Method for on-line monitoring of damping defect of transformer bushing

A technology for transformer bushings and bushings, which is applied in the direction of testing dielectric strength, etc., can solve the problems of fluctuation and error of measurement results, no online monitoring of oil-paper insulation of transformer bushings, difficulty in applying frequency-adjustable AC voltage, etc. Realize the effect of online monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

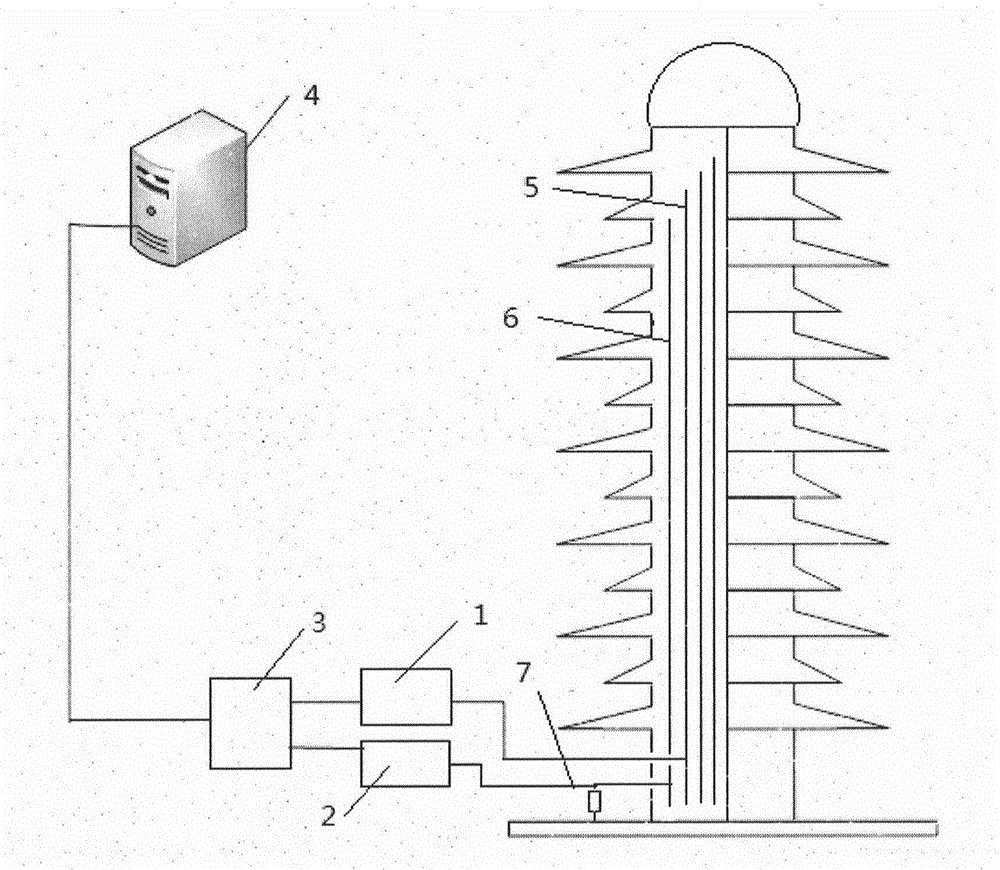

[0027] attached figure 1 It is a schematic diagram of the field application of the specific embodiment of the invention, 1 is the voltage measurement module of the secondary screen 5 of the transformer bushing, and 2 is the ground wire current measurement module of the last screen 6 of the transformer bushing, and these two modules output the voltage and current signals to the signal acquisition Module 3, after A / D conversion, the signal acquisition module 3 transmits to the computer 4, and the computer 4 calculates the dielectric spectrum of the oil-paper insulation of the transformer bushing, and then judges whether the bushing is damp. 7 is a 50 ohm resistor, which is connected in series with the grounding wire of the last screen 6 to sense the current signal and transmit the output to the current measurement module 2 . The voltage measurement module 1 and the current measurement module 2 contain conventional overvoltage protection circuits, amplifiers and level shifters. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com