Selfcalibration of Capacitive Pressure Sensors with Electrostatic Forces

A pressure sensor, electrostatic force technology, applied in the direction of measuring fluid pressure through electromagnetic components, force/torque/work meter calibration/testing, measuring fluid pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

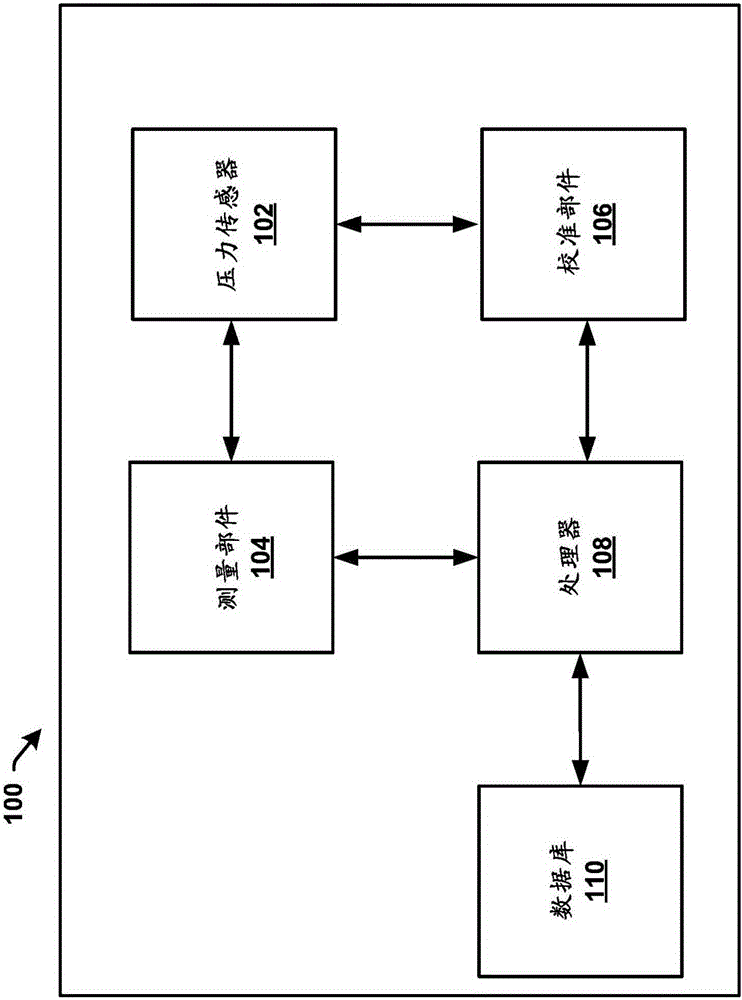

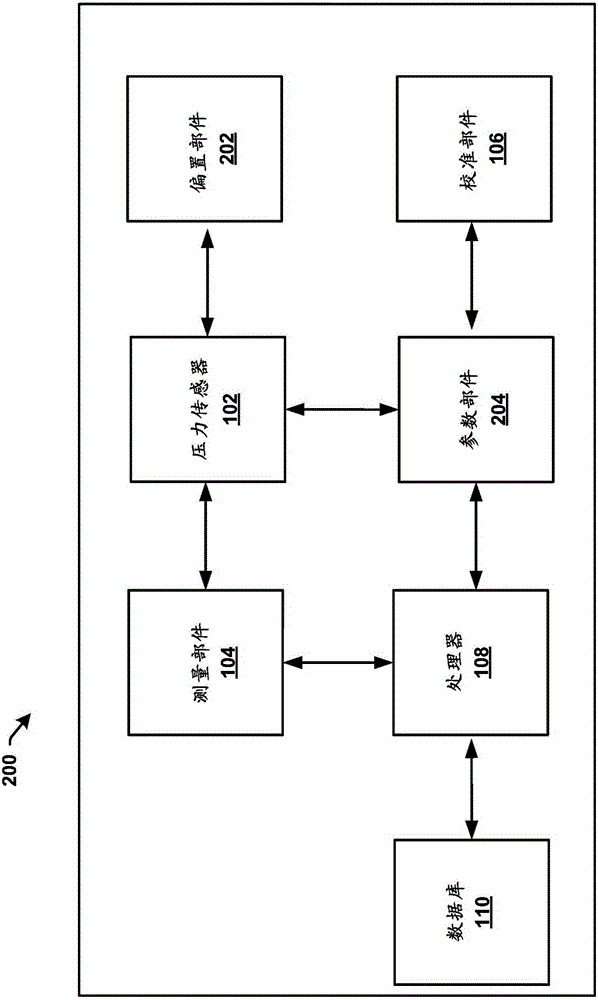

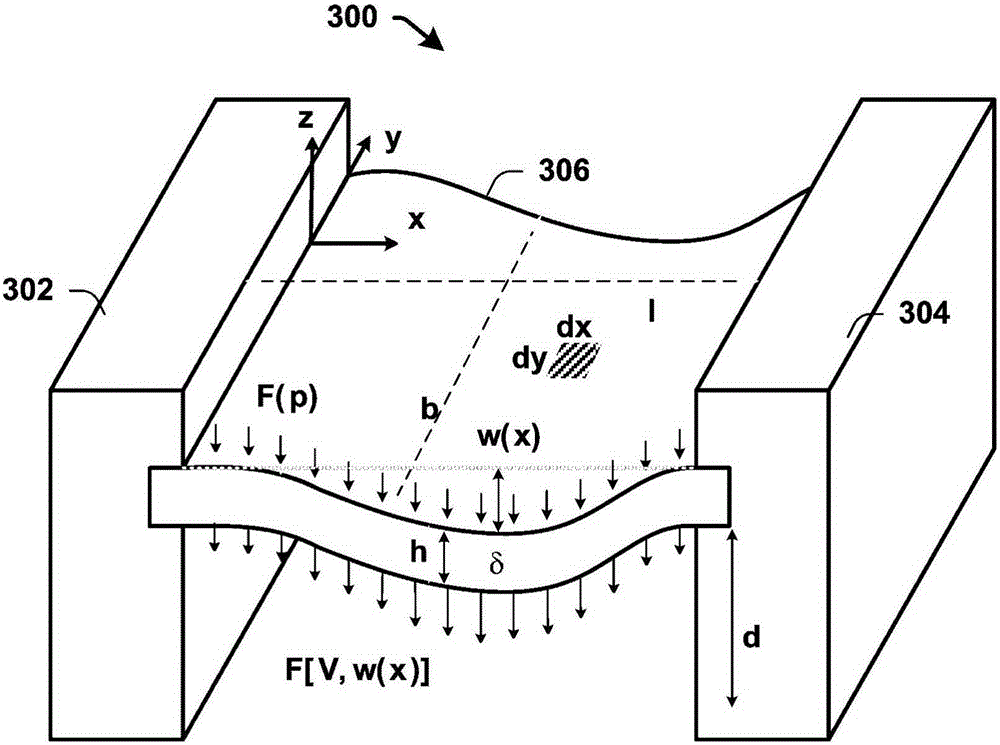

[0018] The present invention will now be described with reference to the accompanying drawings, wherein like reference numerals are used to refer to like elements throughout, and wherein the illustrated structures and devices are not necessarily drawn to scale. As used herein, the terms "component," "system," "interface," etc., are intended to refer to computer-related entities, hardware, software (eg, for execution), and / or firmware. For example, a component may be a processor, a process running on a processor, an object, an executable, a storage device, and / or a computer with a processing device. By way of illustration, applications running on servers and servers can also be components. One or more components can reside within a process and a component can be localized on one computer and / or distributed between two or more computers.

[0019] In addition, these components can execute from various computer readable storage media having various data structures stored thereon,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com