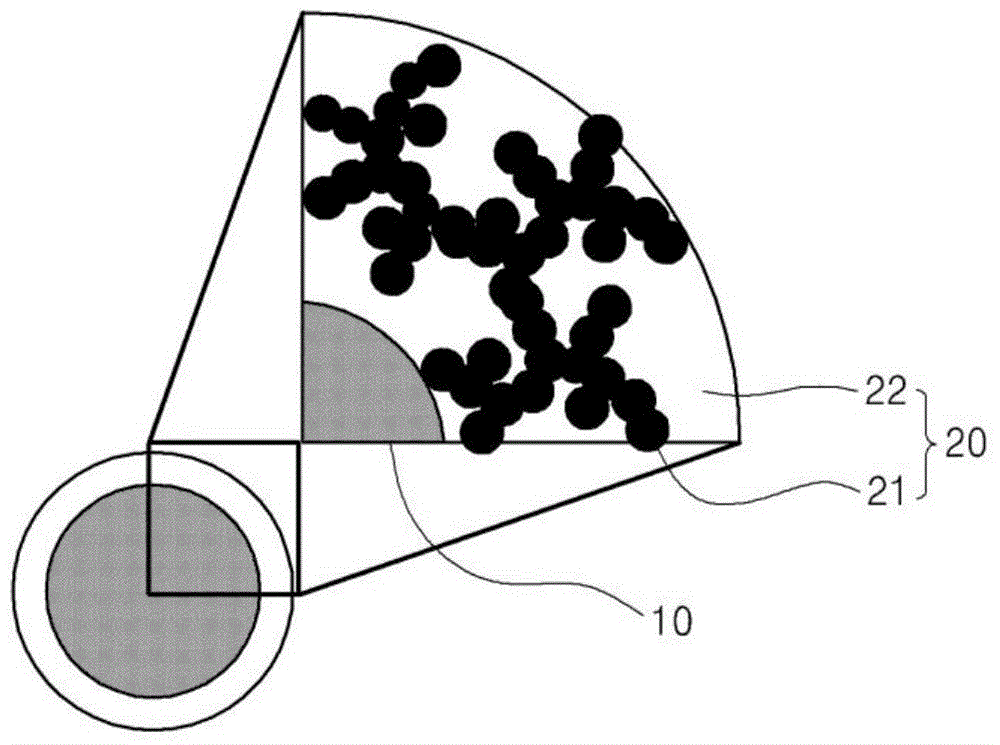

Anode active material for lithium secondary battery and method for preparing same

An anode active and secondary battery technology, applied in the field of anode active materials and their preparation, can solve the problems of blowing out dust, etc., achieve the effects of improving electrical conductivity, improving charging and discharging stability, and avoiding the problem of blowing out dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

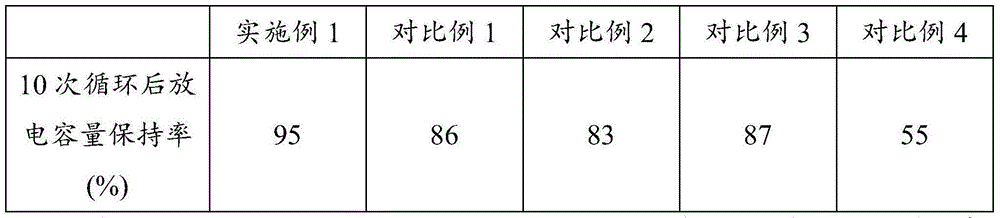

Embodiment 1

[0102] Preparation of anode active materials for secondary batteries

[0103] Synthesis of polyacrylic acid-polyacrylonitrile block copolymers via reversible addition-fragmentation chain transfer using polyacrylic acid and polyacrylonitrile. In this case, polyacrylic acid has a number average molecular weight (Mn) of 4090 g / mol, and polyacrylonitrile has a number average molecular weight (Mn) of 29370 g / mol. 0.25 g of polyacrylic acid-polyacrylonitrile block copolymer was mixed into 44.75 g of said first dispersion medium, N-methyl-2-pyrrolidone (NMP). Into the mixed solution, 5 g of silicon particles having an average particle size of 50 nm were dispersed to prepare a slurry. In this case, the distribution characteristics of silicon were determined by dynamic light scattering (instrument: ELS-Z2, Otsuka Electronics, Japan), and the result showed D50 = 120 nm.

[0104] 120 g of the first carbon source pitch (QI: 4 wt %, SP: 30° C.) was mixed and dispersed in 34 g of the sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com