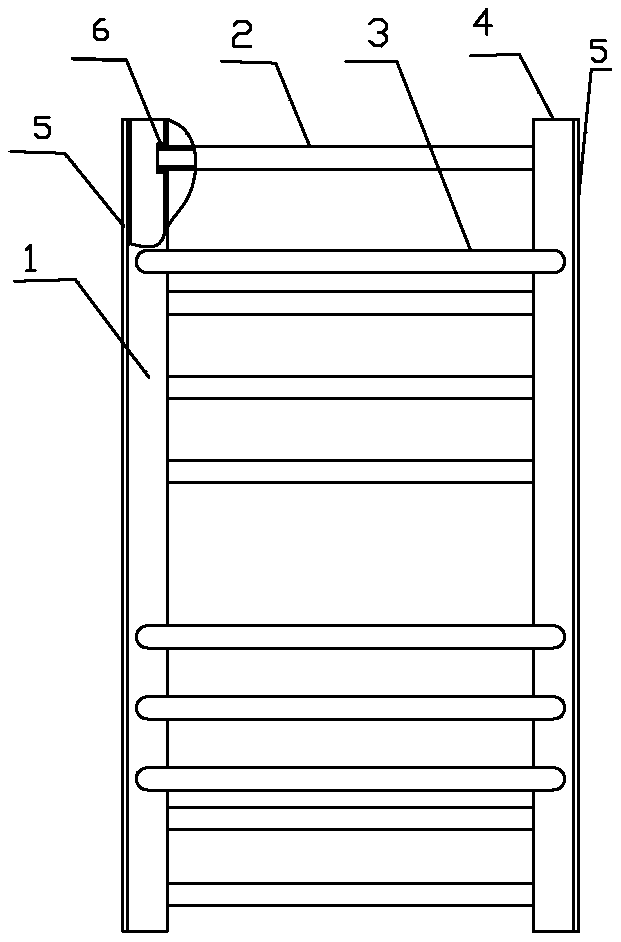

[0032] Such as figure 1 , figure 2 , image 3 Shown:

[0033] The stainless steel welded component of the small basket type heating radiator, which includes vertical connecting pipes 1 and 4 arranged symmetrically from left to right, and a plurality of straight horizontal pipes arranged up and down and distributed on the same vertical plane, such as the straight horizontal pipes in the figure The horizontal pipe 2, the two ends of the straight horizontal pipe are respectively connected with two vertical connecting pipes 1 and 4, and it also includes a plurality of bending horizontal pipes with bending sections at both ends that are not on the same vertical plane as the straight horizontal pipe. Tubes, such as the bent horizontal tube 3 in the figure, the two ends of the bent horizontal tube are respectively connected to two vertical commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com