Production method of large-size special-shaped aluminum conductive core cable

A technology of conductive wire core and production method, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of easy breakage of monofilament, inability to form cabling, and easy jumping out of the inner layer conductor of the conductive wire core to the outer layer, etc. Achieve the effect of not easy to break, improve quality, and round the cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below.

[0025] A method for producing a large-scale special-shaped aluminum conductive core cable is characterized in that it includes the following steps:

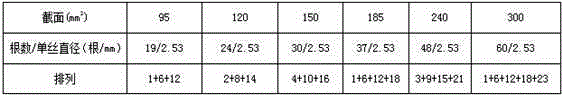

[0026] Step 1: Use an A2 grade φ10mm aluminum rod that meets the national standard, and draw it into a φ2.53mm aluminum monofilament through a sliding aluminum drawing machine;

[0027] Step 2: Put the φ2.53mm aluminum monofilament drawn in step 1 into the annealing furnace for annealing. The temperature in the annealing furnace is controlled at 210-230°C, and the annealing time is 2.5-3 hours. After annealing, the aluminum monofilament The tensile strength of the silk is 130-135N / mm 2 , the elongation rate is 18-20%;

[0028] Step 3: After the aluminum monofilament that has been annealed in step 2 is completely cooled, pour it back and apply drawing oil to form a layer of drawing oil film on the surface of the aluminum monofilament; it can solve the vola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com