Level gauge zero-position inspection tester

A technology of zero position inspection and level instrument, which is applied in the direction of instruments and measuring devices, can solve the problems of unstable measurement data due to poor rigidity, inconvenient operation and complex structure, etc., and achieve stable and reliable measurement data, convenient operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

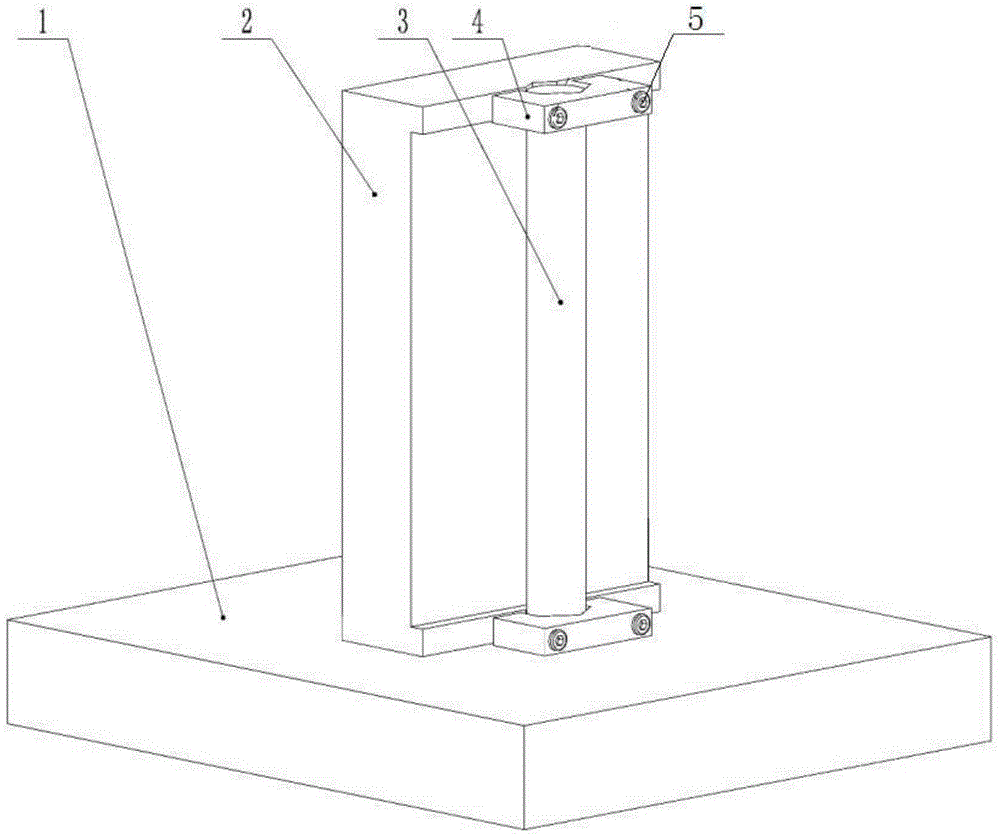

[0018] A level meter zero checker, comprising a flat plate 1 and an instrument main body, the instrument main body includes a rectangular base 2, a mandrel 3 and a pressing device; the mandrel 3 is fixed on the rectangular base by the pressing devices at both ends on the seat 2; the main body of the instrument is placed upright on the flat plate 1 by its own weight. The two side surfaces of described rectangular base 2 are two parallel planes and are perpendicular to the bottom surface; The upper and lower ends of the front of described rectangular base 2 are bosses, and a V-shaped groove is provided in the middle of the boss; The center line of the V-shaped groove is perpendicular to the bottom surface of the rectangular base 2, and parallel to the working surface on the back side of the rectangular base 2. The mandrel 3 is a precision cylindrical rod. The mandrel 3 is fixed in the V-shaped groove of the rectangular base 2 through the pressing devices at both ends. The pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com