Optical fiber connector

A technology of optical fiber connector and optical fiber, which is applied in the field of optical fiber communication, can solve the problems of optical fiber damage, affecting the accuracy of optical fiber connection, looseness, etc., and achieve the effect of high assembly accuracy, simplified assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The optical fiber connector of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

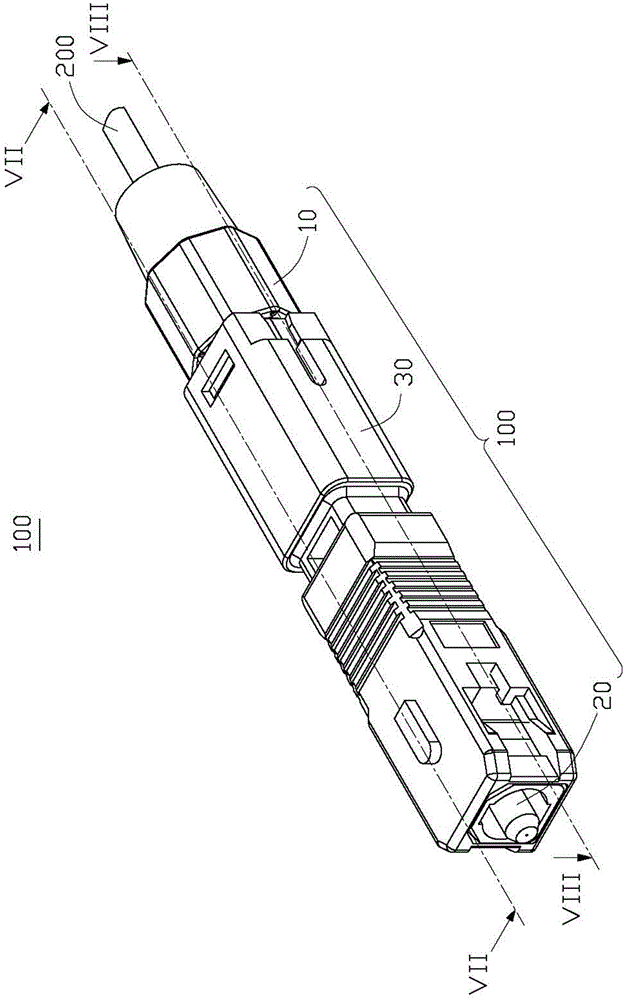

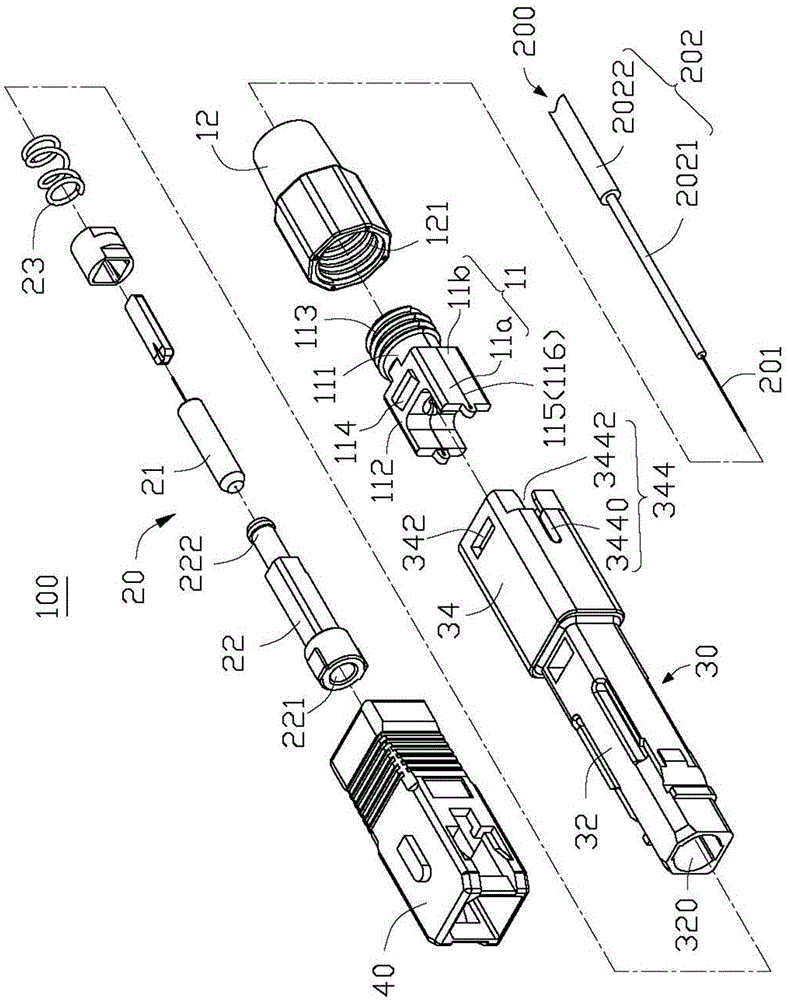

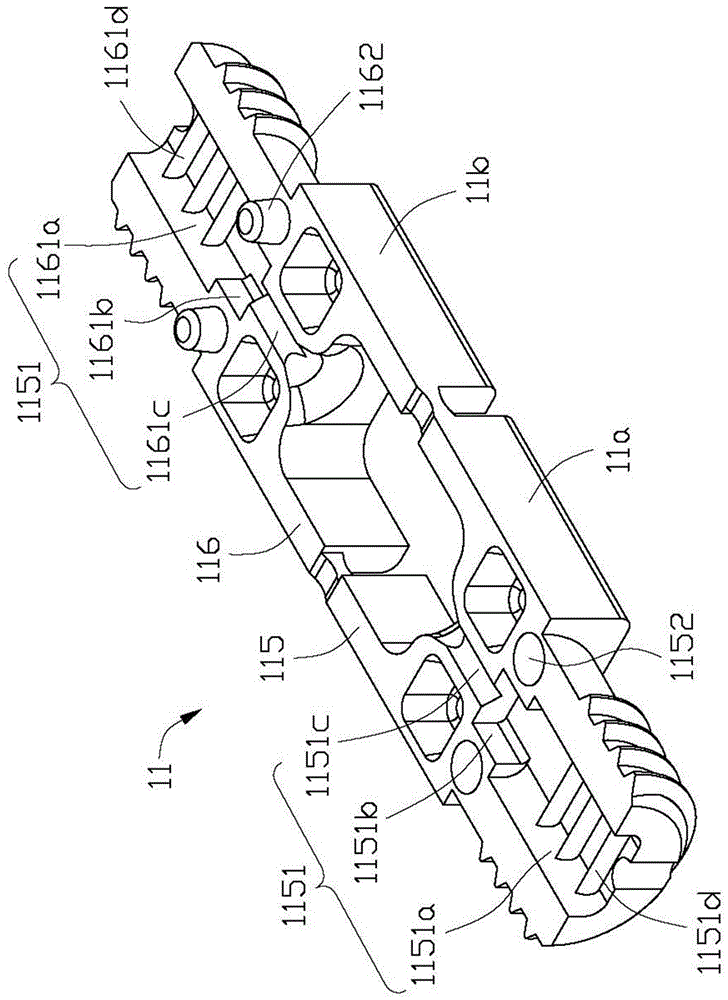

[0020] see Figure 1-3 , the optical fiber connector 100 of the embodiment of the present invention is used to connect the optical fiber 200, and the optical fiber connector 100 includes an optical fiber fixing unit 10, an optical fiber ferrule unit 20, and a fiber optic connector connecting the optical fiber fixing unit 10 and the optical fiber ferrule Housing 30 of unit 20 . The optical fiber 200 includes a core 201 and a cladding layer 202 covering the core 201, the cladding layer 202 is used to protect the core 201, in this embodiment, the cladding layer 202 is further It includes an inner cladding layer 2021 on the inner layer and an outer cladding layer 2022 on the outer layer. When the optical fiber connector 100 is assembled, the cladding layer 202 is peeled off by a predetermined length to expose a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com